Fukudaco, Japan

Fukudaco Motor Element

Manufacturer: Fukudaco

Overview

ATE designs and manufactures motor elements for both high-speed and low-speed, high-torque applications, providing optimal output in limited spaces. Many industries that demand high output and quality particularly adopt these elements. Their compact design and high performance flexibly meet various customer requirements, making them suitable for fields with the highest demands for performance, quality, and reliability, such as aerospace and medical technology. Additionally, machine tool spindles and pumps widely use these elements as industry-standard products due to their high performance and quality.

Applications

- Machine tool spindles (grinding, milling, drilling, turning)

- Vacuum pumps

- Fans

- Compressors

- Centrifuges

- Pumps for fuel cells

- Motors for BEVs (Battery Electric Vehicles)

Features

- Compact high output

- Highly customizable design

- Low vibration and low noise

- Low power consumption and long lifespan

AC Induction Motors/Brushless DC Motors – Stator/Rotor Unit

- 2-pole, 4-pole, 6-pole, 8-pole configurations

- Highest standard in motor efficiency

- Maximum rotational speed: 1,000,000 min-1

- Maximum stator outer diameter: 580 mm

- Generates up to 2500 Nm of torque

- Can incorporate PTC thermistors or KTY sensors in the stator coil ends to prevent motor overheating

Other specifications are also available upon request.

