Fukudaco, Japan

Fukudaco MiniCODER Series for Machine Tools

Manufacturer: Fukudaco

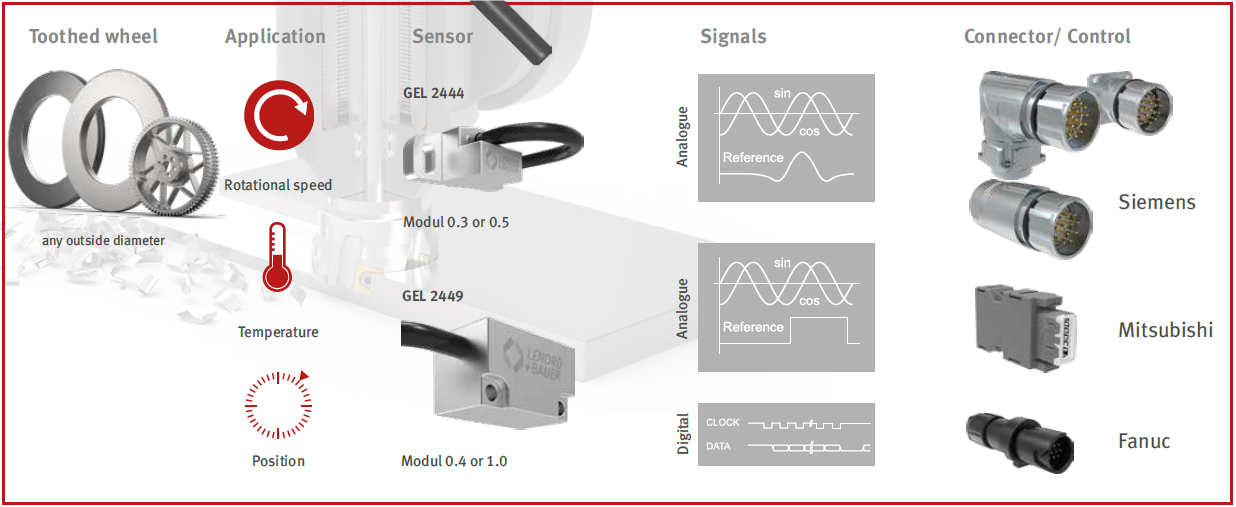

Overview

These are non-contact, high-precision, high-speed capable speed and position encoders.

Applications

- Machine tool spindle speed and position detection (ATC)

- High-frequency spindle speed detection

- Radar equipment angle detection

- Speed detection for testing equipment

Features

- Extremely compact sensor head

- Customizable target wheel (detection gear)

- Compatible with Mitsubishi CNC protocols (M800/M80/E80/C80)

- High waterproof and dustproof standards, compliant with IP68

Specification

| Sensor head dimensions H x W x D | 15.5(mm) x 37.5(mm) x 21.4(mm) (GEL2444) |

|---|---|

| Target wheel inner diameter | 8mm and up |

| module | 0.3, 0.5, 1.0 |

| Output Signal | Sine wave output signal 1Vpp / Square wave output signal TTL / Mitsubishi CNC protocol |

| Rotational Speed | Max. 100,000 min -1 possible (depending on target wheel diameter) |

| Operating temperature | -30℃~+85℃ |

| Protection rating | IP68 |

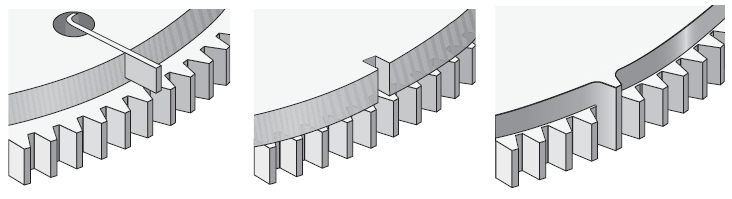

Target Wheel

The target wheel detected by the sensor head has three structural options for the reference position:

Flag – Slot – Teeth

Each structure has distinct characteristics, allowing you to choose based on your specific needs:

- Flag: Not suitable for high-speed rotation due to structural imbalance, but advantageous in terms of cost.

- Slot: Offers better balance compared to the flag type.

- Teeth: Less cost-effective but provides excellent balance due to being machined, capable of handling speeds up to 100,000 min-1.

