Fukudaco, Japan

Fukudaco High-Performance Air Gear Motor Spindle and Floating Holder

Manufacturer: Fukudaco

Overview

Spindle & Holder for Deburring Robots Using the Latest Technology

Application

Automation of deburring by robots

Features

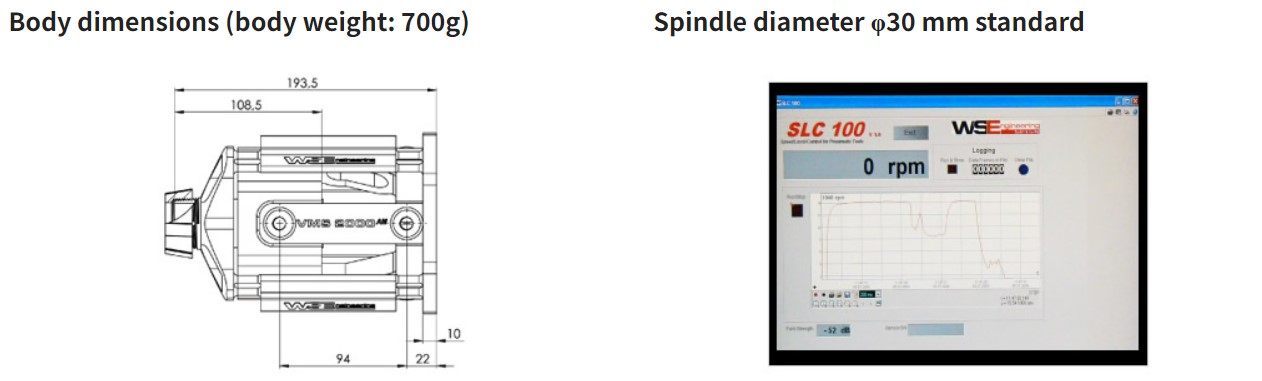

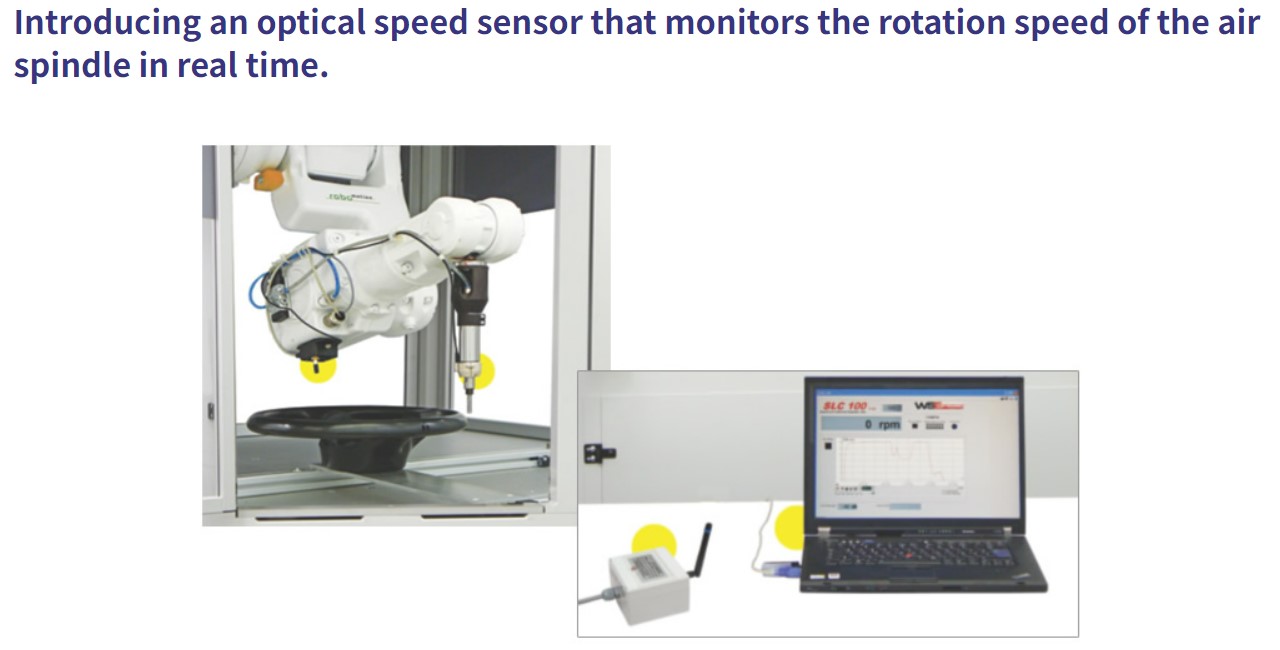

Spindle

Strong load resistance with persistent torque using an air gear motor

Can be used without lubrication (suitable for resin processing, etc.)