Stator

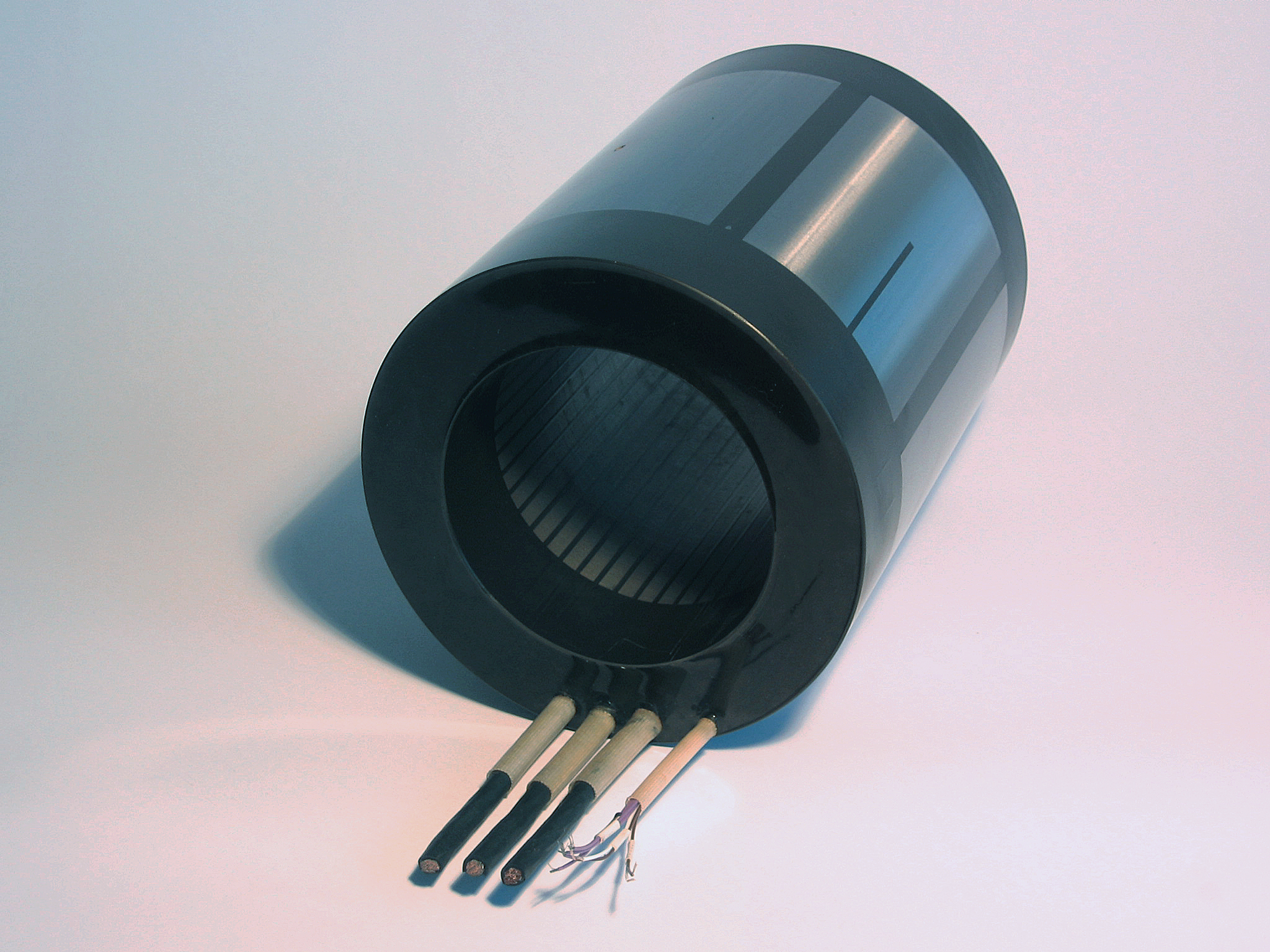

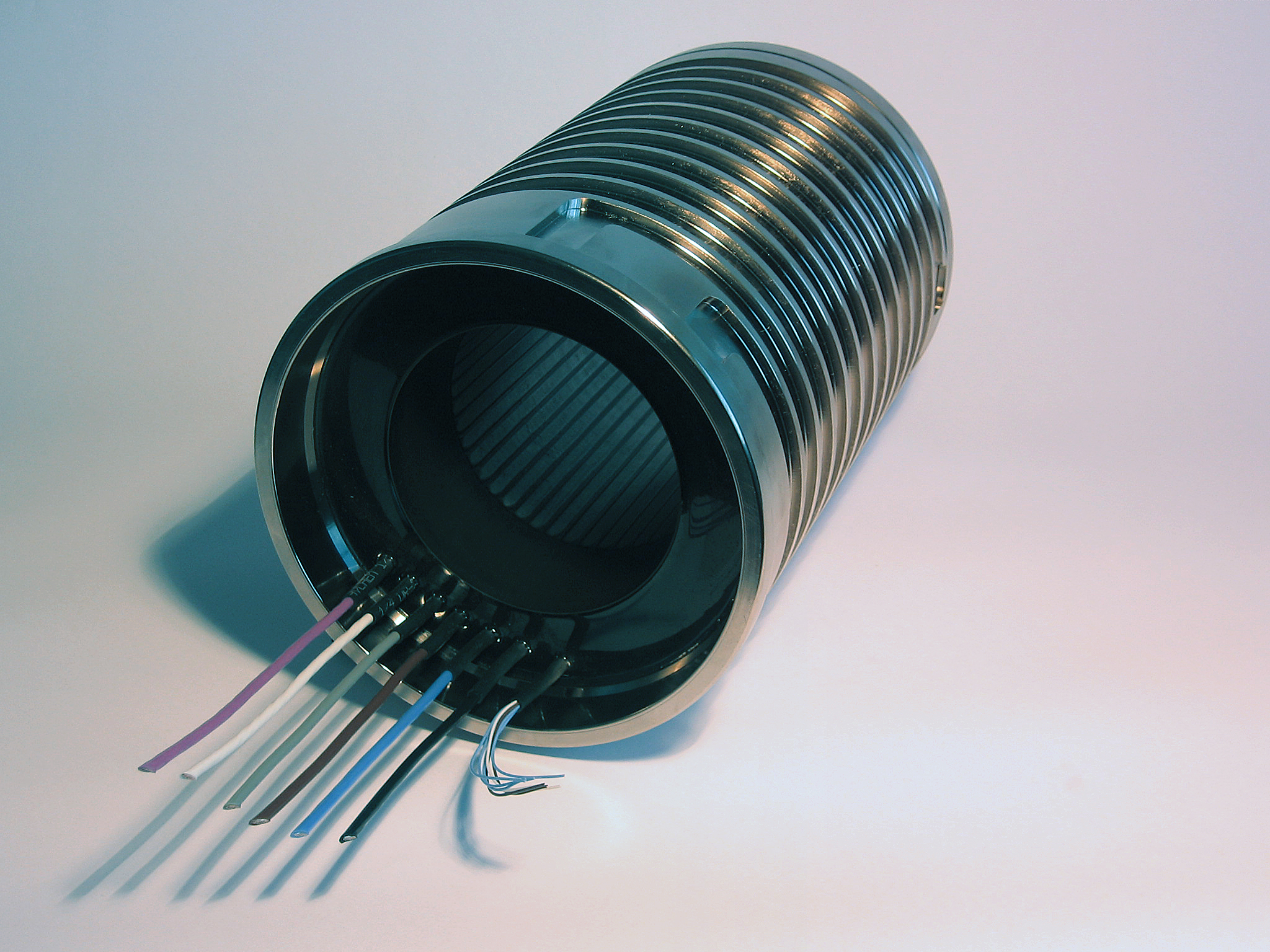

Molded Stator

Molded Stator with Cooling Jacket

After assembling the stator with a cooling jacket provided by the customer, a molding process is applied.

