Fukudaco, Japan

Fukudaco Belt-Driven Grinding Spindle

Manufacturer: Fukudaco

Overview

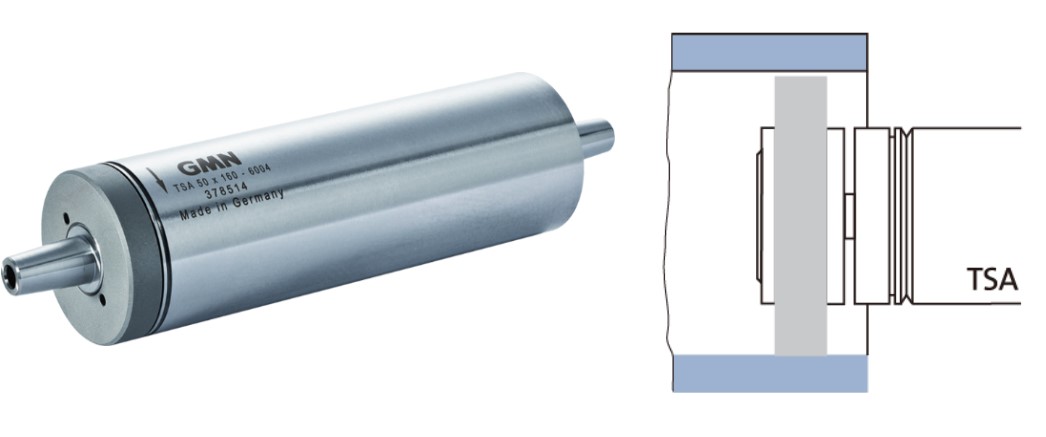

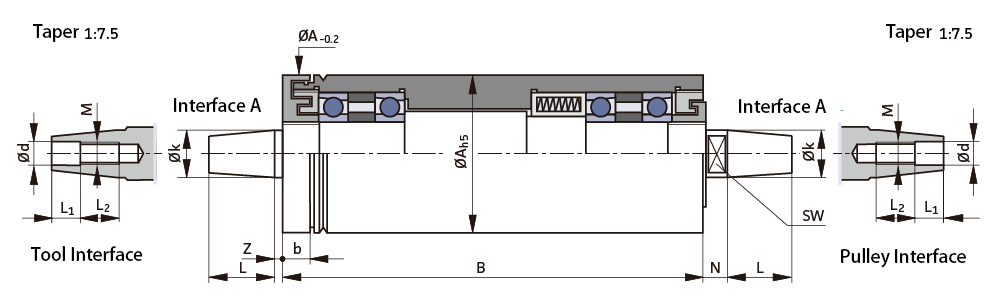

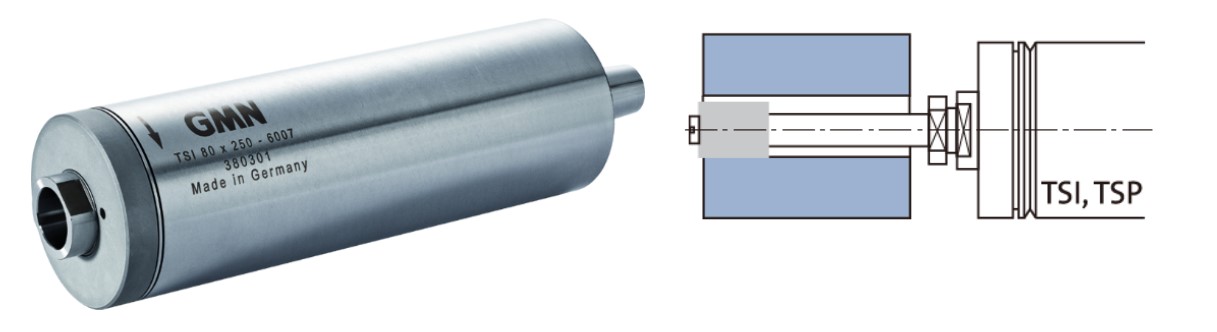

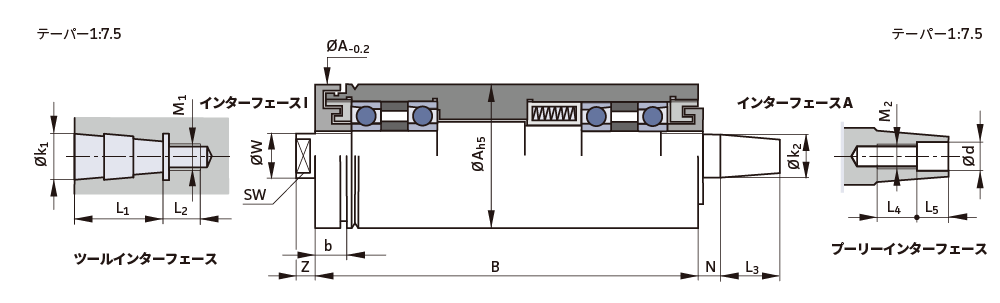

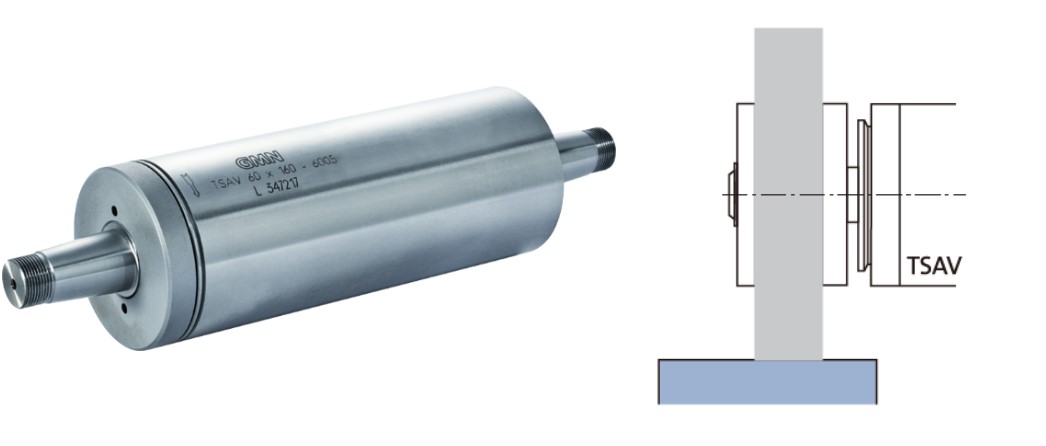

GMN uses belt-driven spindles for high-speed grinding operations. For small-diameter internal grinding, they recommend the TSI/TSP series. The TSA series is suitable for internal grinding of holes larger than the spindle body diameter. For external grinding or surface grinding with high processing loads, the TSAV series is recommended. Additionally, the TSL series is available for deep-hole internal grinding.

Applications

- Internal grinding

- External grinding

- Surface grinding

Features

Uses in-house precision bearings

Body diameter: φ20–200 mm

Maximum rotation speed: 80,000 min-1

Grease lubrication specification

Customizable with a variety of options

Maintenance supported by the only GMN-certified factory in Japan

Related Products

-

UHT Corporation Hose Joint For Air Mirco Grinder

-

Hammer Caster 220S Stainless Steel Corner Caster

-

Royal Master 1101SW Hydraulic Pump Unit – Hydraulic Puncher

-

Chiyoda Seiki Line Burner For Preheating And Strain Relief Of Steel Plate

-

TEIKOKU Screw Spikes For Railway

-

TONE 4TX-T Torx Socket (Heavy Duty)