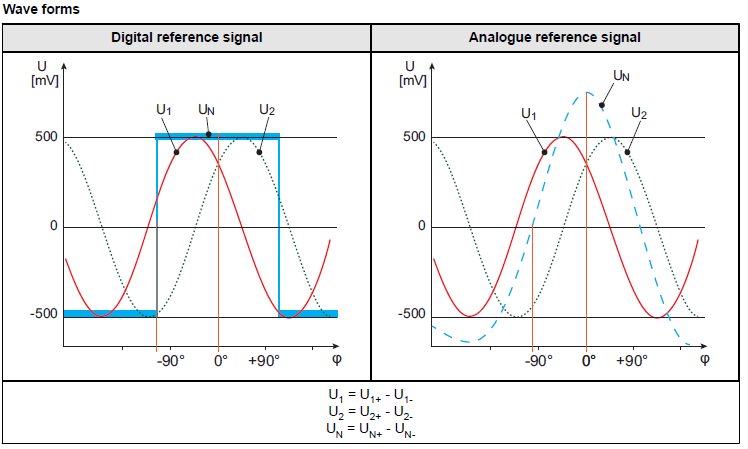

Output Signal Waveform

The output signals from the rotary encoder consist of two-phase rotation signals and one-phase reference position signal. The two types of signals output by the rotary encoder are:

- U1, U2: These signals are used for rotation control. You can choose between square wave or sine wave, depending on the specifications of the connected controller.

- UN: This signal is used for positioning control and is output once per revolution. You can choose between a flat (left diagram) or a peaked (right diagram) waveform.

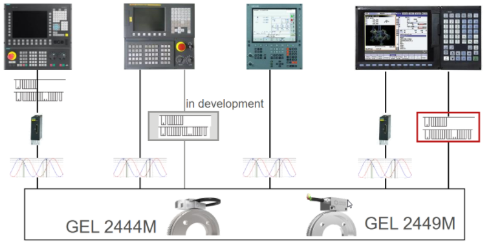

Digital Communication

We provide products compatible with various communication protocols from different manufacturers (some still under development).