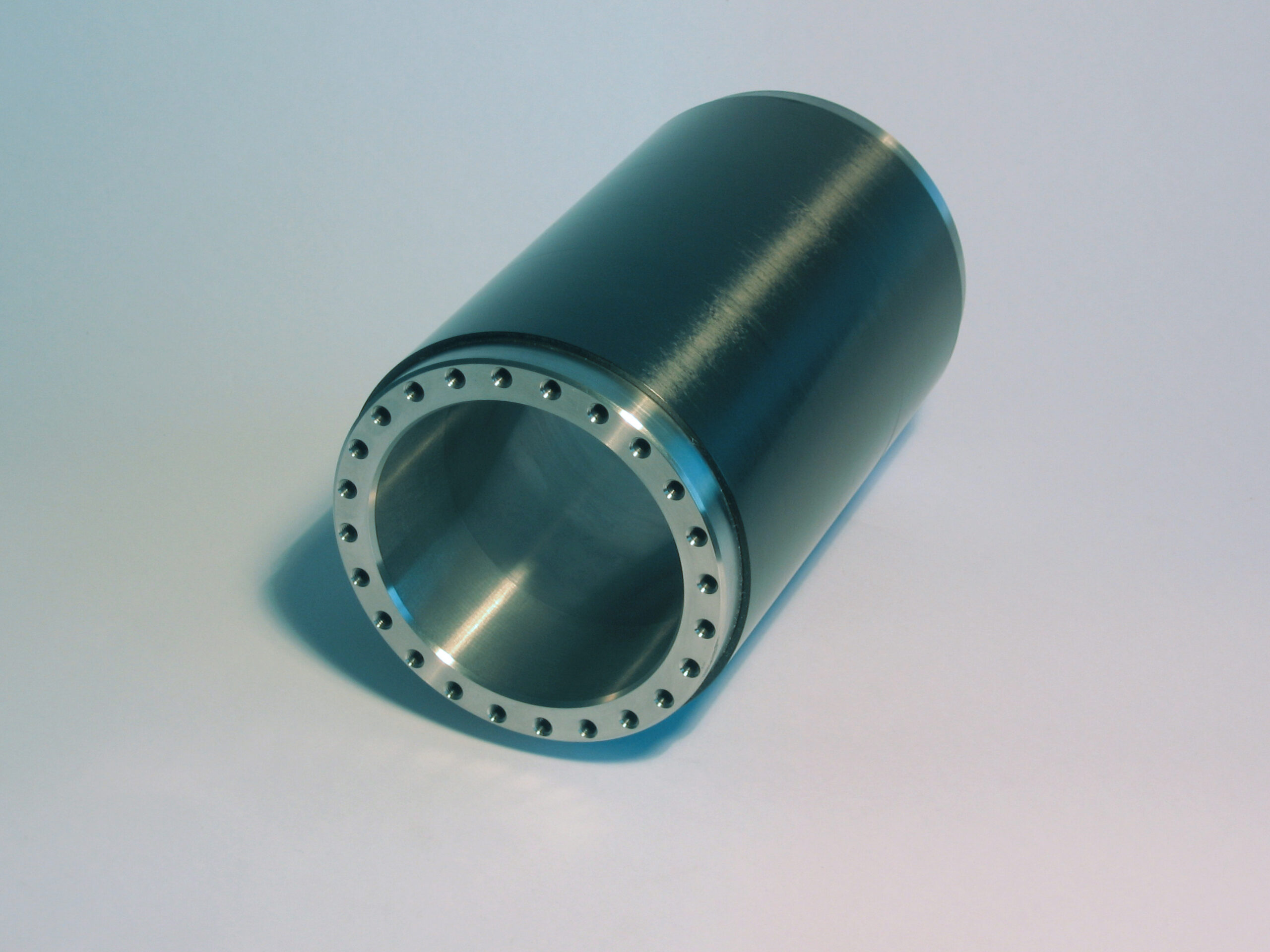

Rotor

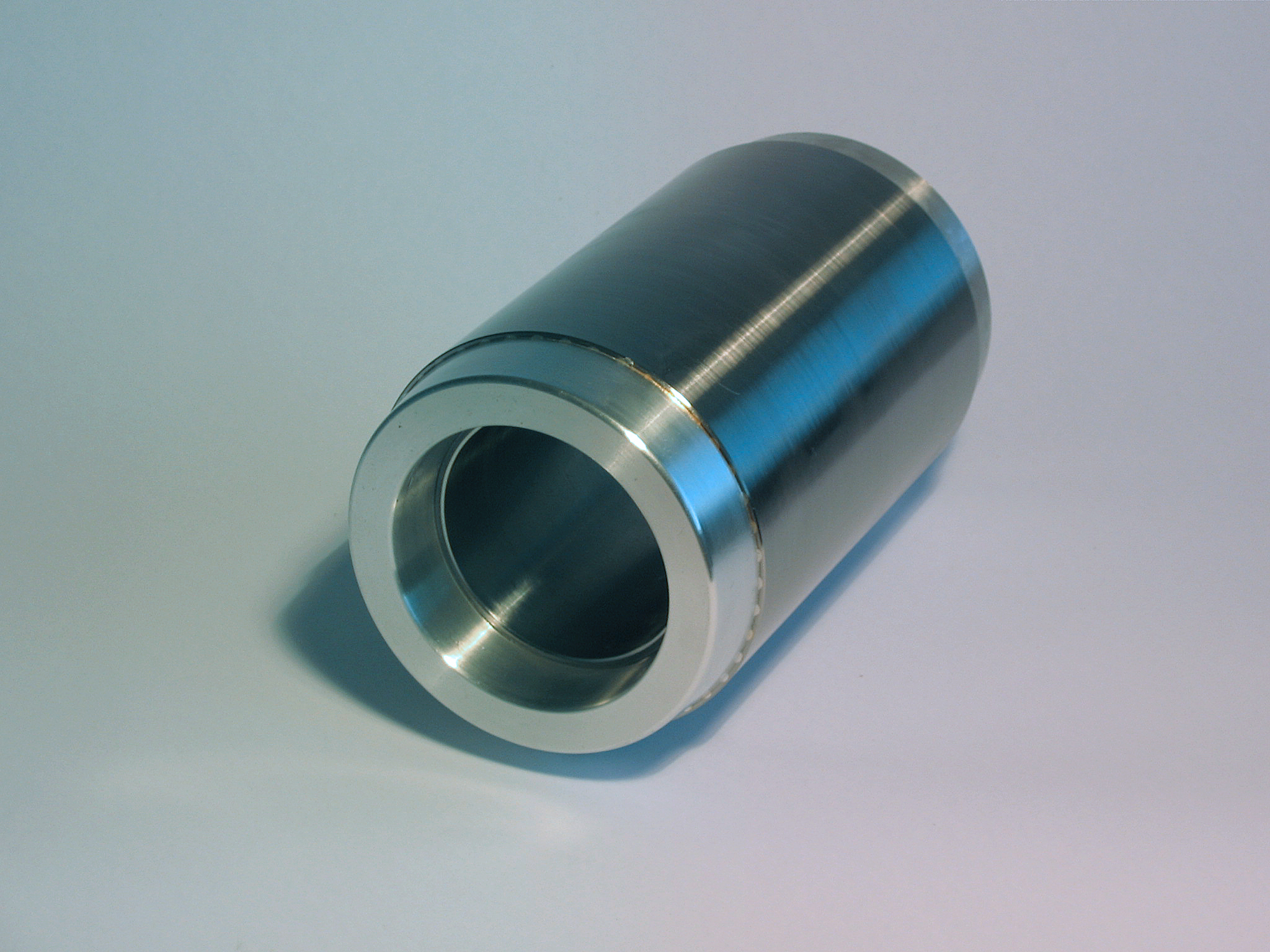

Aluminum Rotor

A squirrel cage rotor made from aluminum die-casting.

