Air Knocker, Exen

EXEN RKVS15 Stainless Steel Knocker

Products Made In Japan

Manufacturer: EXEN

Model: UT612

Recommendation for food, medical, and chemical industries. Automatic hammering equipment for blockage prevention

This product is used for the following applications:

- 01• In the factory of drinking water manufacture: RKVS installed to prevent the clogging of tea leaves in SUS trough

- 02Elimination of adhesion on wall surface in the coffee bean roasting machine

- 03Elimination of ratholing in resin pellet hopper

- 01Improvement of ejection of film materials

- 02Elimination of salt clogging

- 03Elimination of sugar clogging

Features

The stainless steel knocker, a sister product of high-performance Air Knocker series, is an air knocker with stainless steel body that prevents adhesion and blockage of powder in hopper or tank. The stainless knocker is suitable for pharmaceutical, food, and chemical industries or other sites where corrosion resistance and safety are required.

The unique operating principle of this product is that the force of compressed air causes the piston to energetically strike the base surface, which eliminates the adhesion or blockage of powder. Also, the stainless knocker operates on only the supply air, which is excellent in safety and economics. Like Air knocker series, the stainless steel knocker has an adjustable impact force by the supply air and the relay piping function. (RKVS15 does not support the relay piping.)Stainless steel body excellent in corrosion resistance

The stainless steel knocker consists of the body, standard base, mounting bolts and others, all of which are made of stainless steel material. It is suitable to install a site in food, chemical, and pharmaceutical industries and a site where corrosion resistance and sanitation are required.

Adjustable impact force

In the air stainless steel knocker series, just changing the pressure of supply air allows the impact force to be changed by the special mushroom valve (patented). The air pressure is increased if the blockage cannot be eliminated, and is decreased if the impact force is too strong. Moreover, the adjustment of pressure is effective in reducing noise. Even if wrong selection of model results in excessive or poor capability during installation work, such a problem may be solved by adjusting the impact force. Thus, the adjustable impact force mechanism is appreciated in the field.

*The blue portion in the center is “mushroom valve”

Relay piping allowing multiple units to be used simultaneously

Air knocker is equipped with relay piping function (patented) in which one control panel can operate more than one unit simultaneously. In the similar way, one controller or the control panel dedicated to knocker can use more than one unit. Thus, the introduction of relay piping will decrease the facility cost because the number of control panels in overall facilities can be reduced.

*For the combination of flow aid system, also refer to “The combination of flow aid system”

*Automatic control can be performed by attaching a solenoid valve (AG43-02-4-02G) before AOC-1B (air supply side).

*N2 tube size

RKVS30・40・60:Φ8XΦ6

*RKVS15 type does not support the relay piping.Operating principle of Air knocker

1.The compressed air flowed into the knocker is first supplied to the valve chamber to depress the mushroom valve and then is stored in the accumulator.

2.When the three-way valve is actuated to exhaust the air from the valve chamber, the compressed air in the accumulator moves the mushroom valve upward.

3.When the mushroom valve moves, the compressed air in the accumulator depresses the piston energetically, which strikes the base surface. That impact force eliminates the adhesion or blockage of powder.

*For the operating principle of air relay knocker, also refer to “The operating principle of flow aid system”

RKVS30

Reduction in size and weight providing wide range of applications

The body of stainless steel knocker RKVS15 type is of very small size, 34mm in external diameter, 110mm in total height, and 430g in weight. It can be installed to a small powder container or a chute section that never been able to be installed, and can facilitate the prevention of blockage every corners of facilities.

Adoption of directionally-adjustable and removable push one joint (only for RKVS20 or lower)

Small size models of RKVS15 and RKVS20 employ the directionally-adjustable push one joint that can be easily removed. As a tube mounted to the models, small-diameter tube is employed for easy routing, instead of the tube with an external diameter of 8mm for the conventional models. (An external diameter of 4mm for RKVS15, and 6mm for RKVS20)

The kits for which RKVS15 and RKVS20 can be used in the conventional controller with a discharge opening diameter of 8mm are attached respectively.

※RKV20 / Opecon / Push one joint

Simple structure and high durability

The stainless steel knocker series have durability supported by high design basis and have a simple structure, which provides almost maintenance-free performance and requires no additional spare parts. In long-term delivery record of this air stainless steel knocker series, customers have appreciated its maintenance-free performance with almost no failure.

