FREEBEAR CORPORATION

Freebear Corporation Custom Made Products Clean Room

Manufacturer: Freebear Corporation Ltd.

Model : Custom-made products (Clean room)

Design and development of custom-made products for to meet the needs of customers

The freebears can be customized according to the customer’s requirements for shape, size and purpose. Please feel free to contact us.

Applications meeting diverse demands

■ Applicable to precision equipment production lines where cleanliness may affect product quality

They are used in the production lines of LCD, PC internal parts, mobile phone parts, solar panels, medical equipment, CD-DVD, etc.

Custom-made examples

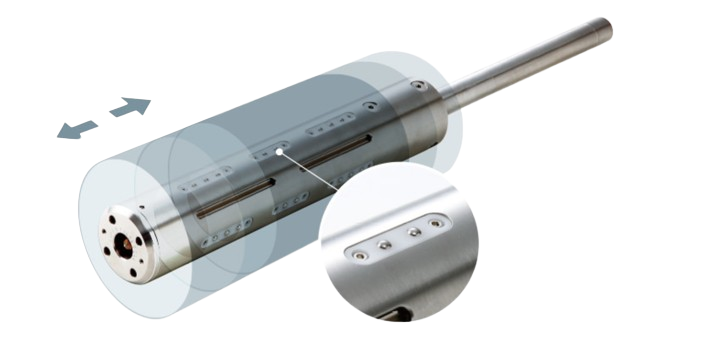

■ Packaging-related equipment manufacturing company

Air shaft with freebear

- By using the freebears, work burden of handling heavy objects has been reduced at the time of roller exchange.

- In addition, it is now possible to perform fine adjustment and positioning as the roller can be moved smoothly.

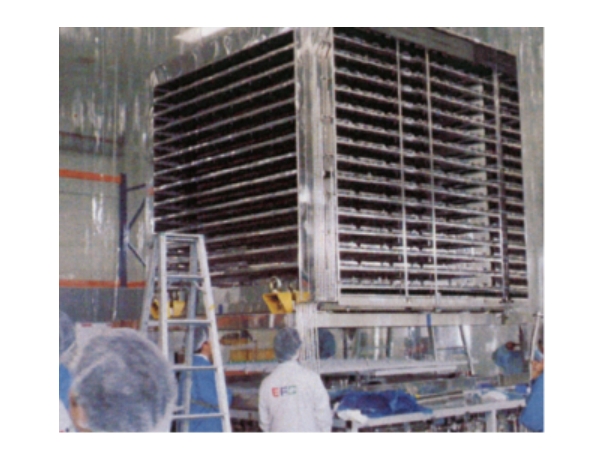

Precision equipment manufacturers Introduced to glass substrate, medical devices, and equipment manufacturers

- The freebears for clean room have been widely applied in environments requiring a higher level of cleanliness.

- They have provided the high quality for demanding conditions from manufacturing plants of precision equipment like liquid crystal panels, solar panels and PC boards to the medical field like operating rooms.

- The wide applications are the reliable evidence for the high praise that our products have won.

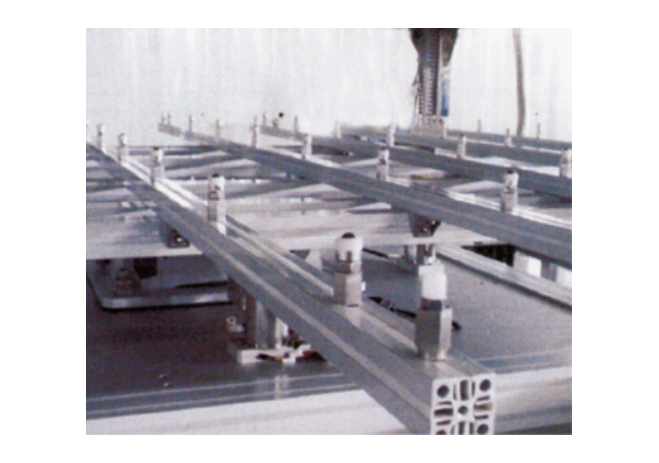

■ Liquid crystal panel alignment device

■ Liquid crystal panel drying equipment

Special-ordered products suitable for existing equipment and meeting even minor requirements

- With our unique customization system, custom-made can also be made to suit various devices.

- We can meet dimensions, specifications, materials and various other requirements.

