Exen, Vibration motor

EXEN Vibration Motor EKM-2P Series (2 Pole Single-phase 200V)

Products Made In Japan

Manufacturer: EXEN

Model: EKM1.1-2P

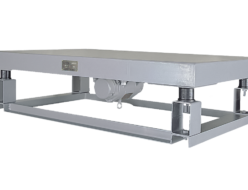

Water washing OK! Vibration motor in size of canned coffee

This product is used for the following applications:

- 01Installation to a small hopper that requires periodic cleaning in the food-processing plant

- 02Prevention of blockage of recycling raw materials in public bath

- 03Prevention of adhesion on wall surface in the ceramic pigment hopper

- 04Vibration for amusement (movie)

Features

Water-washable EKM1.1-2P type with all stainless steel body for preventing adhesion or clogging in a small container or chute in response to the demand of further miniaturization of vibration motor for food, chemical, and pharmaceutical industries. The product body is 128mm in total length and 2.0kg in weight, the smallest size in the series, which is expected to be applied to a small container in each industry.

(Installation is possible with two M6 bolts.) Vibration motor generates a centrifugal force vibration by rotation of eccentric weights at both ends of rotor shaft. 2P series are mainly used for mounting directly to the powder container to prevent the adhesion or blockage or to eliminate the clogging by alleviating compaction, or fused as a table vibration equipment for filling. EKM1.1-2P of three-phase and 200V is a vibration motor that can be used in wide applications by, for example, combining it with inverter to select the appropriate vibration for workpiece.Compact and full oil-free

EKM1.1-2P type is a compact, full oil-free, and electric-driven vibration motor. It can be used in various fields as a modern version of energy-saving type because air supply is not required.

Stainless steel body excellent in corrosion resistance

All components of the vibration motor EKM1.1-2P type, including body and side cover, are made of stainless steel casting. It is suitable to install a site in food and chemical industries and a site where corrosion resistance is required.

Water washing is possible

With the structure with IP code 66 as well as all stainless steel materials, the vibration motor supports water washing complying with sanitary specifications.

Description of IP code 66

Having a totally-enclosed drip-proof structure equivalent of IP code 66, the product can be used safely outdoors.

Display of IP code

IP (International Protection code) means Ingress Protection of electric equipment and cabinet for solid foreign object and water defined in the IEC standards 529.

IP6 (first code) 6 (second code)

The first code 6 means the protection for human body and solid foreign object. The degree of protection is no internal ingress of dust.

The second code 6 means the protection against ingress of water. The degree of protection is that no harmful influence is exerted from ocean waves or direct jet flow of water from any direction.Reduction in size and weight providing wide range of applications

EKM1.1-2P type is a product in wider range of applications on your idea. Because its compact body can be installed with two bolts, EKM1.1-2P can be installed to a small powder container, and a chute section or a small area that never been able to be installed, which prevents the blockage at every corners of facilities

Support for fall prevention wire

The vibration motor optionally comes with the attaching portion for fall prevention wire to prevent the vibration motor from falling if a mounting bolt is removed or damaged.

Adjustable frequency

The frequency can be adjusted by using the general-purpose inverter of three-phase 200V output. Set an appropriate frequency depending on the application and purpose of vibration.

Usable in wide range of applications

The vibration motor is generally used for preventing the blockage of powder. Furthermore, it can be installed the equipment that requires vibration in vibration conveyance, vibrational diffusion, and vibration compaction by applying the usage.

Specification

Model Output

(W)Voltage

(V)Input

Frequency

(Hz)Current

(A)Frequency

(Hz)Centrifuga Force

(kN)Set bolt

(mm)Weight

(kg)50Hz 60Hz 50Hz 60Hz 50Hz 60Hz EKM1.1-2P 11 200

3-phases50/60 0.12 0.11 46.5 56.7 0.07 0.11 6 2.0 (Imperial System)

Model Output

(W)Voltage

(V)Input

Frequency

(Hz)Current

(A)Frequency

(VPM)Centrifuga Force

(lbf)Set bolt

(Inch)

(mm)Weight

(lb)50Hz 60Hz 50Hz 60Hz 50Hz 60Hz EKM1.1-2P 11 200

3-phases50/60 0.12 0.11 2790 3402 15.74 24.73 1/4

64.4 *The weight of cable 1M is included.

*The centrifugal is fixed because the angle of weight cannot be adjusted.

*Japanese specification only.Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model L1 L2 L φC EKM1.1-2P 70 58 128 9.9 (Imperial System)

Model L1 L2 L φC EKM1.1-2P 2-3/4 2-9/32 5-3/64 25/64