Fukudaco, Japan

Fukudaco Automated Transport Components

Manufacturer: Fukudaco

Overview

Significantly extended lifespan and wear resistance. Reduced air consumption and noise levels.

Founded in 1982 as a hydraulic robot manufacturer, the company leveraged its experience and technology to shift its focus to automation in 1992. Today, it is the world’s leading manufacturer of press transfer units for automotive doors and bodies, with a strong track record of adoption by various automobile manufacturers.

Applications

Automotive door panels, body press transfer, and sheet metal transfer

Features

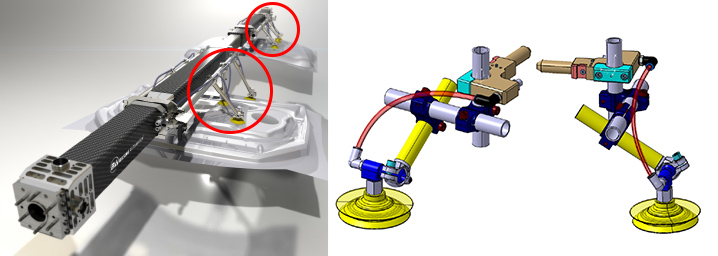

CFRP Crossbar Beam

Utilizes CFRP with damping materials incorporated into the components, enabling high-speed automatic transfer.

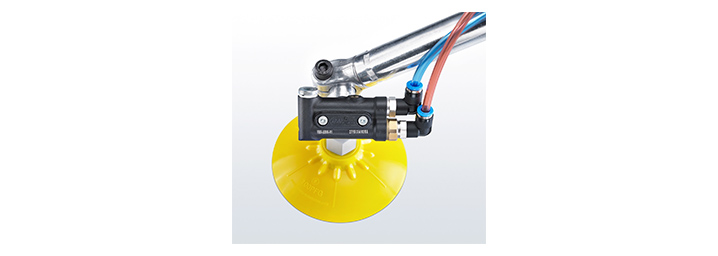

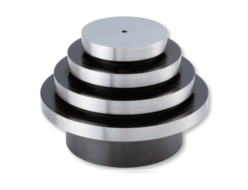

Vacuum Pad

Made of thermoplastic elastomer, providing long lifespan and high wear resistance.

Quick responsiveness to the suctioned workpiece.

Silicone-free, environmentally friendly, and recyclable.

Ejector

Significantly reduces air consumption.

Improves the speed of vacuum on/off switching.

No need for a silencer, making it very quiet.

Components for Automatic Transfer Systems

Vacuum Pads, Ejectors

The latest servo press machines and automation technologies have improved production processes in press shops. Faster operation speeds require vacuum pads that not only offer high holding power and durability but also maintain quick responsiveness to the workpiece.

Benefits of Vacuum Pads

Free deformation and very high suction power

Excellent adaptability to component shapes

Does not damage the workpiece surface due to integrated molding

Retains the workpiece even during emergency stops

High wear resistance and durability

Suitable for use on aluminum, steel, and plastic surfaces

Recyclable

Related Products

-

Niigata Seiki OD MODEL SPECIAL SHAPE – MULTIPLE-STEP GAUGE

-

NPK Hoists

-

Eagle Clamp VRS-F Type Starpoint Eye Bolt

-

Nippon Daiya Valve Fluorocarbon Resin Corrosion Resistant Valves Of Clamp Connections/Flange Connections

-

Kurimoto MCD- 80, MCD- 100, MCD- 160, MCD- 250, MCD- 300 Three-shaft Type Indirect Heating Dryer

-

Kurimoto TES-60 Forging Press