Fukudaco, Japan

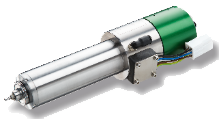

Fukudaco SycoTec Compact High-Frequency Spindle with Inverter

Manufacturer: Fukudaco

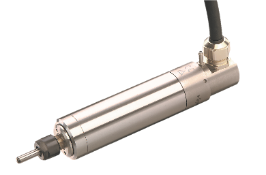

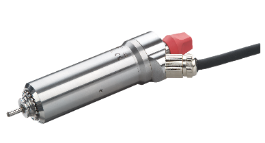

Model: SycoTec

Overview

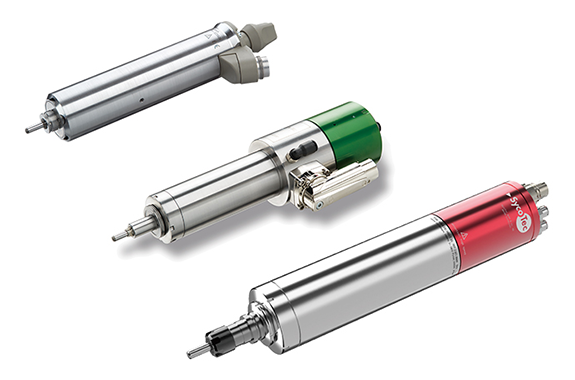

SycoTec offers high-frequency spindles ranging from 100,000 rpm and outputs between 250 W and 5,000 W. By using their own motors, they achieve compact and high-performance capabilities.

Applications

Routing of printed circuit boards.

In addition, we cut materials such as resin and glass, as well as other similar materials.

Light load machining (cutting, grinding).

Machining with robot integration (cutting, deburring).

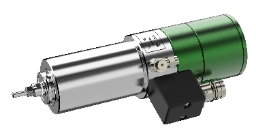

Spindles for dental CAD/CAM systems

Features

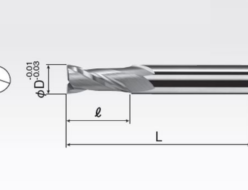

Body diameter: φ25 mm to φ60 mm

Maximum speed: 100,000 rpm

Grease lubrication

Maximum output: 5,000 W

Compact and high-power design with in-house motors

Precision and Power

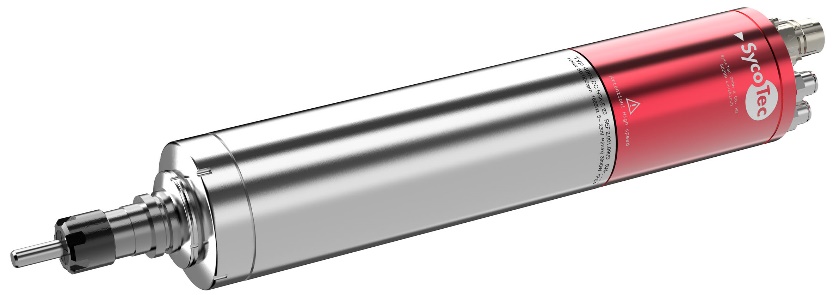

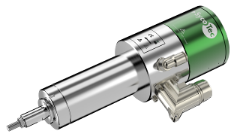

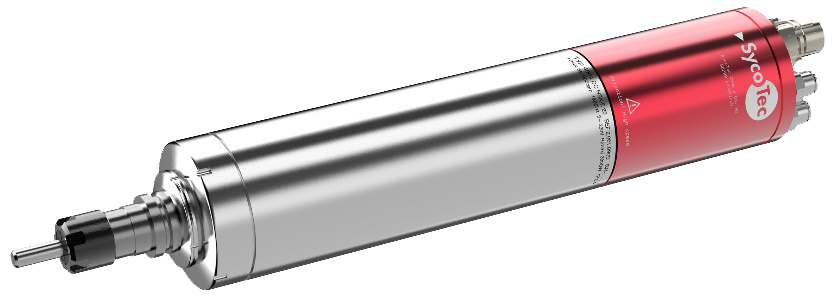

SycoTec supplies high-frequency spindles for diverse applications worldwide. With maintenance-free hybrid ball bearings, stainless steel housings, and motor protection, they ensure maximum performance even under harsh conditionsMoreover, their compact, high-power design stands out, as they achieve it through the use of high-density high-frequency motors that they design and manufacture in-house. Consequently, SycoTec offers the ideal spindle for a variety of applications, ensuring precision and power in every use.

