Exen, Table Vibrator

EXEN TV300-MW Compact Table Vibrator (Electric/Pneumatic)

Products Made In Japan

Manufacturer: EXEN

Model: TV300-MW

Table vibrator showing great activities in various filling works!

This product is used for the following applications:

- 01.Filling of ceramics

- 02.Filling of activated carbon into deodorant filter

- 03.Filling of imitation brick

- 04.Medical massage

Features

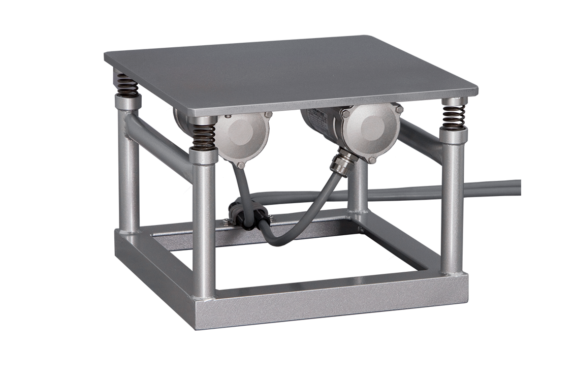

The vibrational principle of table vibrator is that external vibrating machine (e.g., vibration motor, air vibrator) is mounted on the table upper frame and the workpiece loaded on the head is vibrated together with the container. The purpose is to produce a vibration for filling into the container, defoaming, demolding, penetration enhancement, diffusion, mixing, vibration tester, and others of workpiece. In the case of industrial machinery industries, there are various types of workpieces to be filled, such as ceramic powder, resin pellet, carbon, iron powder, silica sand, cosmetic mascara. As for the necessary vibration force, the basic standard load is set for the weight of loading item, but minor vibration is enough for some of workpieces and there are various vibration frequencies effective for moving the workpiece. (An appropriate vibration condition can be checked in the demonstration machine.)

As vibrating sources, electric compact vibration motor (single-phase 100V/three-phase 200V) and pneumatic piston vibrator series are available. The feature of single-phase 100V type is convenience provided anywhere. The feature of three-phase 200V type is that the use of inverter control panel MFC1 model allows an appropriate vibration to be applied to a workpiece. In addition, the feature of pneumatic type is that adjustment of air pressure allows an appropriate vibration to be applied. Although compact model series are introduced in compact table vibrator series, table vibrator for heavy load can also be designed and manufactured. Please contact EXEN.

*Compact table vibrator is estimated each time and is built-to-order.

*The product with the top surface of table resinated is optional.(Extra cost)Various types of vibration sources are available

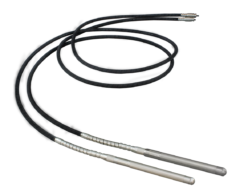

As vibrating sources for compact table vibrator series, electric single-phase 100V vibration motor and three-phase 200V vibration motor, and pneumatic piston vibrator are available.

Electric or pneumatic type can be selected depending on the power supply conditions of equipment location. For the electric vibration motor, compact vibration motor with stainless steel body is adopted.

Single-phase 100V type is EKM1S-2P model and three-phase 200V type is EKM1.1-2P model.

Both of them comply with IP code 66, and are washable and excellent in corrosion-resistance.

Size and material of upper frame

The table upper frame is prepared for manufacture according to the specification that defines dimensions of table head of compact table vibrato to 200mm in length and 300mm in width.

Also, the material of upper frame is specified to stainless steel SUS304 and とpolyacetal resin as standard specification. Selection can be made depending on the application. (polyacetal resin is an additional option)

The product with different dimensions or other material specified can be manufactured. (Ask for details)

Stainless steel SUS304(left) / polyacetal resin(right)

Features of electric and pneumatic types

Because the combination with inverter enables the vibration frequency to be changed, the electric three-phase 200V type allows the vibration frequency to be selected depending on the property of loading workpiece, which will achieve the high-efficient workability.

The pneumatic vibrator allows the vibration force and vibration frequency to be changed by changing the air pressure, which will expand the application.

