Fukudaco, Japan

Fukudaco Modular Clamping System

Manufacturer: Fukudaco

Overview

The drawbar system from OTT-JAKOB, which is standardly adopted by machine manufacturers worldwide, allows for the construction of optimal clamping systems by combining a wide variety of products. It offers a range of products to facilitate the ATC automatic tool change of motor spindles.

Applications

- Power drawbar systems

- General machine tools

- Machining centers

- Lathes

- Grinding machines

- Multi-tasking machines

- Manual clamps

- Various turrets

Features

- Tool interface: HSK, SK/BT shank

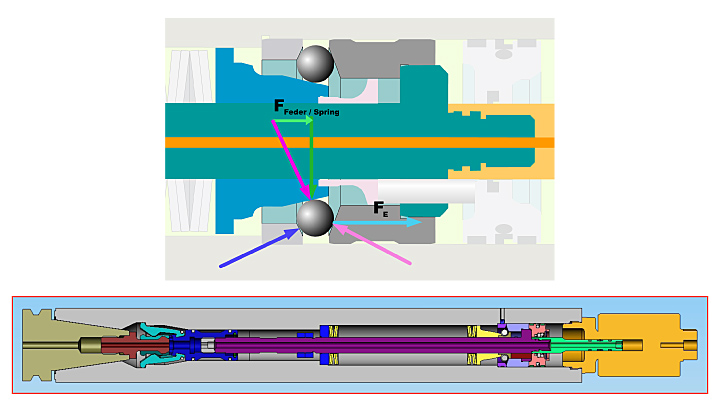

- Transmits clamping force through a Belleville spring mechanism

- Capable of supplying coolant and purging air

- Position controller system (stroke position detection)

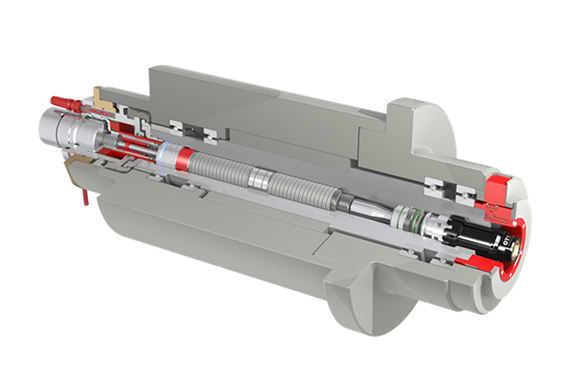

HSK Taper Shank Power Drawbar System

ISO 12164 / JIS B 6064

Compliant with international standards for “dual-contact hollow taper shank”

- Achieves high rigidity through dual-contact design.

- Ensures high torque transmission and precise ATC repeatability.

- Short shank length and lightweight design reduce tool change time.

We provide customized drawbar proposal diagrams to meet your specifications.

HSK Clamping Unit

- Black coating type (standard stock item)

- Finger retention feature

- Short type, for repairs, high-pressure coolant specifications

Etc. can be provided

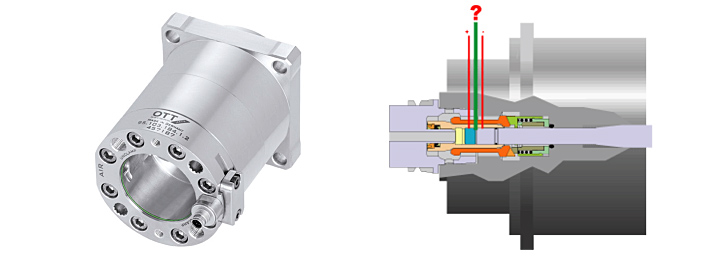

Rotary Union

- Coolant and air supply

- Spindle direct-connection type/Unclamping unit connection type

- 1 channel/2 channel specifications

- Maximum speed 75,000 min -1 available (1K-GDP)

- Leak detection function type available

Unclamp unit

- Wide variety of hydraulic, pneumatic, and electric types

- The reaction force receiving mechanism reduces the load on the spindle bearing.

- Rotary union (1K-GD type) can be installed

- Signal ring for position detection can be built in

Stroke Position Detection System

- Position Controller System

- INWEST (Signal converter with built-in unclamping unit)

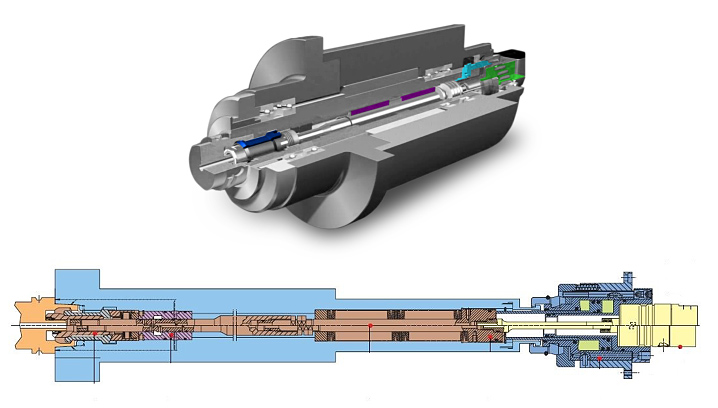

SK/BT shank power drawbar system

MAS / ISO / DIN / ANSI / JIS

『7/24 Taper Shank』 International Standard Compliant

- The spring force can be reduced by approximately half using the boost mechanism, enabling a compact design.

- The pushing force required for unclamping can be reduced.

- Prevents fretting that occurs in the tapered part of the tool holder.

We will create a drawbar proposal that meets your required specifications.