Optimal power density with in-house designed and manufactured high-frequency motors

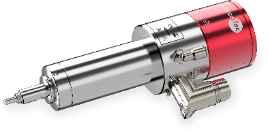

In spindle design, the built-in motor is a crucial element. By increasing power density, it is possible to design a compact motor. A compact motor allows the spindle to be smaller and lighter while still delivering high output. The SycoTec motor spindle 4064 DC-HSK25 is a prime example of this. With a body diameter of just 60 mm, the spindle houses a motor that delivers up to 5,000 W of power.

Main Fields of Use and Applications

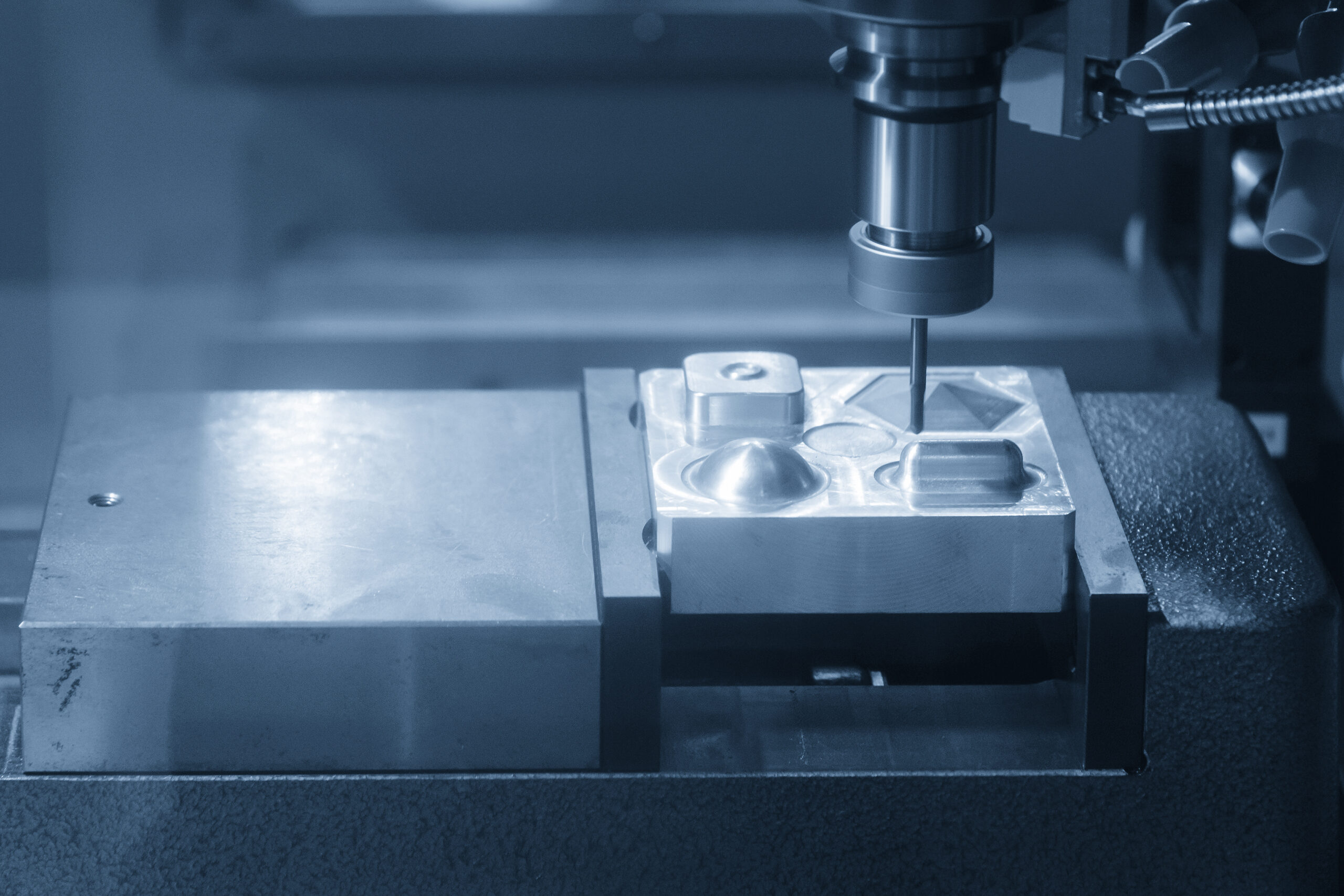

Machine Tools

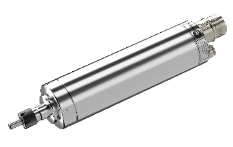

Medical and Dental

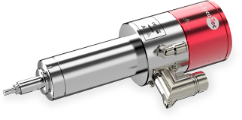

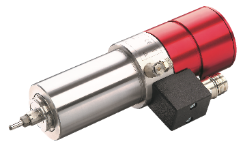

Drive systems used in modern dental and medical technology processes must meet many requirements beyond precision, such as efficiency and cost. For over half a century, SycoTec has been involved in various drive systems for the dental industry, consistently providing cutting-edge technology. One of their significant contributions is their powerful high-frequency drive systems, which play a crucial role in creating dental prosthetics from materials such as plastic, ceramic, or metal. These systems ensure rapid, safe, and reliable execution of numerous dental applications and instruments, including CAD/CAM systems. The 4033 AC series is particularly used for this purpose.