Also, the pneumatic type can be used safely in an explosion-proof area.Table basic form 1: With one vibration motor

The vibration condition when one vibration motor is mounted on the table upper frame is the circular vibration.

This is used for workpiece in which the circular vibration by one motor is more effective.

This has an advantage that the price is lower than the table with two motors.

Also, if the pneumatic piston vibrator is used, the vertical vibration can be secured with one motor.

Table basic form 2: With two vibration motors

The vibration condition when two vibration motor is mounted on the table upper frame is the vertical vibration. The vertical vibration provides a stable vibration because of less movement of the workpiece container, which has shown the field-proven performance.

Also, because this is one face type, the mold can be fixed to the top surface of table and the molds with various shapes can be loaded.

If the pneumatic piston vibrator is used, the vertical vibration can be secured with one motor.

Principle of vertical vibration

Mounting tow vibration motors to the upper frame allows vertical vibration to be produced.

Rotating two vibration motors in opposite direction each other to synchronize the rotational frequency of two vibration motors will offset the centrifugal force in a horizontal direction, which produces the centrifugal force only in a vertical direction to provide the vertical vibration.

If there is a large difference in rotational frequencies, the vertical vibration is not provided because of no synchronization.

Correct arrangement of loading items on table

The arrangement of correct loading position is the position where the gravity center of table is matched with that of loading item in the resultant force axis of centrifugal force of vibrator.

Examples of applications and product workpieces

Table vibrator is used for various applications in industrial machinery field. In addition to the following filling, diffusion, penetration enhancement, defrosting, desalination, defoaming, and demolding, there are other unknown fields for vibration applications, which raises expectations.

1. Filling of powder: silica sand, ceramic powder, resin pellet, carbon, iron powder, mascara, powder

2. Diffusion of powder: removal of dust on lens, adhesive agent, diffusion of powder

3. Penetration enhancement: table for pickles, pickles of Chinese cabbage, pickles of radish

4. Desalination enhancement: desalination of fish egg

5. Defrosting enhancement: defrosting enhancement of fish

6. Demolding aid: demolding of form

7. For various testers: mixing tester, concrete tester, conveyance tester, medical testerControl panel

For TV-MW series (three-phase, 200V), use the MFC-1 equipped with inverter. (optionally available)

Specification

Model Vibrator Vibration Motor Specifications Permission

Load Capacity

(kg)Allowance

Loading weight

(kg)Note Model Units Voltage

(V)Output

(W)Current

(A)

(50Hz/60Hz)Frequency

(Hz)

(50Hz/60Hz)Centrifugal Force

(kN)

(50Hz/60Hz)Rating TV300-MW EKM1.1-2P 2 3-phases

200V11 0.11/0.10 45.1/53.3 0.07/0.11 Continuous 10 14.4 Open TV300C-MW 17.9 Enclose (Imperial System)

Model Vibrator Vibration Motor Specifications Permission

Load Capacity

(lb)Weight

(lb)Note Model Units Voltage

(V)Output

(W)Current

(A)

(50Hz/60Hz)Frequency

(VPM)

(50Hz/60Hz)Centrifugal Force

(lbf)

(50Hz/60Hz)Rating TV300-MW EKM1.1-2P 2 3-phases

200V11 0.11/0.10 2,706/3,198 16/25 Continuous 22 31.7 Open TV300C-MW 39.5 Enclose Product dimensional drawings

Product dimensional table

Model L W H TV200-P 200 200 217 TV200C-P TV200-M 177 TV200C-M TV300-P 300 300 250 TV300C-P 254 TV300-MW 192 TV300C-MW (Imperial System)

Model L W H TV200-P 7.9 7.9 8.5 TV200C-P TV200-M 7 TV200C-M TV300-P 11.8 11.8 9.8 TV300C-P 10 TV300-MW 7.6 TV300C-MW Kouei is the Official Distributor/Agent of EXEN.

Other items of Exen

Request the quotation for Exen