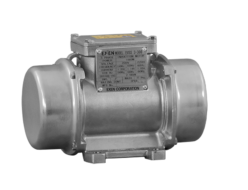

Exen, Pneumatic Vibrator

EXEN EPV35L Piston Vibrator

Products Made In Japan

Manufacturer: EXEN

Model: EPV35L

Pneumatic vibrator with low noise and low air consumption for expanded applications

This product is used for the following applications:

- 01Prevention of blockage of explosive accumulated in chute in explosion-proof area in industrial explosive manufacturer

- 02Prevention of blockage in raw material tank in chemical factory

- 03Knocking off the dust from air filter

- 04Knocking off the fine powder in production line of precision equipment

- 05Use in production line of various automobile parts

Features

Piston vibrator EPV series is a pneumatic vibrator that produces a stable vibration by vertical operation of piston. This is used mainly for prevention of blockage or filling of powder in hopper, tank, or piping chute, and for vibrating source of table vibrator, vibration conveying machine, and vibrating sorting machine. Because piston vibrator EPV series is an oil-free product with environmental friendliness that is excellent in corrosion resistance, it is used in a wide range of industries including pharmaceutical, food, and chemical industries. *Use a normally closed three-way valve for control of activation and stop. *Use a normally closed three-way valve for control of activation and stop.

Industry-topping durability (wear resistance)

Because the wear-resistant processing of EXEN’s unique special technique has been provided for the piston portion in the body, the product takes pride in industry-topping wear resistance.

Oil-free product bringing a sense of safety in food-associated field

Because the piston vibrator is equipped with the exhaust filter and produces less oil mist, it does not have an adverse influence on workplace or handling products. It can be used in a wide range of fields including general industrial equipment field, pharmaceutical, food, and chemical industries.

(Note) Do not use the product with complete dry air. Otherwise, a failure will be caused.

*Use a normally closed three-way valve for control of activation and stop.

Internal silencer system reducing noise

The piston vibrator adopts the internal silencer system to make low noise with a exhaust sound of 62 to 65dB. In addition, air consumption is 9 to 153Ll/min (ANR) based on eco-friendly design, which leads to energy saving in the plant.

Safe explosion-proof specification

Because compressor air is used as power source, the product has low ignition capability like electric type. During operation, air keeps flowing in the cylinder to prevent the entry of dust, allowing the product to be used safely.

Simple installation

The piston vibrator can be installed with one bolt, and can be installed to a place where vibration is required. Also, it can be installed in any direction of 360 degrees.

Applications for vibration conveyance and vibration filling machine

Piston vibrator can be used as power source of vibrating feeder for vibration conveyance, filling and diffusion, and vibration table, by applying the vibration principle of piston movement.

Stepless adjustment of vibration power by changing air pressure

Pneumatic piston vibrator can change the vibration frequency and vibratory force by changing the air pressure. The merit of variable vibration force is to be able to use the same model in a place where the condition of object to which vibrator is installed is different, just by changing the air pressure.

Use in wet site

Although the piston vibrator is not of totally waterproof structure because of its exhaust port, the body except for the exhaust muffler section is of waterproof structure. It can be used in the wet environment by extending the exhaust filter section and installing the filter downward.

Instant stop function facilitating use of weighing machine

Piston vibrator has a function to instantly stop when supplied power is turned OFF, which brings out the effect in vibration conveyance involving weighing.

*This can avoid the adverse effect of resonance at the time of stop.Specification

EPV

Model Working Pressure

(MPa)Frequency

(Hz)Centrifugal Force

(N)Air Consumption

(L/min(ANR))Weight

(kg)EPV12A With

Silencer0.2~0.6 106~164 29~82 9~24 0.14 EPV18 102~149 66~186 17~62 0.34 EPV18L 58~94 82~265 15~54 0.48 EPV25 75~108 147~374 75~153 0.58 EPV35 79~117 304~778 45~145 1.03 EPV35L 51~73 347~921 44~125 1.47 (Imperial System)

Model Working Pressure

(MPa)Frequency

(VPM)Centrifugal Force

(lbf)Air Consumption

(CFM)Weight

(lb)EPV12A With

Silencer0.2~0.6 6,360-9,840 6.52-18.43 0.32-0.85 0.31 EPV18 6,120-8,940 14.84-41.81 0.60-2.19 0.75 EPV18L 3,480-5,640 18.43-59.57 0.53-1.91 1.06 EPV25 4,500-6,480 33.05-84.08 2.65-5.40 1.28 EPV35 4,740-7,020 68.34-174.89 1.59-5.12 2.27 EPV35L 3,060-4,380 78.01-207.04 1.55-4.41 3.24 *EPV model specification is a result with a muffler mounted under our measurement condition.

*Oil free means general air that includes little amount of oil.

*Use a normally closed three-way valve for control of activation and stop.

※ Operating temperature range is 0 ~ 60 ℃.Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model φA B C D E F G H I Tube size EPV12A 27 29.5 (54.9) 1/8 1/8 69.3 (98) 26 M8X10 φ8Xφ6 EPV18 38 40 (65.4) 1/4 89 (116) 36 M10X11 EPV18L 126 (153) EPV25 43.5 48.5 (73.9) 109 (137) 42 M12X12 PV35 56 60.5 (86.5) 1/4 111.5 (138) 55 EPV35L 157.5 (184) (Imperial System)

Model φA B C D E F G H I Tube size EPV12A 1-1/16 1-5/32 (2-5/32) 1/8 1/8 2-47/64 (3-55/64) 3/94 M8X10 φ8Xφ6

(mm)EPV18 1-1/2 1-37/64 (3-37/64) 1/4 3-1/2 (4-9/16) 1-27/64 M10X11 EPV18L 4-61/64 (6-1/32) EPV25 1-23/32 1-29/32 (‘2-29/32) 4-19/64 (5-13/32) 1-21/32 M12X12 PV35 2-13/64 2-3/8 (3-13/32) 1/4 4-25/64 (5-7/16) 2-11/64 EPV35L 6-13/64 (7-1/4)