Fukudaco, Japan

Fukudaco Precision Lock Nuts (ZM/ZMV/ZMT/ZMN)

Manufacturer: Fukudaco

Overview

Applications

- Machine tool spindles

- Precision rotating machinery

- Other precision equipment

Features

- ZM: Standard specification

- ZMV: Axial locking

- ZMT: Ultra-precision applications

- ZMN: Extreme ultra-precision applications

FKD Precision Lock Nuts

Manufactured domestically since 1985 under a license agreement between Gewinde Ziegler AG (Switzerland) and Fukuda Trading Co., Ltd., FKD precision lock nuts are a proprietary brand product.

All FKD brand nuts are produced under management systems based on ISO9001/ISO14001. With advancements in machining technology, components such as bearings, shafts, and housings require high-precision nuts to ensure accurate assembly and function.

Simultaneously machining the thread and end face of high-precision nuts minimizes assembly adjustment time and maintains high rotational accuracy of the shaft.

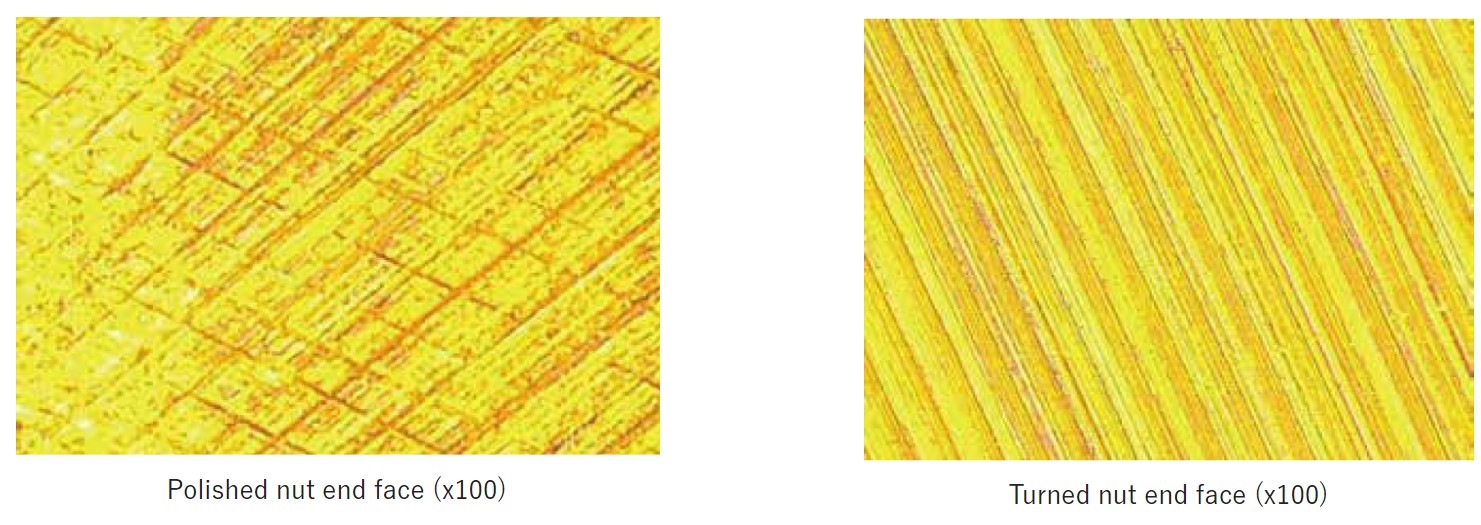

Comparison of the end faces of ground nuts and turned nuts

Polished nuts have a small surface roughness, which improves the contact (degree of adhesion) between the end face and thread surface. They are highly effective in precision applications.

Details of the ZM series

| Features | ||

|---|---|---|

| We simultaneously polish the nut thread surface and end surface, controlling the precision lock nut for squareness. We control the effective diameter of the ZMN nut even more strictly than ISO 4H standards. We also polish the outer diameter and machine-tapped holes to ensure parallelism control and dynamic balancing after installation. | ZM type | 180° x 2 set screws are fixed from the circumferential direction. 60° x 2 high retention type is also available. (ZM-S) |

| ZMV type | 180° x 2 set screws are fixed from the axial direction. 60° x 2 high retention type is also available. (ZMV-S) | |

| Main Applications | ZMT type | 120° x 3 set screws are fixed from the circumferential direction. |

| ● Bearings for machine tool spindles ● Nuts for fixing ball screw support bearings ● Nuts that require precision ● Areas where you want to reduce adjustment time | ZMN type | 120° x 3 set screws for axial fixing. 30° x 12 balance tap holes. 60° x 6 axial and circumferential clamping pin holes. |

| Screw precision | detail | |

| ● ISO standard 4H grade ● Shaft thread 4h recommended | Material: SCM435 Hardness: M85 x 2.0 or less HRC30-37 M90 x 2.0 or more HRC15-20 Surface treatment: Black Coating | |

*Please refer to the catalog for the dimensions/sizes of each nut.

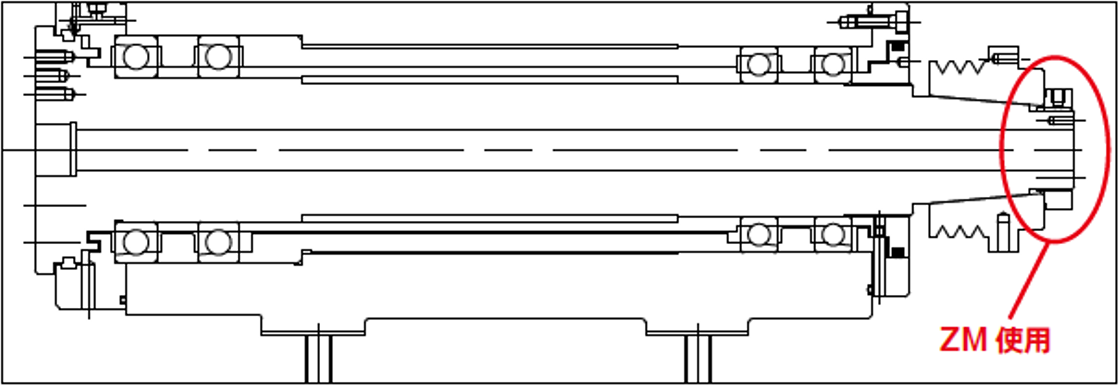

Usage example

Machine tool spindle