Installable depending on the container condition (RKVS15 type)

The air stainless steel knocker RKVS15 type can be installed with one bolt (M10). Therefore, it can be installed on your idea such as installation with the dedicated stay bracket, with no knocker mounting stay provided on the container or with no soldering of container.

Support for attachment of exhaust filter and extension of exhaust position

Because the stainless steel knocker is oil free, it can be used in a clean room. If exhaust air becomes a problem in the field, the exhaust air can be discharged outside of the clean room through an extended tube because the exhaust hole of body is tapped. If the extended tube cannot be used, the dedicated filter is available. (Exhaust extension parts and filter are optional)

Various types of dedicated controllers for knockers are available

The dedicated control panel is available for operation of air knocker series and stainless steel knocker series. The control panels include the air operation controller AOC-1B type that can start operation readily without electric power, the timer control panel for solenoid valve control KSE1 type that controls the interval between impacts and the number of impacts, and the control panel HKE series, or the control panel EKE5000 with free input voltage specification from 100 to 240VAC. In addition, the fully air controlled control panel HKA5000A for explosion-proof area is available. (Option)

From left、AOC-1B/KSE1/HKE1100A/HKE5100/EKE5000/HKA5000A Specification

RKVS

Model Working Pressure

(MPa)Stroke Cycle

(time/min)Air Consumption

(L/time)(ANR)Stroke Energy

(N・m)Impulsive Force Weight

(kg)(kg・m/s) Hammer pound

(lb)RKVS15 0.3-0.7 1-60 0.03-0.06 2.7-5.9 0.3-0.5 Mini Hammer 0.43 RKVS20 0.04-0.10 4.3-8.3 0.6-0.8 Below0.6 0.8 RKVS30 0.05-0.13 5.5-13.1 1.2-1.8 Below1.0 1.6 RKVS40 0.15-0.37 9.2-22.3 2.6-4.0 1.0-1.5 4.2 RKVS60 0.33-0.77 20.6-49.0 6.9-10.6 1.5-3.0 10.4 (Imperial System)

Model Working Pressure

(PSI)Stroke Cycle

(time/min)Air Consumption

(cf/time)Stroke Energy

(lbf・ft)Impulsive Force Weight

(lb)ft・lbf/s Converts into

Hammer pound

(lb)RKVS15 44-102 1-60 0.001-0.002 2.0-4.4 2.2-3.6 Mini Hammer 0.9 RKVS20 0.001-0.004 3.2-6.1 4.3-5.8 Below0.6 1.8 RKVS30 0.002-0.005 4.1-9.7 8.7-13.0 Below1.0 3.5 RKVS40 0.005-0.013 6.8-16.4 18.8-28.9 1.0-1.5 9.3 RKVS60 0.012-0.027 15.2-36.1 49.9-76.7 1.5-3.0 22.9 *The dimensions of stainless steel knocker are the same as those of relay knocker.

*The weight includes that of base.Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model ΦA G H I O Tube size RKVS15 34 Rp1/8 86 (24) Rp1/8 Φ4XΦ2 (Imperial System)

Model ΦA G H I O Tube size RKVS15 1.3 Rp1/8 3.4 (0.9) Rp1/8 Φ4XΦ2

mm

Related Products

-

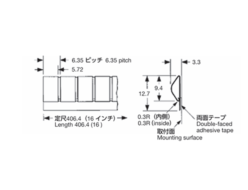

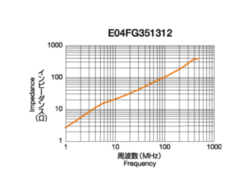

Seiwa E04FG351312 Ferrite Cores for FPC and FFC FG Types EMC Products

-

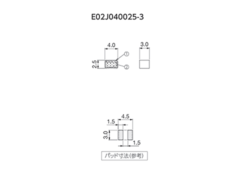

Seiwa E02J040025-3 Automatic Mounting Gasket EMC Products

-

Seiwa E01S04 EMC Products

-

Urakawa ZTN44×55-60054 ZTN, ZTE Series EN, UL Certified Products

-

Seiwa E04SR200935AB Ferrite Core Split Cores SR, SRM and SRS Types EMC Products

-

Seiwa E04FG351312 FG Types Ferrite Cores for FPC and FFC