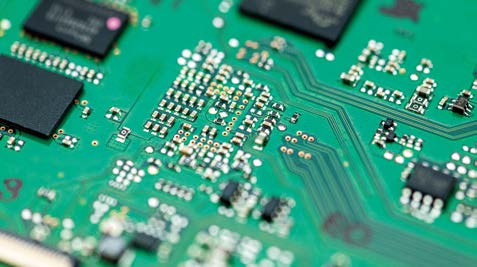

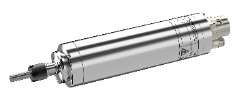

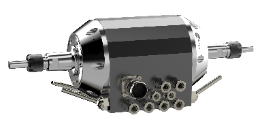

Electronic Circuit Boards

Today, all devices rely on electronic components. From fully-automated coffee makers to smartphones, computers, internet-enabled TVs, and automobiles, electronic components are used in products that directly impact our daily lives. Consequently, the machining of electronic circuit boards is recognized as a crucial technology worldwide, with continuous development efforts. SycoTec is also actively engaged in developing spindles that are ideal for machining electronic circuit boards. Notably, the SycoTec 4025 has been a long-standing bestseller in this field.

Key spindles used for this application include the 4033 AC-ESD and 4041 HY-ESD-BW, which feature technology to prevent spindle shaft electrostatic discharge (ESD). These spindles use carbon brushes to make contact with the shaft, allowing any electrical charge on the shaft to flow into the spindle housing, thereby preventing discharge onto the circuit boards.