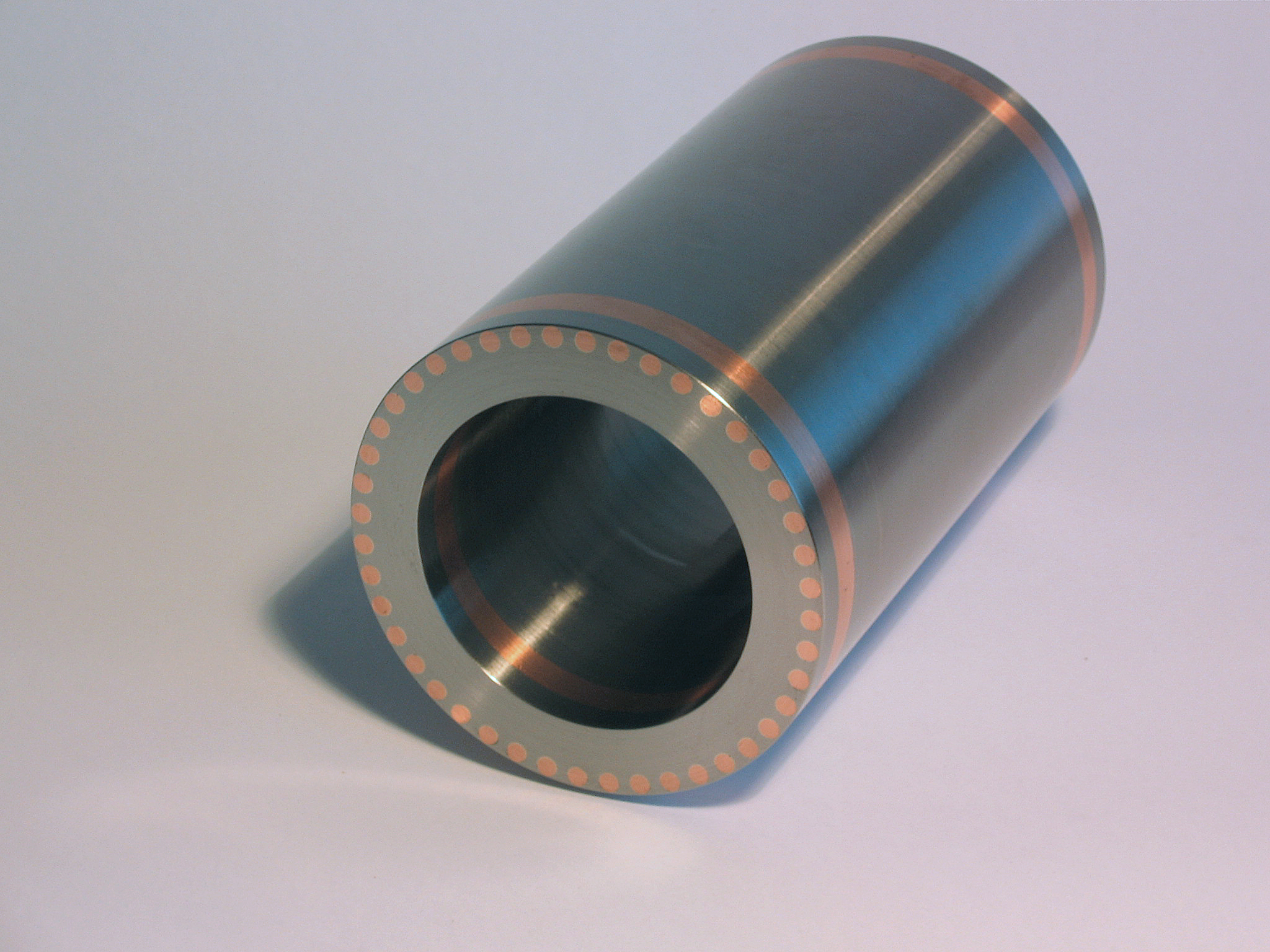

Copper Rotor

The squirrel cage is composed of copper bars and copper end rings. For high-speed specifications, reinforcement rings are attached to maintain high rigidity. Compared to aluminum rotors produced by casting, copper rotors offer greater design flexibility.