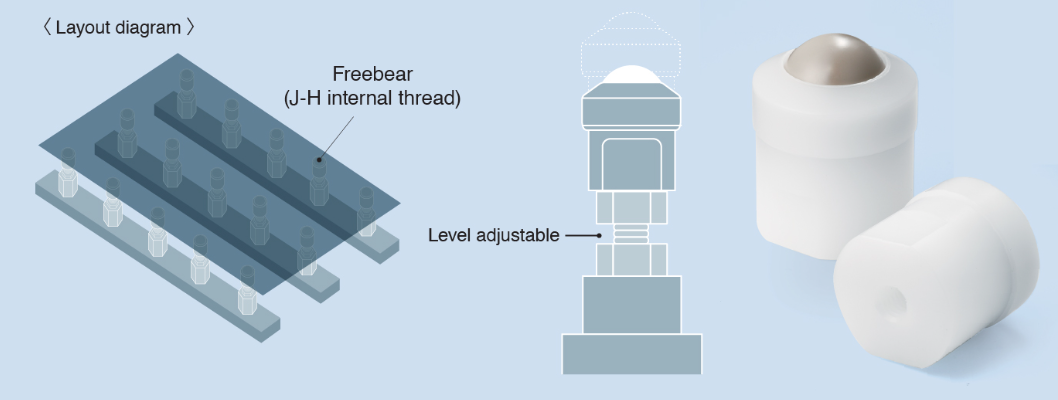

J-H Internal thread

Suitable for the conditions that there is a restriction on the mounting location or a need for height adjustment.

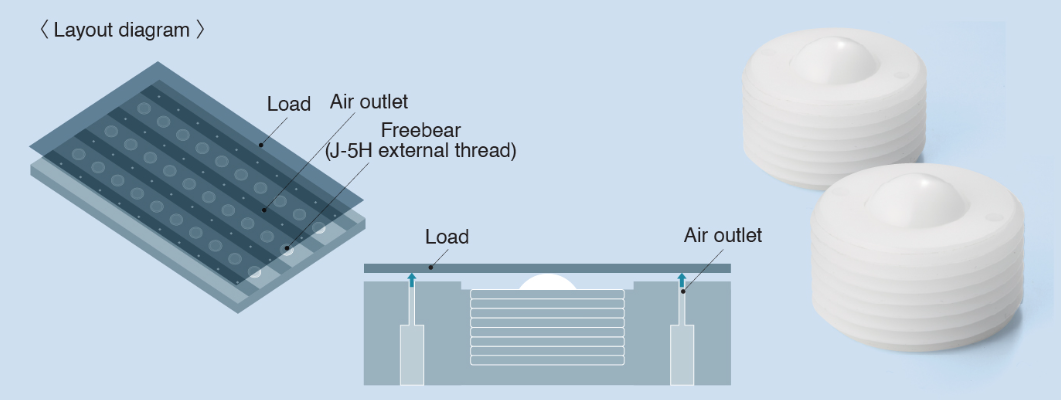

J-5H external thread

- Suitable for the conditions that there is a restriction on the mounting location or a need for saving space.

- In addition, it can achieve more stable conveyance in combination with a pneumatic carrying device.

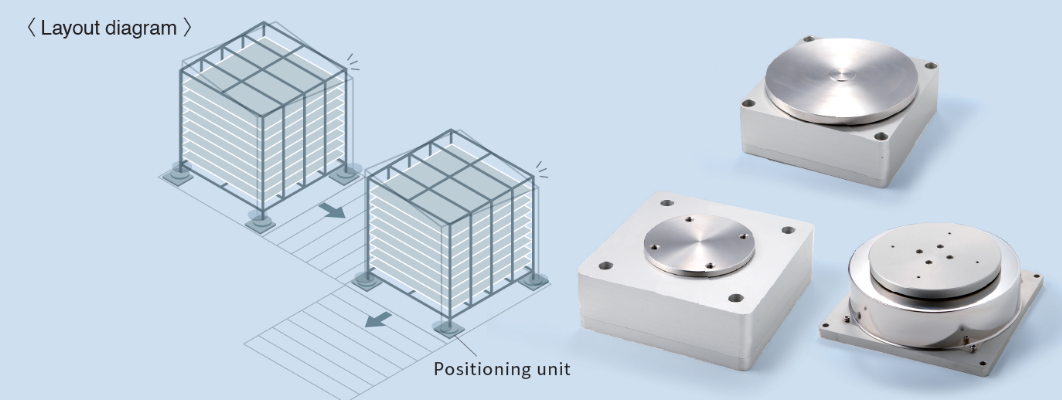

Positioning unit

- A floating unit that can position the transfer cassette for the glass substrate of liquid crystal or solar panels at 360 degrees.

