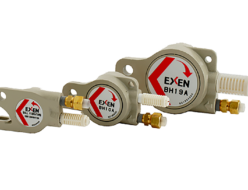

Exen, Vibration motor

EXEN HKM55LFSA High-frequency Vibration Motors

Products Made In Japan

Manufacturer: EXEN

Model: HKM55LFSA

Powerful transmission of vibration by single-touch fixing

This product is used for the following applications:

- Manufacturing of secondary concrete products

- Secondary concreting for tunnels

Features

High-frequency vibration motors, although small and lightweight, produce powerful vibration at high rpm rates and display their full performance in concreting for not only in box culverts and concrete segments but L-shaped retaining walls, PC plates, and other large concrete products as well. These are also applicable to pouring a secondary layer for tunnels, subway works, shield works, and other projects.

Transmitting powerful vibration by single-touch fixing

Fixed with a single bolt that is easy to detach and reattach, these machines transmit vibration stably and pour concrete in a resonance-free and silent manner.

(1) Insert the hook of the vibration motor into the hook base assembly fixed in a mold or something similar.

(2) Lift the motor by using the hook as the support.

(3) Let the motor-fixing bolt into the bolt ditch and fasten the flange nut with a ratchet.

Hermetic structure

Highly airtight, these machines can provide steam curing as installed on a mold. They prevent a decline in insulation and increase ease of operation.

Adjusting centrifugal force achieves silent concreting

The weights (fanlike eccentric weights) installed on both sides of the vibration motor can be adjusted in angle to adjust centrifugal force.

With simple adjustment and a high-frequency inverter, these units produce a centrifugal force that matches the input of freshly mixed concrete, achieving silent concreting.

Using an inverter converts frequency

Equipped with a series of high-frequency inverters (with volume control), these products can be set to a desired frequency setting according to the product dimensions and mold shape.

Setting the high-frequency vibration motor to a desired frequency and a desired centrifugal force provides different vibrations for concreting and finishing, and provides silent concreting that avoids resonance with molds.A sharable hook base

The mounting hook base is shared for HKM55LFA (SA) and HKM75LFA (SA).

When you need to move molds or vary vibration in a factory, you can install the same hook base for them.Specification

HKM-LFA(SA)

Model Input

(W)Voltage

(V)Current

(A)Cord switch Frequency

(Hz)Centifugal force

(kN)Weight

(kg)HKM55LFA 550 48 12.5 No 50~120 8.8 16.5 HKM55LFSA Yes 17.5 HKM75LFA 750 17.0 No 11.6 21.3 HKM75LFSA Yes 22.3 (Imperial System)

Model Input

(W)Voltage

(V)Current

(A)Cord switch Frequency

(Hz)Centifugal force

(lbf)Weight

(lb)HKM55LFA 550 48 12.5 No 50~120 1978 36.4 HKM55LFSA Yes 38.6 HKM75LFA 750 17.0 No 2608 46.9 HKM75LFSA Yes 49.1 *Product masses include that of the cable (1.7Kg) and the intermediate switches (0.9Kg).

Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model H L W HKM55LFA 240 218 213 HKM55LFSA HKM75LFA 305 213 218 HKM75LFSA (Imperial System)

Model H L W HKM55LFA 8.4 9.4 8.6 HKM55LFSA HKM75LFA 8.6 1’0″ 8.4 HKM75LFSA Product dimensional drawings