Biax, Germany

Biax Air Spindle For Deburring Robot

Manufacturer: Biax

Overview

A manufacturer of high-precision and durable air tools for many years. Leveraging its accumulated technology, the company has developed an air-powered floating mechanism for deburring, which has been widely adopted for deburring automation around the world.

Applications

Automation of deburring by robots (secondary burrs after cutting, casting burrs, etc.)

Features

Floating system (PAT.P) capable of handling various burrs

Air motor ensures no heat generation even during prolonged use

Air motor eliminates electrical issues such as cable breakage

High-precision spindle rotation with micron-level accuracy

High durability

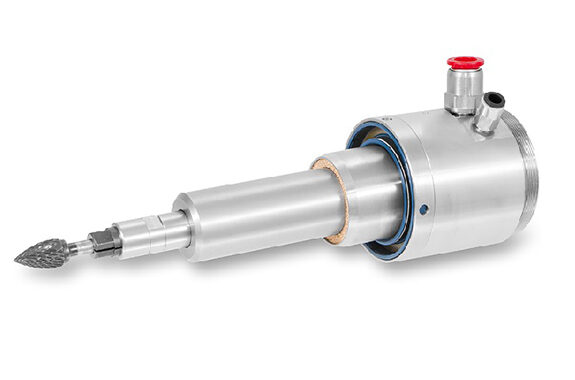

Air spindle with floating holder

High precision, high rigidity, floating force adjustable

The air spindle developed by BIAX (Germany) features high precision and high rigidity, allowing you to select rotational speeds of 12,000, 22,000, 30,000, or 40,000 (min-1) depending on the cutting tool used. Additionally, the floating force can be adjusted over a wide range up to a maximum of 70N by regulating the air pressure, making it suitable for handling both small burrs after cutting and large burrs such as casting burrs. Its compact and lightweight design makes it possible to mount it on small multi-axis robots, such as those with a payload capacity of 5kg.

Specification

| Model | Rotational Speed | Maximum output | Maximum torque | Compatible collet diameter | Maximum blade diameter | Air consumption | weight |

|---|---|---|---|---|---|---|---|

| F12NTC | 12,000min -1 | 400W | 0.80Nm | 6, 8, 10mm | 15mm | 790ℓ/min | 2,350g |

| F22NTC | 22,000min -1 | 310W | 0.51Nm | 3, 6, 8mm | 12mm | 500ℓ/min | 1,900g |

| F30NTC | 30,000min -1 | 240W | 0.24Nm | 3, 6, 8mm | 10mm | 400ℓ/min | 1,600g |

| F40NTC | 40,000min -1 | 240W | 0.24Nm | 3, 6, 8mm | 8mm | 400ℓ/min | 1,600g |

The rotation speed, maximum output, maximum torque, and air consumption are values at 0.6 MPa.

All collets come with a 6 mm collet as standard.

Robot connection adapter

We have a dedicated adapter (M60 x 1 female thread) for easily connecting the floating holder to a robot. It is made of aluminum and can be used simply by drilling a hole that matches the flange surface of the robot.

(Compatible models: F12NTC, F22NTC, F30NTC, F40NTC)

