Fukuda Seiko, Japan

Fukuda EA090A Series Brushless DC Moto

Made in Japan

Manufacturer: Fukuda Seiko

Model: EA090A Series: EA090A-1/ EA090A-2/ EA090A-3

Features

The Fukuda EA090A Series Brushless DC Motor delivers high continuous torque in a compact NEMA 34 frame, specifically engineered for precision motion control applications. Designed for reliability, this motor features an IP-65 protection rating, effectively resisting dust and low-pressure water jets—ideal for harsh industrial environments. Moreover, the EA090A–3 variant, as part of the broader EA090A lineup, offers one of four motor lengths, supporting continuous torque outputs from 1.8 to 4.6 Nm, perfectly suited for high-load, closed-loop systems. Additionally, the brushless design improves durability and energy efficiency, while the sealed housing ensures long-term, stable operation under demanding conditions.

Benefits

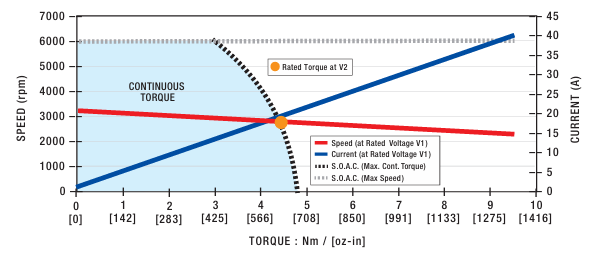

Speeds up to 6,000 RPM possible

DC bus voltage up to 325 VDC

NEMA 34 package

Five standard windings

4 pole rare earth design

Optional Assemblies

Encoders: Q, C Types

Programmable Drive: BGE6060A

Motor Characteristics

| Motor Data | Units | EA090A-1 | EA090A-2 | EA090A-3 |

|---|---|---|---|---|

| Max DC Terminal Voltage (VT) | V | 325 | ||

| Max Speed (Mechanical) (ωMAX) | rpm | 6000 | ||

| Continuous Stall Torque (TCS) | Nm / lb-in | 1.8 / 260 | 3.4 / 480 | 4.6 / 650 |

| Peak Torque (Maximum) (Tpk) | Nm / lb-in | 9.5 / 1300 | 18 / 2500 | 25 / 3500 |

| Coulomb Friction Torque (Tf) | Nm / oz-in | 0.041 / 5.8 | 0.055 / 7.8 | 0.069 / 9.8 |

| Viscous Damping Factor (D) | Nm/(rad/s) / oz-in/krpm | 2.7E-05 / 0.40 | 6.7E-05 / 1.0 | 2.0E-04 / 2.9 |

| Thermal Time Constant (τth) | min | 20 | 25 | 30 |

| Thermal Resistance (Rth) | °C/W | 1.1 | 0.89 | 0.78 |

| Max. Winding Temperature (θMAX) | °C | 155 | ||

| Rotor Inertia (Jr) | kg·m² / lb-in·s² | 1.1E-04 / 0.016 | 2.0E-04 / 0.029 | 2.9E-04 / 0.042 |

| Motor Weight (Wm) | g / oz | 3600 / 130 | 5000 / 180 | 6500 / 230 |

We recorded all values at maximum winding temperature with a 25°C ambient and no heatsink. To operate a brush motor with the PBL4850E, you must use an encoder.