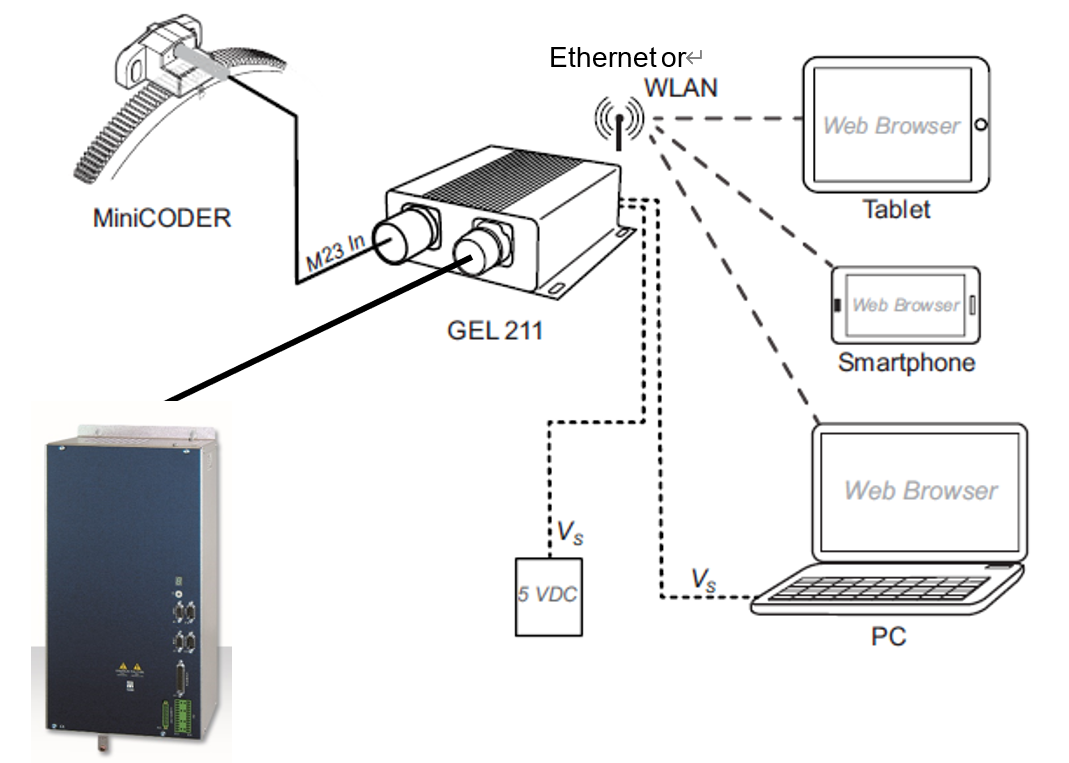

On-line Inspection Module GEL211

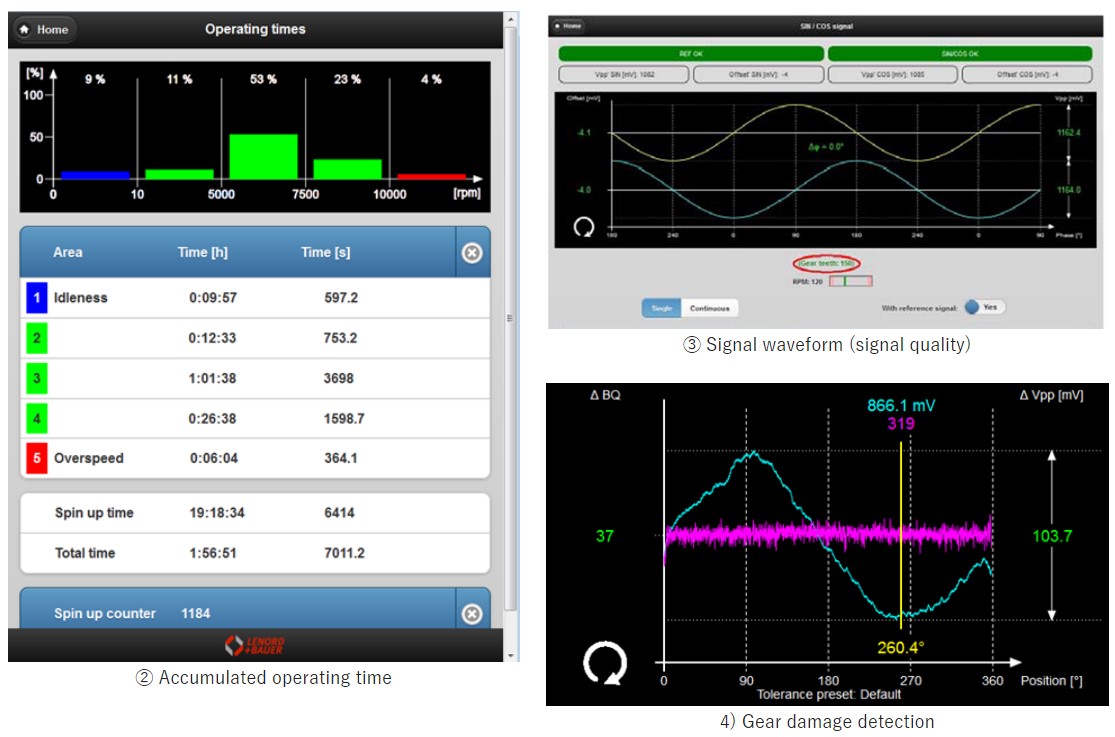

The on-line inspection module GEL211 allows for the verification and signal correction of the following items in an on-machine state.

- Operating Statistics: Determines the operational duration within various speed ranges.

- Cumulative Operating Time: Tracks the total operating time.

- Signal Waveform: Monitors signal quality.

- Gear Damage Detection: Identifies damage to gears.

- Signal Correction: Performs signal adjustments.

Signal correction and confirmation of accumulated operating time can be done from a PC, tablet, etc. Also, you can set and check from the following browsers you are already using without installing special software.

- Firefox 10+

- Safari 5.0+

- Chrome 16+

- Opera 10+

Related Products

-

Super Tool DTRH2010C/3025C/3050C/4100C/4200C/6300C Digital Torque Wrench High-specifications – Cable type

-

Watanabe A7000 Series A7□16 AC current digital panel meter

-

PRESTAR Foot Parking Series Hand Truck

-

Eagle Jack (Konno Corporation) G-60 Standard Toe Jack

-

Vessel No.70 Plastic Head Hammer (Size.1/4)

-

Sumitomo QS-110026-VE Moisture Curing Pre-grouted PC Steel Material