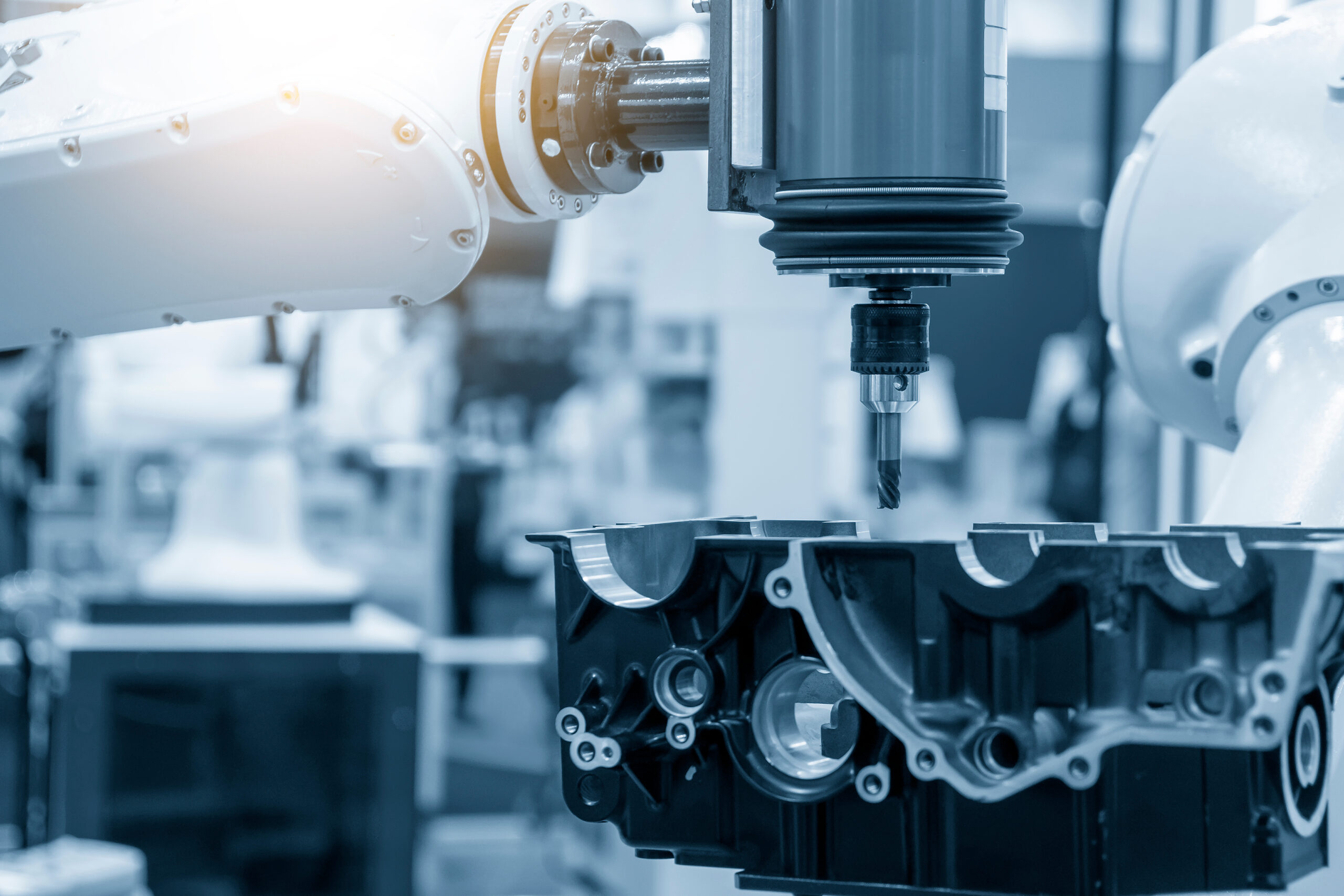

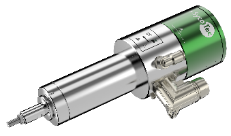

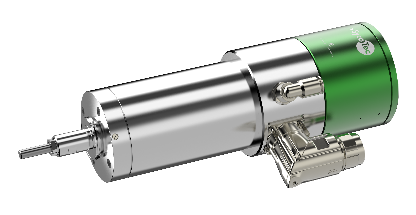

Robotics

Robotic applications open up entirely new possibilities for industrial production. They enhance the flexibility and efficiency of manufacturing processes, execute complex machining tasks, and operate in environments unsuitable for humans. However, spindles used in manufacturing robots must be both powerful and lightweight. SycoTec offers a wide range of motor spindles, particularly in the output range of 1,050 to 5,000 W, providing drives that meet these needs. For this application, the 4060 ER, 4060 ER-S, and 50100 AC-duo models are employed. Thanks to SycoTec spindles’ high power density, they deliver lightweight yet powerful performance, making them ideal for robotic use.

