Manufacturer: Fukudaco

Model: HFGS

Overview

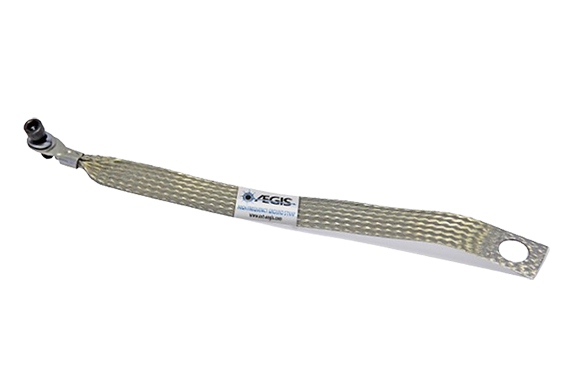

Proper high-frequency grounding in inverter motors is essential to prevent potential differences between equipment housings. The Aegis® High-Frequency Grounding Strap completes the path from the motor to the system ground, ensuring reliable performance.

Applications

- Reduces voltage differences between equipment housings.

- Excels in handling the skin effect of high-frequency currents.

Features

- Available in custom lengths (in approximately 150mm increments).

Aegis® Rings and Aegis® HFGS (High-Frequency Grounding Strap)

Aegis® Rings protect motor bearings and prevent bearing failures like fluting. Meanwhile, the Aegis® HFGS (High-Frequency Grounding Strap) ensures a reliable path to system ground.

In such cases, you need an effective high-frequency grounding system to equalize the potential between equipment frames and prevent grounding loops between the motor and connected equipment.

High-frequency braided straps (Aegis® High-Frequency Grounding Straps) are highly effective for this purpose and are recommended by leading motor and drive manufacturers. These straps provide an extremely low-impedance path from the motor frame to the ground, countering the high-frequency currents generated by inverters.

Aegis® Rings provide a safe path for currents flowing through motor bearings, and together with the Aegis® High-Frequency Grounding Strap, they complete the grounding path from the motor to the system ground. This combination ensures optimal protection and performance.

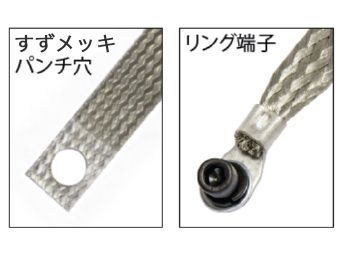

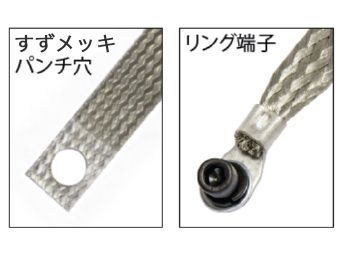

The high-frequency grounding strap is designed with one end featuring a tin-plated punched hole for securing an 8mm [5/16″] bolt, based on NEMA/IEC frame sizes, and the other end as a ring terminal.

Standard lengths are 305mm [12″] and 610mm [24″]. For longer lengths, we provide increments of 150mm. Additionally, we offer universal straps with ring terminals on both ends.

You can also request longer straps and other terminal types to meet your specific needs.

Standard Product Model Numbers

12″ Series (Approximately 300mm Length)

24″ series (length approx. 600mm)

| Model number | End A | End B | IEC frame number (reference) |

|---|

| HFGS-T0410-R0312-24 | Round hole processing (Φ10mm) | Crimp terminal processing (8mm) | 80M / 90S / 90L |

| HFGS-T0660-R0312-24 | Round hole processing (Φ17mm) | Crimp terminal processing (8mm) | 100S / 100L / 112S / 112L / 132S / 132M / 160S / 160L / 180S / 180M / 180L |

| HFGS-T0940-R0312-24 | Round hole processing (Φ24mm) | Crimp terminal processing (8mm) | 200S / 200M / 200L / 225S / 225M /250S / 250M / 280S / 280M |

| HFGS-R0312-R0312-24 | Crimp terminal processing (8mm) | Crimp terminal processing (8mm) | |

*If longer lengths are required, we can provide them upon request in increments of 6″ (approx. 150 mm) up to 24″ (approx. 600 mm).