- It can be used to design and manufacture units corresponding to G7~G10.

- By using the freebear and the compression spring in the center, the origin return accuracy is improved regardless of the change in shape of the spring. In addition, the cleanliness is increased with no unevenness in the appearance.

- It is also possible to provide an optional mechanism for adjusting the speed of the origin return of the operating part.

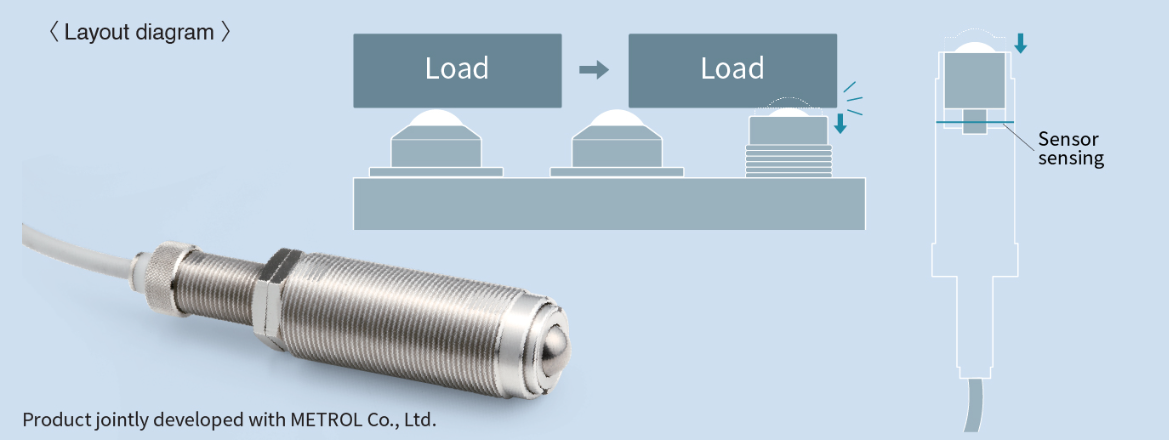

Freebear with sensors /CR

- A Sensor for detecting the passage of the workpiece is used in the freebear.

- It is helpful for the automation and labor saving of a conveying line.

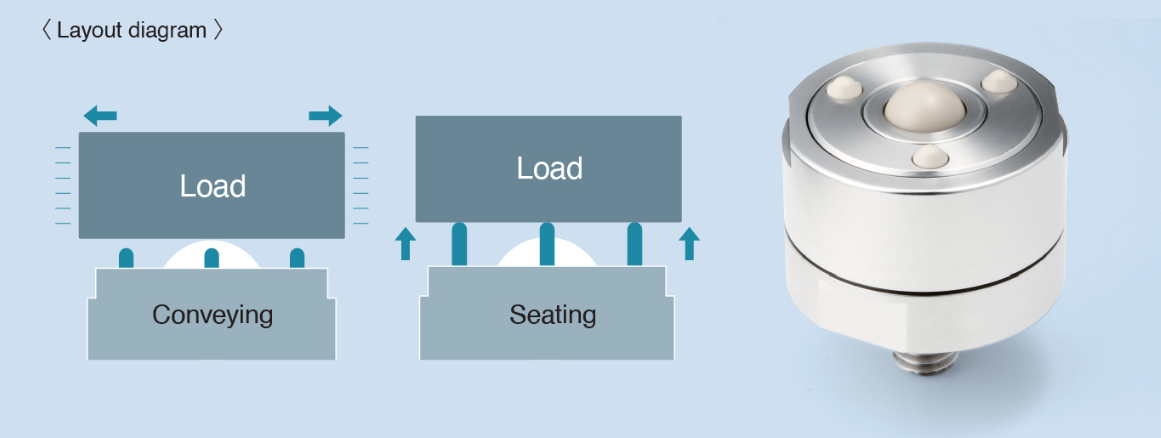

Freebear with pin 3/8″, 5/8″

- The pin floats upward by the air to fix and hold the workpiece.

- It is suitable for positioning of workpieces on a conveying line.

Related Products

-

Freebear Corporation J-○H Series Clean Room

-

Freebear Corporation AFU 3843D Series Pneumatically Actuated Freebear Unit

-

Freebear Corporation AFU 5036M 4P Pneumatically Actuated Freebear Unit

-

Freebear Corporation AFU 5050 Series Pneumatically Actuated Freebear Unit

-

Freebear Corporation AFU 2743W Air Die Lifter For Press Machines

-

Freebear Corporation D Type Bolt Freebear