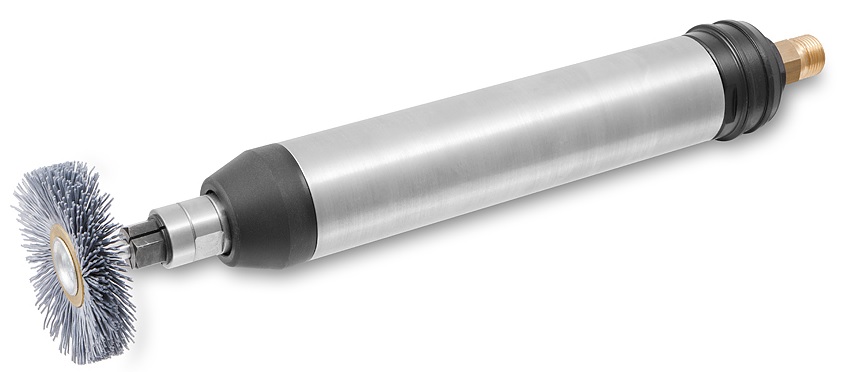

High-power, low-speed air spindle

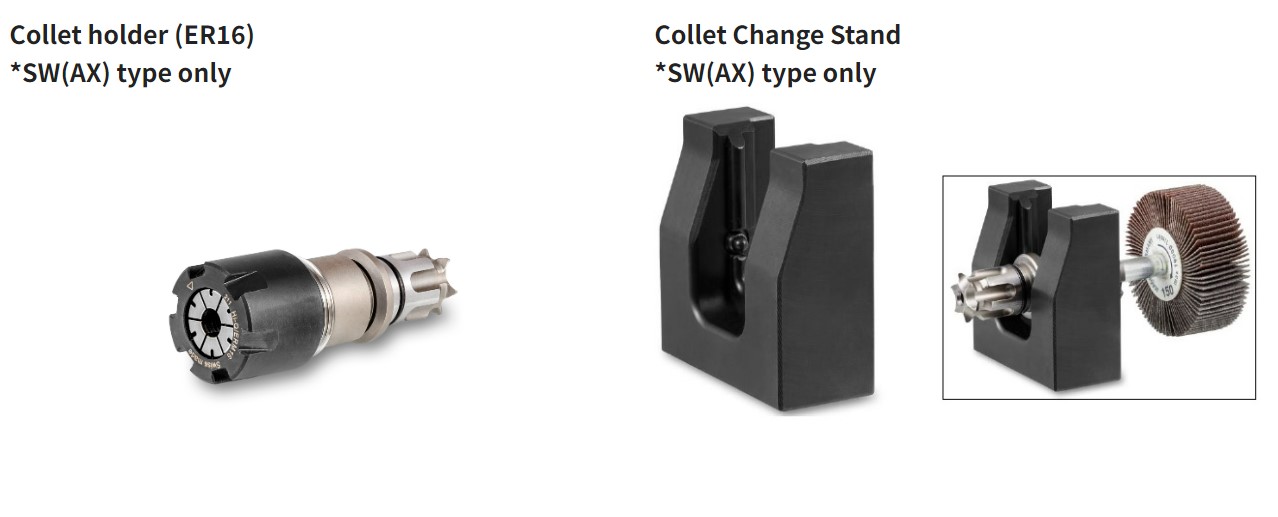

This is a robot spindle that is effective when using cutting tools that require large torque at low rotation speeds, such as wire brushes. In addition to the standard collet type, from 2021 there will also be a new product, the SW type with a collet specification that can be replaced with one touch, and the SW AX type with an additional mechanism for floating in the axial direction. With the SW and SW AX types, by using a dedicated collet holder and collet change stand, cutting tools can be automatically replaced by a robot, etc. (Collet ATC compatible).

Specification

| Model | Rotational Speed | Maximum output | Maximum torque | Compatible collet diameter | Maximum brush diameter | Air consumption | weight |

|---|---|---|---|---|---|---|---|

・R4102 ・R4102 SW ・R4102 SW AX | 1,700min -1 | 750W | 6.0Nm | 6, 8, 10mm | 100mm | 850ℓ/min | 1,400g |

・R4105 ・R4105 SW ・R4105 SW AX | 5,000min -1 | 750W | 2.5Nm | 6, 8, 10mm | 80mm | 850ℓ/min | 1,400g |

| Model | Rotational Speed | Maximum output | Maximum torque | Compatible collet diameter | Maximum blade diameter (maximum grindstone diameter) | Air consumption | weight |

|---|---|---|---|---|---|---|---|

・R4112 ・R4112 SW | 12,000min -1 | 400W | 0.8Nm | 6, 8, 10mm | 24mm (15mm) | 790ℓ/min | 750g |

The rotation speed, maximum output, maximum torque, and air consumption are values at 0.6 MPa.

All collets come with a 6 mm collet as standard.

R4105 (standard)

R4105 SW (One-touch collet type)

R4105 SW AX (One-touch collet type)

*With the axial floating mechanism