Advertising Design

SycoTec’s spindles are also making a significant impact in the advertising field. When cutting materials are used in advertising, lightweight and powerful spindles are essential. For this application, the 4064 DC-HSK25 is recommended. Despite having a body diameter of just φ60 mm, this spindle can deliver a maximum output of 5000 W and reach speeds up to 50,000 rpm. This allows it to cut through various materials used in advertising, from resin and glass to stainless steel.

SycoTec’s spindles are also making a significant impact in the advertising field. When cutting materials are used in advertising, lightweight and powerful spindles are essential. For this application, the 4064 DC-HSK25 is recommended. Despite having a body diameter of just φ60 mm, this spindle can deliver a maximum output of 5000 W and reach speeds up to 50,000 rpm. This allows it to cut through various materials used in advertising, from resin and glass to stainless steel.

Product Lineup

AC Motor Spindle |  Inverter |  |

AC Motor Spindle

| Model | Basic body diameter φ mm | Maximum RPM min -1 | Output W | Shank diameter φ mm | Tool change | |

| 4025 |  | 33 | 60,000 | 250 | 0.3 to 4.0 | Manual |

| 4026 |  | 33 | 60,000 | 250 | 0.5–4.0 | Manual |

| 4033 AC-CS /4033 AC-ESD-CS |  | 33 | 100,000 | 500 | ≤ 4.0 | Automatic |

| 4033 AC-LN15-CS /4033 AC-LN15-ESD-CS |  | 33 | 80,000 | 500 | ≤ 4.0 | Automatic |

| 4033 AC-ST-60-CS |  | 33 | 60,000 | 500 | ≤ 4.0 | Automatic |

| 4033 AC-ESD-LS-ST-60-CS |  | 33 | 60,000 | 500 | ≤ 4.0 | Automatic |

| 4033 AC-ER8 |  | 33 | 100,000 | 500 | ≤ 5.0 | Manual |

| 4040 |  | 45 | 50,000 | 500 | 1.0 to 6.35 | Manual |

| 5045 AC-ER11 |  | 45 | 60,000 | 1,280 | ≤ 8.0 | Manual |

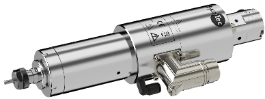

| 4041 /4041HY-ESD |  | 45 | 50,000 | 500 | 1.0 to 6.35 | Automatic |

| 4041 HY-ESD-BW |  | 45 | 50,000 | 500 | 1.0 to 6.35 | Automatic |

| 5045 AC-C5 |  | 45 | 60,000 | 1,280 | ≤ 6.0 | Automatic |

| 4060 |  | 60 | 50,000 | 1,800 | 1.0 to 6.35 | Manual |

| 4060 AC-T |  | 60 | 20,000 | 1,500 | 1.0 to 6.35 | Manual |

| 4060ER |  | 60 | 24,000 | 2,000 | 0.5 to 8.0 | Manual |

| 4060ER-S |  | 60 | 50,000 | 2,000 | 0.5 to 8.0 | Manual |

| 4061 AC-CS-TC |  | 60 | 50,000 | 1,800 | 1.0 to 6.35 | Automatic |

| 5060 AC-C5-60-30-ESD |  | 60 | 60,000 | 3,600 | ≤ 6.0 | Automatic |

| 50100 AC-duo |  | – | 50,000 | 3,000 | 0.5 to 10.32 | Manual |

DC Motor Spindle

| Model | Basic body diameter φ mm | Maximum RPM min -1 | Output W | Shank diameter φ mm | Tool change | |

