Fukuda Seiko, Japan

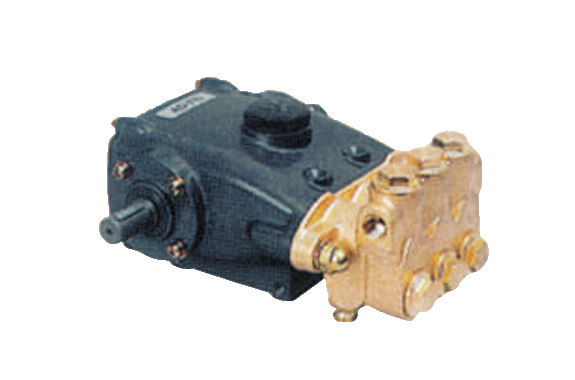

Fukuda AD-711 (S) Industrial High-Pressure Pump

Made in Japan

Manufacturer: Fukuda Seiko

Model: AD-711 (S)

Industrial high-pressure pumps. Suitable for special applications.

Use

- Water, hot water, coolant, etc. are injected at high pressure and used for cleaning and as a high-pressure coolant pump.

Features

- Long service life due to the use of ceramic plungers

- Double seal mechanism prevents water leakage

- Excellent pressure resistance performance

- Fully centering mechanism allows direct connection to engines and motors

- Low noise level

- Adoption of a special mechanism to stop chattering (pressure control valve)

STAINLESS STEEL MINI ACCUMULATOR

Stainless Steel Mini Accumulator Tokupilator

The accumulator functions to mitigate flow and pressure fluctuations within fluid circuits, reducing pulsations and shocks.

Features

- Compact and lightweight.

- Made from stainless steel, offering excellent chemical resistance and corrosion resistance.

- Exhibits stable performance through a special manufacturing process.

Main Applications

- Pulsation absorption

- Shock absorption

- Energy storage

- Balancing function

Features of Industrial High-Pressure Pumps

1. Seal Mechanism (No Lubrication Required, No Water Leakage)

If water leaks from the high-pressure side A seal, it is stopped by the low-pressure side B seal and recirculated to the suction side, ensuring no water leaks externally.

The oil-free mechanism is a key feature.

2. Ceramic Plunger (Replaceable)

The ceramic plunger has minimal wear and is resistant to scratches, which extends the lifespan of the seals.

The ceramic is securely fixed with a complete seal and locking agent, ensuring perfect alignment.

3. Seal (Long Lifespan & Easy Replacement)

The sealing section uses top-quality *T, N, B synthetic packings.

The backup system ensures the packings function effectively against high pressure.

4. Direct Drive (Easy Alignment)

The AD and D models can be directly connected to an engine or motor for use.

While designed for high-speed operation, they can also be used with pulley reduction.

Pumps for Specialized Applications

Our high-pressure pumps feature ceramic plungers for long service life. Additionally, we manufacture the following types of pumps:

High-Pressure Pumps for Ultrapure Water:

All liquid-contacting parts are made from SUS materials, and the seal sections use special materials.

Stainless Steel High-Pressure Pumps:

All liquid-contacting parts are made from SUS materials.

Seal Materials for Liquid-Contacting Parts:

NBR is standard. Options include fluoro rubber, PTFE, and high-molecular polyethylene, allowing compatibility with various liquids.

Caution

When using the pump, always fill the crank chamber with oil before operation.

Use either Engine Oil SAE 10W-30 or Industrial Lubricating Oil ISO VG100–150 Grade.

Hydraulic fluids are not suitable for use.

Reference: Pump Power Requirement Calculation Method

The power required for the pump is determined by the pump’s pressure and water intake.

It can be calculated using the formula below.

Please use this for motor selection.

HIGH-PRESSURE PUMP

For cleaning, spraying, pressure transfer, and more.

General-purpose cleaning machines

Compact cleaning units

Industrial high-pressure pumps

High-Pressure Plunger Pump Application Product Lineup

Cleaning

Spraying

Pressure transfer

Other applications

Specifications

| Model | Rotation Speed (min⁻¹) | Water Intake (L/min) | Pressure (MPa) | Power Requirement (kW) | Oil Volume (L) | Weight (kg) | Inlet | Outlet | Shaft Diameter (mm) | Key (mm) | Outer Dimensions (L×W×H mm) |

| AD-708 (S) | 1,800 | 7.9 | 7 | 1.1 | 0.35 | 6 | 2-Jan | 8-Mar | 18 | 5×5 | 237×231×122 |

| AD-1008 (S) | 1,800 | 7.7 | 10 | 1.6 | 0.35 | 6 | 2-Jan | 8-Mar | 18 | 5×5 | 237×231×147 |

| AD-711 (S) | 1,800 | 11.2 | 7 | 1.6 | 0.35 | 6 | 2-Jan | 8-Mar | 18 | 5×5 | 237×231×122 |

| AD-720 (S) | 1,800 | 19.3 | 7 | 2.8 | 0.63 | 9 | 2-Jan | 8-Mar | 20 | 5×5 | 308×256×138 |

| AD-1015 (S) | 1,800 | 15.6 | 10 | 3.3 | 0.63 | 9 | 2-Jan | 8-Mar | 20 | 5×5 | 308×256×138 |

| AD-740 (S) | 1,800 | 42.6 | 7 | 6.2 | 1.1 | 20 | 1 | 4-Mar | 25 | 7×7 | 366×269×160 |

| AD-1030 (S) | 1,800 | 32 | 10 | 6.7 | 1.1 | 20 | 1 | 4-Mar | 25 | 7×7 | 366×269×160 |

| D-2111 | 1,800 | 10.6 | 20 | 4.5 | 0.6 | 13.2 | 2-Jan | 8-Mar | 20 | 6×6 | 315×260×172 |

| D-2114 | 1,800 | 13.7 | 20 | 5.7 | 0.6 | 13.2 | 2-Jan | 8-Mar | 20 | 6×6 | 315×260×172 |

| D-2116 | 1,800 | 16 | 20 | 7 | 0.6 | 13.2 | 2-Jan | 8-Mar | 20 | 6×6 | 315×260×172 |

| D-2120 | 1,800 | 20 | 20 | 8.5 | 0.6 | 13.2 | 2-Jan | 8-Mar | 20 | 6×6 | 315×260×172 |

| D-3511 | 1,800 | 11 | 35 | 8.2 | 0.6 | 13.4 | 8-Mar | 8-Mar | 20 | 6×6 | 315×260×172 |

High-Pressure Plunger Pump Application Product Lineup

Machine Tools

Parts Washing Machine

High-Pressure Pump Unit (Two-Story)

High-Pressure Coolant System

Micro Hole Electrical Discharge Machine

Kouei is Distributor/Agent of Fukuda.

Other items of Fukuda

Request the quotation for Fukuda.

Related Products

-

Ross Asia Pneumatic pressure switch Electrical output

-

Kyowa Type T Automatic Valves

-

Chiyoda Tsusho TEE’S SLEEVE CONNECTOR

-

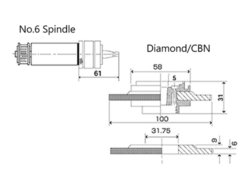

UHT Corporation Borazon Grinding Wheels for Spindle No.6 #200 With Flange

-

Kakuta No.42P-2S Hold Down Clamp

-

Kimoto Couplings & Bodies Slope and furnace spraying construction materials