Fukudaco, Japan

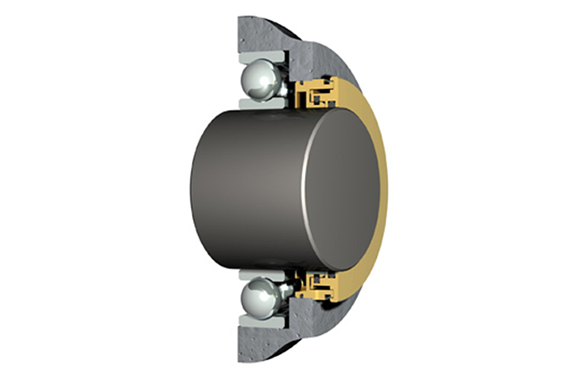

Fukudaco Bearing Isolator (Labyrinth Seal)

Manufacturer: Fukudaco

Overview

Designed for machinery in petrochemical plants, paper mills, steel mills, and more, such as steam turbines, pumps, motors, gearboxes, pillow blocks, and mixers. Each labyrinth seal is custom-designed for specific equipment. With IP66-equivalent sealing performance, it prevents water and dust from entering the bearings, protecting them throughout their expected lifespan.

Applications

- Pumps

- Motors

- Gearboxes

- Pillow blocks

- Paper mill rolls

- Powder handling equipment

Features

- Forms a complex labyrinth structure with high sealing performance through the combination of rotor and stator.

- Prevents air movement even when stationary, thanks to the VBX® ring.

- The non-contact design eliminates friction, wear, and heat generation, ensuring a long lifespan.

Further evolved bearing isolator “VB45 series”

The VB45 series is Inpro/Seal’s latest series of bearing isolators. The chamber angle of the conventional VBX® ring (vapor O-ring) is inclined at 45 degrees, making the seal thinner while maintaining high sealing performance. It has already been adopted in many production facilities both in Japan and overseas.

VB45-S ™ (16mm thin with IP66 equivalent sealing performance)

VB45-S ™ maintains the same high sealing performance as before with a thickness of about 16mm. In addition, the D groove for oil bath lubrication has been enlarged, and the sealing performance against oil leakage has been strengthened.

- Provides high sealing performance equivalent to IP66 for a long period of time

- No sealing torque due to non-contact labyrinth seal

- 45-degree inclined VB45 chamber provides a 16mm seal thickness

- The D groove (lubricant capture area) has been enlarged to improve sealing against oil leaks.

- Maintenance-free and long life

VB45-U ™ (for large-axis travel and various conditions)

The VB45-U ™ has a standardized design that supports a variety of lubrication methods, including oil bath lubrication, grease lubrication, and oil mist lubrication, and can also be used on machines with large-axis travel.

- Provides high sealing performance equivalent to IP66 for a long period of time

- No sealing torque due to non-contact labyrinth seal

- 45-degree inclined VB45 chamber minimizes seal thickness

- Universal lubrication (oil bath, oil mist, and grease compatible)

- Maintenance-free and long life

- Integrated rotor accommodates greater axial travel

Table 1 VB45-S ™ and VB45-U ™

| VB45-S ™ | VB45-U ™ | |

|---|---|---|

| Minimum: [15.88mm] | Standard Seal Thickness | Minimum: [17.78mm] |

| Minimum: [8.89mm] | Standard assembly width | Minimum: [8.89mm] |

| Minimum: [6.99mm] | Standard protrusion dimensions | Minimum: [8.89mm] |

| Minimum: Shaft diameter + [19.05mm] | Standard Housing Inner Diameter | Minimum: Shaft diameter + [22.23mm] |

| Seals: Bearing bronze O-rings: NBR and FKM | Standard Materials | Seals: Bearing bronze O-rings: FKM and PTFE |

| Maximum axial movement: [0.13mm] Maximum radial movement: [0.25mm] | Allowable shaft movement | Maximum axial movement: [6.35mm] Maximum radial movement: [0.25mm] |

| Circumferential speed: 60 (m/s) | Permitted Speed | Circumferential speed: 60 (m/s) |

As this product is manufactured in inches, the metric dimensions [ ] are for reference only.

Related Products

-

Tosei Sharyo EJ Series Gold Caster

-

HANKOKU SBGM-2WU Motor Siren (Three Phase)

-

Obishi Keiki Seisakusho Granite Parallel Bar

-

Kanetec KETV-3060F Electromagnetic Chuck With Vacuum Chuck Function

-

Chiyoda Seiki MSCP-15-B Semi-automatic Switching Gas Supply Device Stand Set (Standard flow rate: 15m3/h / Air)

-

Seiwa E04RC161010 Ferrite Core Non-split Ring Cores RC and RM and RMX Types EMC Products