Magnet Rotor (Direct Shaft Mounting)

Permanent magnets and reinforcement rings are mounted on a shaft provided by the customer, maximizing the shaft diameter. Using powerful permanent magnets in the rotor delivers a high power-to-weight ratio.

Magnet Rotor (Magnet Carrier Method)

Permanent magnets and reinforcement rings are mounted on a magnet carrier provided by the customer. The supplied rotor is assembled onto the shaft using a shrink-fit method.

DD (Direct Drive) Motor

- Rotary Table

- Milling Head

- spindle

- Wind turbines, hydroelectric generators

- Extrusion Machine

- The parabolic antenna rotation axis

Stator outer diameter: φ30 to 800 mm

Rotation speed: up to 26,000 min -1

Number of poles: up to 132

Torque: up to 1,240 Nm (peak)

*We can also accommodate specifications other than those listed above.

Specification

DD motor (inner rotor motor/MS motor)

| Motor type D1/Lfe / Number of poles | D1 | D2 | L | d6 | Rated torque [Nm] | Maximum speed [min -1 ] |

|---|---|---|---|---|---|---|

| MS42/180/6 | 42 | 28 | 202 | 17 | 2.5 | 26000 |

| MS30/50/8 | 30 | 16 | 72 | 12 | 0.22 | 1000 |

| MS60/60/8 | 60 | 41 | 89 | 32 | 2.8 | 12000 |

| MS80/80/8 | 80 | 55 | 112 | 45 | 9 | 5000 |

| MS80/40/10 | 80 | 55 | 66 | 38 | 4 | 15000 |

| MS120/120/10 | 120 | 85 | 175 | 60 | 25 | 10000 |

| MS54/100/14 | 54 | 38 | 127 | 25 | 4 | 8000 |

| MS90/80/14 | 90 | 62 | 102 | 52 | 16 | 5000 |

| MS250/300/14 | 250 | 190 | 380 | 140 | 600 | 4000 |

| MS60/30/22 | 60 | 44 | 52 | 38 | 1.75 | 2000 |

| MS100/95/22 | 100 | 65 | 130 | 56 | 29 | 2000 |

| MS180/100/22 | 180 | 115 | 150 | 90 | 120 | 2000 |

| MS210/70/38 | 210 | 170 | 110 | 140 | 150 | 3000 |

| MS220/290/38 | 220 | 170 | 344 | 140 | 600 | 2000 |

| MS370/450/38 | 370 | 280 | 535 | 220 | 2400 | 800 |

| MS450/200/38 | 450 | 346 | 280 | 300 | 2000 | 1500 |

| MS580/300/38 | 580 | 446 | 400 | 380 | 5000 | 2000 |

| MS430/75/40 | 430 | 332 | 115 | 270 | 800 | 800 |

| MS140/22/44 | 140 | 100 | 52 | 77 | 12 | 1500 |

| MS250/40/44 | 250 | 200 | 85 | 130 | 120 | 1000 |

| MS290/30/66 | 290 | 235 | 85 | 210 | 150 | 600 |

| MS340/100/66 | 340 | 280 | 160 | 240 | 620 | 800 |

| MS520/150/88 | 520 | 450 | 220 | 400 | 2000 | 500 |

| MS800/150/88 | 800 | 680 | 240 | 620 | 5000 | 300 |

| MS760/430/132 | 760 | 690 | 535 | 675 | 2000 | 200 |

DD motor (outer rotor motor/AL motor)

| Motor type D1/Lfe/number of poles | D1 | D2 | L | d5 | Rated torque [Nm] | Maximum speed [min -1 ] |

|---|---|---|---|---|---|---|

| AL47/30/14 | 34 | 15 | 37 | 47 | 1 | 3000 |

| AL450/200/16 | 390 | 250 | 310 | 450 | 1000 | 2500 |

| AL60/80/22 | 52 | twenty four | 107 | 60 | 3.5 | 2000 |

| AL160/50/44 | 138 | 91 | 80 | 160 | 32 | 2000 |

| AL200/15/44 | 179 | 130 | 55 | 200 | 29 | 2000 |

| AL270/70/44 | 238 | 155 | 160 | 270 | 300 | 1800 |

| AL435/125/66 | 410 | 338 | 160 | 435 | 1370 | 800 |

| AL555/175/88 | 529 | 458 | 210 | 555 | 3300 | 500 |