Fluke

Fluke 6109A / 7109A Portable Calibration Baths

Manufacturer: Fluke Calibration

Model: 6109A / 7109A

Features

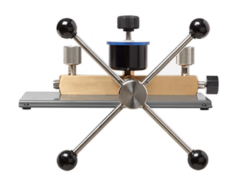

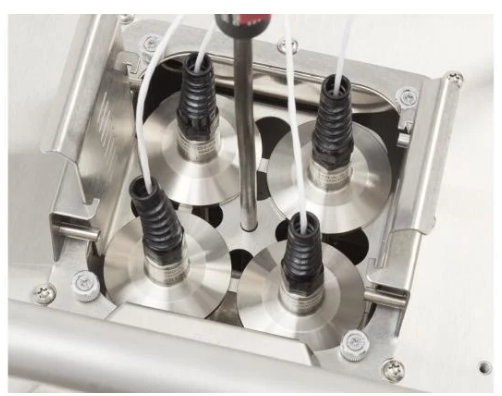

- Calibrate up to four tri-clamp sanitary sensors per batch with ± 0.1 °C temperature display accuracy.

- Covers a wide temperature range: 6109A: 35 °C to 250 °C

- 7109A: -25 °C to 140 °C.

- Stainless steel casing that withstands harsh cleaning solutions; it’s easy to transport and maintain.

Specifications

| Specification | Details |

|---|---|

| Size | Height: 382 mm (15 in) Width: 242 mm (9.5 in) Depth: 400 mm (15.7 in) |

| Weight | 6109A: 16 kg (35 lb) 7109A: 20 kg (44 lb) |

| Fluid volume | 2.5 liters (0.66 gallons) |

| Fluid working area | 75 mm x 75 mm (3 in x 3 in) |

| Maximum fluid depth | 154 mm (6.1 in) |

| Factory calibration | Traceable NVLAP-accredited calibration included |

Temperature Specifications

The temperature specifications describe the Absolute Instrumental Uncertainty at 95% level of confidence (coverage factor k = 2) within one year from calibration. The specifications include environmental temperature effects from 13 °C to 33 °C.

| Specification | 6109A | 7109A |

|---|---|---|

| Range (at 25 °C ambient temperature) | 35 °C to 250 °C | –25 °C to 140 °C (–15 °C cover off) |

| Accuracy (maximum permissible error) | 0.1 °C | 0.1 °C |

| Display resolution | 0.01 °, 0.001° | 0.01 °, 0.001° |

| Stability | 0.015 °C | 0.01 °C |

| Typical uniformity | 0.03 °C up to 200 °C 0.04 °C above 200 °C | 0.02 °C |

| Repeatability | 0.04 °C | 0.04 °C |

| Typical heating time | 35 °C to 100 °C: 25 minutes 100 °C to 250 °C: 45 minutes | –25 °C to 25 °C: 35 minutes 25 °C to 140 °C: 55 minutes |

| Typical cooling time | 250 °C to 100 °C: 35 minutes 100 °C to 35 °C: 55 minutes | 140 °C to 25 °C: 45 minutes 25 °C to –25 °C: 75 minutes |

| Typical settling time | 15 minutes | 10 minutes |

Process Input Module specifications (-P models)

The Input Module specifications describe the Absolute Instrumental Uncertainty at 95% level of confidence (coverage factor k = 2) within one year from calibration. The specifications include calibration uncertainty, linearity, repeatability, resolution, stability, and environmental temperature effects from 13 °C to 33 °C.

| Function | Range | Accuracy (Maximum Permissible Error) |

|---|---|---|

| Reference input resistance | 0 Ω to 42 Ω 42 Ω to 400 Ω | 0.0025 Ω 0.006% |

| Reference input temperature | –25 °C to 250 °C | 0.007% + 0.015 °C |

| Resistance sensing current | 1 mA | 8% |

| DUT 4-wire resistance | 0 Ω to 31 Ω 31 Ω to 400 Ω | 0.0025 Ω 0.008% |

| DUT 3-wire resistance accuracy | 0 Ω to 400 Ω | 0.12 Ω |

| Thermocouple mV | –10 mV to 100 mV | 0.025% + 0.01 mV |

| Reference junction temperature | 0 °C to 40 °C | 0.35 °C |

| Thermocouple temperature | –25 °C to 250 °C 0 °C to 250 °C | J: 0.44 °C E: 0.44 °C L: 0.42 °C K: 0.49 °C N: 0.57 °C U: 0.48 °C T: 0.53 °C M: 0.48 °C R: 1.92 °C D: 1.12 °C S: 1.88 °C G/W: 3.34 °C C: 0.84 °C |

| mA range | 0 mA to 22 mA | 0.02% + 0.002 mA |

| Loop power | 24 V dc | ± 6 V |