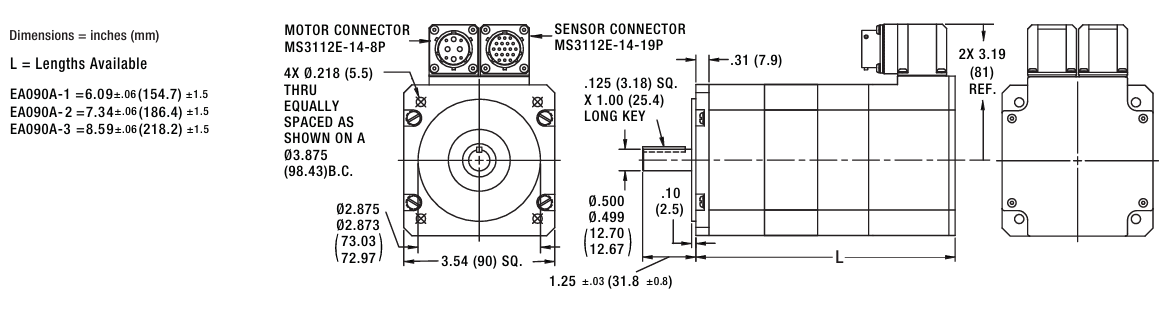

Dimensional Drawings: EA090A-1/ EA090A-2/ EA090A-3

| Motor Data | Units | |||||

| Rated Voltage V1 Vr | V | 305 | 152 | 305 | 305 | 305 |

| Rated Torque1 • Tr | Nm | 2.8 | 2.9 | 2.9 | 3.6 | 4.1 |

| oz-in | 390 | 420 | 420 | 510 | 580 | |

| Rated Speed1 cor | rpm | 6000 | 5980 | 6000 | 4880 | 3790 |

| Rated Current1 Ir | A | 16 | 13 | 9.8 | 6.8 | 6.1 |

| Rated Power1 Pr | W | 1700 | 1800 | 1800 | 1900 | 1600 |

| No Load Speed coni | rpm | 6000 | 5980 | 6000 | 5000 | 4000 |

| No Load Current ini | A | 1 | 0.8 | 0.58 | 0.3 | 0.21 |

| Rated Voltage V2 Vr | V | 152 | 76 | 152 | 152 | 170 |

| Rated Torque1 • Tr | Nm | 2.8 | 4.4 | 4 | 4.6 | 4.7 |

| oz-in | 400 | 620 | 560 | 650 | 660 | |

| Rated Speed1 cor | rpm | 6000 | 2730 | 4150 | 2200 | 1920 |

| Rated Current1 Ir | A | 16 | 19 | 13 | 8.4 | 6.8 |

| Rated Power1 Pr | W | 1800 | 1300 | 1700 | 1100 | 940 |

| No Load Speed coni | rpm | 6000 | 2990 | 4330 | 2490 | 2230 |

| No Load Current Ini | A | 1 | 0.54 | 0.48 | 0.21 | 0.16 |

| Motor Constant Km | NmA/W | 0.43 | 0.45 | 0.45 | 0.45 | 0.45 |

| oz-inA/W | 61 | 64 | 64 | 64 | 63 | |

| Torque Constant Ky | Nm/A | 0.194 | 0.242 | 0.334 | 0.581 | 0.726 |

| oz-in/A | 27.4 | 34.3 | 47.3 | 82.2 | 103 | |

| Voltage Constant Ke | V/(rad/s) | 0.194 | 0.242 | 0.334 | 0.581 | 0.726 |

| V/krpm | 20.3 | 25.3 | 35 | 60.8 | 76 | |

| Terminal Resistance Rmt | Q | 0.2 | 0.29 | 0.55 | 1.66 | 2.64 |

| Inductance L | mH | 0.71 | 1.1 | 2.2 | 6.4 | 10 |

| Peak Current Ipk | A | 130 | 110 | 80 | 45 | 36 |

| Electrical Time | ms | 3.6 | 3.8 | 4 | 3.9 | 3.8 |

| Constant Te | ||||||

| Mechanical Time | ms | 1.6 | 1.5 | 1.4 | 1.4 | 1.5 |

| Constant Tm | ||||||

We use the V1 and V2 ratings to illustrate how the motor winding performs under different applied voltages. To ensure precise motor selection, you must refer to the voltage constant (V/krpm) as a key specification. Moreover, always pair this value with the correct motor part number to match application requirements. For instance, when selecting a motor like DC030C-1, consider its 3.31 V/krpm voltage constant to determine its suitability for your drive voltage and speed range. This method ensures optimized winding performance and reliable operation across varied system configurations.

1Recorded at maximum winding temperature at 25°C ambient and without heatsink.

Related Products

-

NISSAN TANAKA PIPEAUTO Automatic Pipe Welding Machine

-

SAKUSAKU CCGT120404-UG Turning Insert 80° Rhombic/7° Positive

-

Tohnichi R-CM Torque Verification Equipment

-

Nitta 1100 Series Thermoplastic Hose

-

Watanabe WPM-1-11 Digital panel meter for DC voltage/current (single display, 48 x 96) – DC meter

-

Tosei Sharyo T-N Series Caster