Fukudaco, Japan

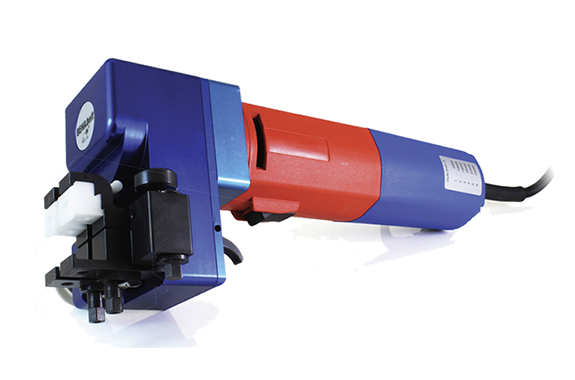

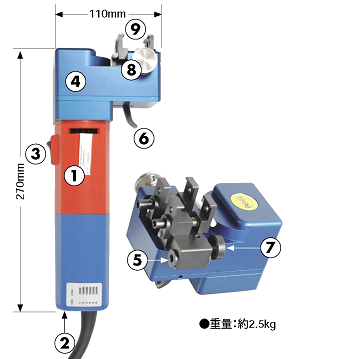

Fukudaco RS-02 Friction Welder

Manufacturer: Fukudaco

Model: RS-02

Overview

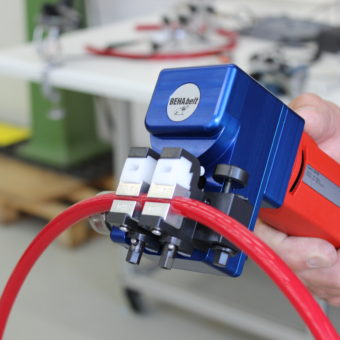

A welding kit for urethane extruded belts.

It generates high-speed vibrations and uses the resulting frictional heat to weld instantly.

Applications

High-speed welding and bonding of polyurethane belts (round belts)

Features

- Instant welding using frictional heat generated by high-speed vibrations

- Safe operation with no heat source, eliminating the risk of burns or fire

- Achieves complete welding without air bubbles

- Cordless, rechargeable battery-powered model

Product Overview

Typically, welding tools used for bonding urethane belts utilize a soldering iron. This method involves heating the soldering iron to a welding temperature and using it to melt both ends of the urethane belt (round belt) to ensure the cross-sections align correctly.

In contrast, BEHA’s friction welder melts the bonding surface using frictional heat generated by high-speed vibrations. This method is faster and results in a stronger bond compared to the traditional method of melting with a soldering iron.

Flow of Welding Urethane Belts (Round Belts)

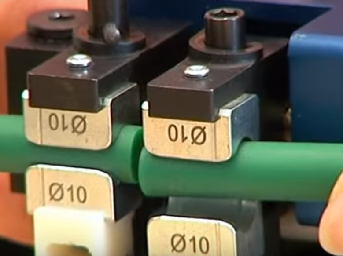

| Step 1:Set one side of the urethane belt. |  |

| Step 2: Set the other side to be welded. |  |

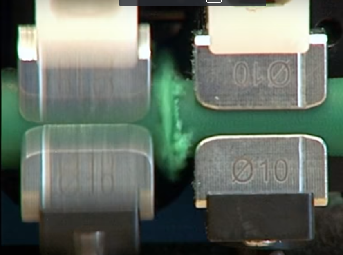

| Step 3: Turn on the switch to start the vibration on one side. |  |

| Step 4: The frictional heat melts and bonds the ends together. |  |

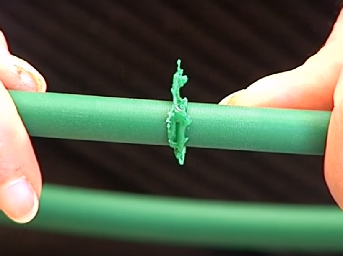

| Step 5: Remove any excess weld material with nippers. |  |

| Step 6: Confirm that the belt is securely fixed. |  |

Basic Specifications

- Drive Motor: 120V/AC with speed control and ON/OFF switch

- High-speed vibration mechanism for friction welding

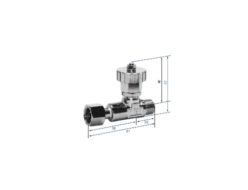

- Equipped with clamp device, centering lever, and release button

- Interchangeable clamp jaws for different profiles:

- Round profile clamp jaws (Φ5-20mm)

- V-profile clamp jaws (6×4-22x14mm)

- Pressure strength adjustment button

|

|

| At BEHA, we also manufacture the following urethane belts:

|