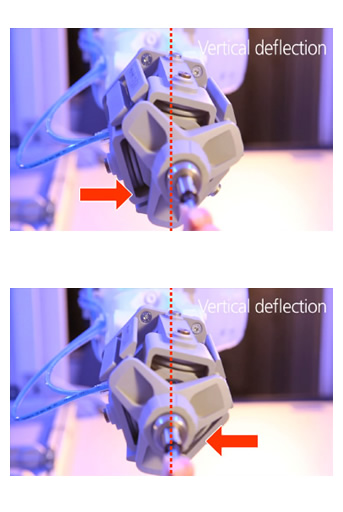

Holder

Lightweight due to resin construction

Compatible with spindles from other manufacturers

Air Gear Motor Spindle

High output and high torque without oil

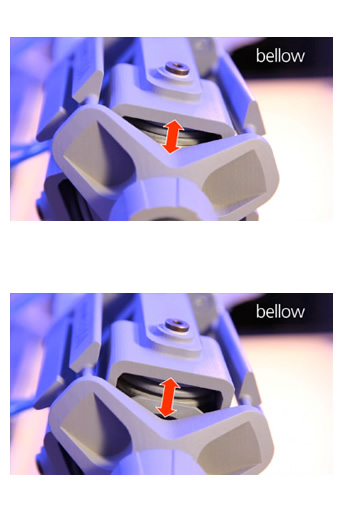

RS30ZM Series: Spindle body diameter ϕ30 mm

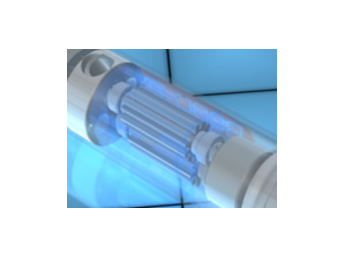

The Air Gear Motor Spindle developed by WSE (Germany) is the world’s first to use a gear motor in industrial spindles. It achieves unparalleled high torque and high output with minimal air loss. Furthermore, it is completely oil-free with no lubrication required, thanks to the use of special resin gears.

Features

High torque, high output

Oil-free, high-durability

Air-powered yet continuous operation

Capable of forward and reverse rotation

Newly Developed WSE Air Gear Motor

The driving air enters through the inlet and flows to the opposite side outlet along the inner surfaces above and below the gear gaps. This process ensures that the gear rotates, generating persistent torque that cannot be easily stopped even with a slight pressure of 0.3 MPa air pressure. Additionally, the special resin gears provide quiet operation and oil-free performance, making it a completely new type of air motor, unlike any traditional model.

WSE Air Gear Motor Spindle

Specification

| Model | Rotational Speed | Maximum output | Maximum torque | Maximum cutting diameter | Noise | Weight |

|---|---|---|---|---|---|---|

| RS30ZM30 | 30,000min -1 | 250W | 0.27N/m | 8mm | 73dB(A) | 490g |

| RS30ZM40 | 40,000min -1 | 200W | 0.21N/m | 6mm |

Oil-free vane motor spindle

WSE (Germany) vane motor spindles are pneumatic spindles that use vanes made of special materials developed in-house and can be operated without lubrication (except for RS45LM20).

RS .. LM series: Spindle body diameter ϕ30, ϕ32, ϕ38, ϕ45 mm

*RS45LM20 is not oil-free.

Related Products

-

YOSHITAKE TSF-11AT Steam Trap/Air Trap

-

UHT Corporation CS70-4 #800 Blue Ceramic Stones

-

Tsugaru Kogyo No.2005 Versatile Single Clamp (13φ) with Hot-Dip Galvanization

-

TONE TN-30E-1, TN-30E-2 Electronic Angle Control Wrench

-

Hammer Caster 740MR Caster For Shopping Carts

-

Super Tool BST33515 / 34020 / 43728B~89055B Four Faces Jig Block T-Slot Type (14 / 16) for MC