Exen, Table Vibrator

EXEN TVAW Series Table Vibrator

Products Made In Japan

Manufacturer: EXEN

Model: TV55AW-10, TV55AW-12, TV75AW-12, TV75AW-15, TV110AW-15, TV110AW-18

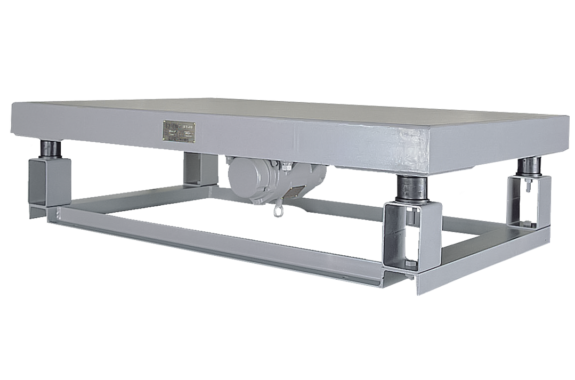

With a powerful vibrating unit on its table, this vibrator saves labor in pouring concrete in manufacturing secondary concrete products.

This product is used for the following applications:

- 01.Used to fill bottles with salt in salt manufacturers’ factories

- 02.For filling in ceramic molding

- 03.To fill molds in refractory lining factories

- 04.To fill sintered metal with powder

- 05.To load fish food

Features

This vibrator has a powerful vibrating unit on its rigid table. It is used mainly to load and defoam freshly mixed concrete for U-shaped grooves, boundary blocks, segments, PC plates, and other secondary concrete products; the vibrator is also used in production lines for foods, drugs, and other products to load powder. The vibrator can also be used to promote penetration in lightly salted pickles and other foodstuffs and to desalt salted food ingredients.

The principle of the vibrating table is to mount a workpiece-containing container on a vibrating upper frame and to vibrate the container itself. A developer of vibrators for construction, we at EXEN Corporation enjoy a long history and a rich track field in loading freshly mixed concrete in secondary concrete product factories. We are also committed to table vibrators for industrial machinery by taking advantage of our previous experiences. (Products manufactured to order)A rich track record of delivery and experience

Taking an example of our deliveries of vibration tables, our secondary concrete product factories has been loading — as URC products — boundary blocks and block-type retaining walls, and — as RC products — service and drainage canals, side ditches, tunnel segments, artificial reefs, and other products weighing tens of kilograms to tens of tons. For industrial machinery, we have been loading sand, powder ceramics, resin pellets, carbon, and other materials, promoting penetration in lightly salted Chinese package pickles and pickled radishes, desalting fish eggs, and the like. Our table vibrators have widely been used for testing as well and also been employed as loading testers and vibration testers for transportation.

Best suited for pouring concrete in secondary concrete product factories

The vibration table can be set to give the best acceleration and frequency for compacting concrete, thereby compacting concrete products with an equal, neat-surfaced finish. This compactor can greatly improve the working environment, product quality, productivity, and cost in secondary concrete product factories.

Selectability of vibration types

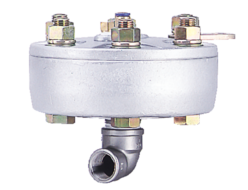

The vibration table can be set to circular or vertical linear vibration by selecting a particular type of vibrator and a method for installing it. In general, if you mount an electrical KM vibration motor or an air ball vibrator on the top frame of the table, the result is circular vibration. If you install two vibration motors or one air piston vibrator on the top frame of the table, you can obtain vertical vibration.

Both vibration modes can be used to load concrete while vibrating it. Of the two, vertical vibration is the better suited and does not move molds or allow the eccentricity of loads (workpieces). Circular vibration is suited for agitating and mixing workpieces and allows them to be used according to particular purposes.Selectability of table shapes

Vibration tables basically come in two different shapes. One is a single-surface type where you mount a mold on one table and work on it, and the other is a separate type where you place two tables in parallel and place one mold on that set of two tables. The separate one is suited for long molds and similar applications, and advantageous in that it suffices to have only a small vibration table.

Adaptable to a wide range of superimposed loads

Vibration tables come equipped with motors capable of managing containers of various sizes and workpieces having superimposed loads of tens of grams to tens of tons. Smaller ones are air-operated vibrators to KM vibration motor types of about 30 W, while larger ones (KM series) are with separate tables of the order of 3,000 W to accommodate superimposed loads of up to 5 tons. We have once delivered hydraulic vibration tables for 20 tons of RC segments for the Tokyo Bay Aqua-Line.

Changing frequencies to produce even higher effects

The KM vibration motor series used for vibration tables are three-phase induction motors. An inverter can therefore be used to change frequency. Varying it makes it possible to set the frequency to the setting best suited for loading and mixing a particular workpiece, adjusting the frequency to finish the surfaces of a loaded material neatly, and the like, thereby satisfying our customers. Air-operated vibrators are, on the other hand, controlled by air pressure.

Using air springs in damping and production lines

The top vibration frame and the bottom stand of the vibration table are generally equipped with springs, rubber damper, or air spring. Exen’s air springs excel greatly in damping, resulting in efficient vibration. In addition to damping, air springs are also used as actuators for production lines. This production line functions as follows: in roller transportation lines, mold containers sent on a table are regarded as actuators and lifted with an air spring. The container is then separated from the roller, loaded by vibration, and then the air spring is lowered and the container is returned to the transportation roller and sent. This line is widely used for secondary concrete product lines.

A free weight system for a wider range of operating conditions

The free weight system of the vibration table is an Exen technology where a KM vibration motor is run forward and in reverse to allow selection of two vibration force levels (a system that achieves vibrations about 60% and 100% of the standard centrifugal force). This system allows workers to do work without changing pendulum settings when there are two superimposed loads, thereby ensuring high convenience. When combined with an inverter, this product can pave the way for an even wider range of operating conditions.

Enhanced accompanying optional designs

As examples of optional designs that accompany our vibration tables, various operational technologies are available to ensure even higher convenience in our table vibrations, such as when the tables are frequently moved by forklift, when the rubber mold plate on the table top or the table vibrator are to be controlled by radio to protect against noise. Therefore please consult us.

Specification

Model Motor Permission Weight

(kg)Table Dimension(mm) Weight

(kg)Model Nos. L W H TV55AW-10 KM55-2PB 4 1700 1000 300 611 270×2 TV55AW-12 1200 300×2 TV75AW-12 KM75-2PFB 2500 320×2 TV75AW-15 1500 360×2 TV110AW-15 KM110-2PFB 3000 500 586 540×2 TV110AW-18 1800 610×2 (Imperial System)

Model Motor Permission Weight

(lb)Table Dimension(ft) Weight

(lb)Model Nos. L W H TV55AW-10 KM55-2PB 4 3747.8 3’3″ 1’0″ 2’0″ 595.2×2 TV55AW-12 3’11” 661.4×2 TV75AW-12 KM75-2PFB 5511.5 705.5×2 TV75AW-15 4’11” 793.7×2 TV110AW-15 KM110-2PFB 6613.8 1’8″ 1’11” 1190.5×2 TV110AW-18 5’11” 1344.8×2 Dimensions, installation, control panel

Product dimensional drawings