Fukudaco, Japan

Fukudaco SmartCheck Condition Monitoring Device

Manufacturer: Fukudaco

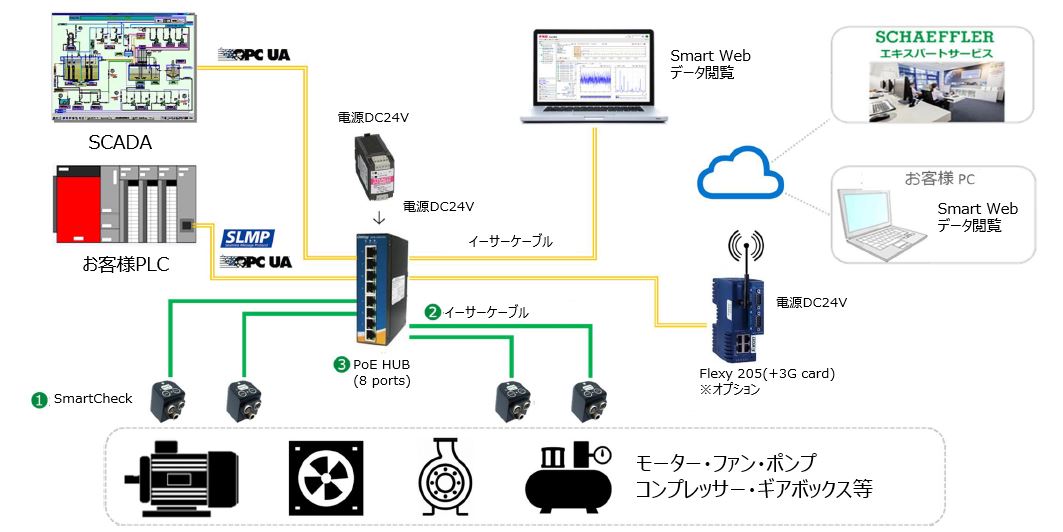

Overview

SmartCheck is a condition-monitoring device that monitors vibration and temperature. By detecting the specific vibration frequencies associated with mechanical element failures, it can identify abnormal vibrations that could lead to unexpected equipment shutdowns and pinpoint the malfunctioning mechanical components.

Applications

- Condition monitoring of various production equipment (rotating machinery)

- Pumps

- Motors

- Fans

- Gearboxes

- Belts

- Compressors

- Vibrating screens

Features

- Condition monitoring through a wide range of vibration (0.8–10kHz) and temperature (-20°C to +70°C)

- Automatic FFT analysis with two-stage alarm notification

- Preloaded with numerous measurement templates to cover various production equipment

- Alarm thresholds are adjustable to match operating conditions, even with variable speed and load fluctuations