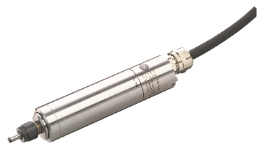

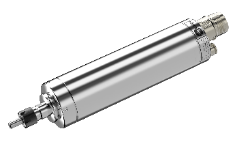

| 4015DC /4015DC-M |  | 25.4 | 80,000 | 300 | 0.5–4.0 | Manual |

| 4015 DC-R |  | 25.4 | 80,000 | 300 | 0.5–4.0 | Manual |

| 4025 DC-S /4025 DC-S Sealing Air |  | 33 | 80,000 | 670 | 0.3 to 4.0 | Manual |

| 4025 DC-T /4025 DC-T Sealing Air |  | 33 | 30,000 | 470 | 0.3 to 4.0 | Manual |

| 4033 DC |  | 33 | 100,000 | 870 | ≤ 4.0 | Automatic |

| 4033 DC-T-CS |  | 33 | 60,000 | 900 | ≤ 4.0 | Automatic |

| 4033 DC-T-ER8 |  | 33 | 60,000 | 900 | ≤ 5.0 | Manual |

| 4036 DC-T |  | 36 | 60,000 | 900 | ≤ 4.0 | Automatic |

| 4036 DC-T-ER11 |  | 36 | 60,000 | 900 | ≤ 8.0 | Manual |

| 5045 DC-ER11 |  | 45 | 60,000 | 3,700 | ≤ 8.0 | Manual |

| 4040 DC-S |  | 45 | 50,000 | 1,050 | 1.0 to 6.35 | Manual |

| 4040 DC-S-ER-DD |  | 45 | 50,000 | 850 | ≤ 8.0 | Manual |

| 4041 DC-S |  | 45 | 50,000 | 1,050 | 1.0 to 6.35 | Automatic |

| 5045 DC-C5 |  | 45 | 60,000 | 3,700 | ≤ 6.0 | Automatic |

| 4060 DC-S |  | 60 | 60,000 | 3,000 | 1.0 to 6.35 | Manual |

| 4061 DC-S-CS-TC |  | 60 | 60,000 | 3,000 | 1.0 to 6.35 | Automatic |

| 4061 DC-T |  | 60 | 25,000 | 2,800 | 1.0 to 6.35 | Automatic |

| 4064 DC-HSK25 |  | 60 | 50,000 | 5,000 | 1.0 to 10.0 | Automatic |

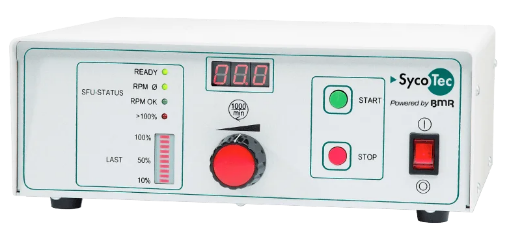

Inverter

| Model | Target spindle | ||

| AC Motor | DC Motor | ||

| e@syDrive4624 |  | 4025/4026/4033AC * | 4015DC / 4025DC-S * / 4025DC-T * |

| e@syDrive4625 | 4033AC/4040/4041 /4041HY-ESD /4041HY-ESD-BW | 4025DC-S / 4025DC-T / 4033DC * / 4033DC-T * / 4036DC-T * / 4040DC-S / 4041DC-S | |

| e@syDrive4626 | 4033AC/4040/4041 /4041HY-ESD /4041HY-ESD-BW | 4025DC-S / 4025DC-T / 4033DC / 4033DC-T / 4036DC-T / 4040DC-S / 4041DC-S | |

| e@syDrive4638 |  | 4060/4060AC-T /4060ER/4060ER-S /4061AC-CS-TC /5045AC /50100AC-duo | 4060DC-S / 4060DC-T / 4060DC-S-CS-TC / 4061DC-T / 5045DC / 4064DC-HSK25 |

| e@syDrive TV4504 |  | 4025/4026/4033AC * | 4015DC/4025DC-T * |

*Output will decrease.