It is a high-capacity automatic air release valve, even in a compact form.

Features

When the valve is closed, the structure completely separates the valve body from the float, so there is no water leakage caused by pipe vibrations or pulsations.

All parts are made from non-rusting materials, so there is no concern about rust-contaminated water.

Thanks to its unique design, it offers extremely high air discharge capacity despite its compact size.

If the piping or device becomes negatively pressurized, it quickly draws in a large volume of air to prevent equipment damage.

The float is made of molded synthetic resin, so there is no risk of collapse or water absorption due to pressure.

Specifications

| Applicable fluid | Cold and hot water |

| Nominal diameter | 15–25 mm |

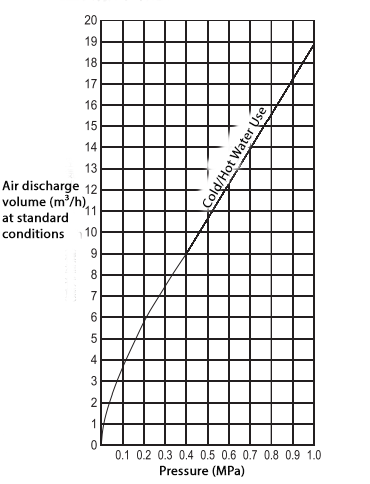

| Maximum operating pressure | 1.0 MPa |

| Maximum operating temperature | 90°C |

| Valve body | Brass (Electroless nickel plated) |

| Valve | Synthetic rubber |

| Valve seat | Phosphor bronze |

| Float | Synthetic resin |

| Pipe connection | Threaded type JIS Rc |

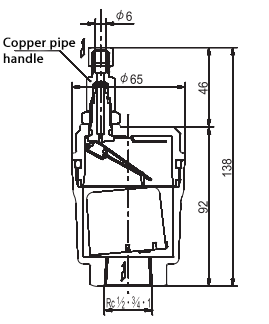

Structure / Dimensions

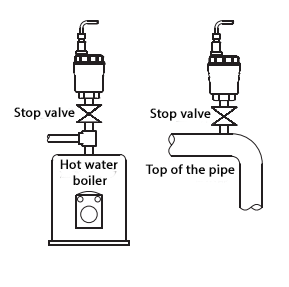

Installation Examples

Air Discharge Capacity

Precautions When Installing

Install the valve as vertically as possible at the highest point of the piping or equipment.

Attach a stop valve at the inlet to allow water stoppage during maintenance or inspection.

When starting the system for the first time, close the stop valve above and fully flush out any debris or foreign objects from inside the pipe to prevent them from entering the air release valve. Then, open the stop valve completely.

There is a risk of water leakage if debris sticks to the air release valve body. Attach a φ6 mm outer diameter copper pipe to the valve outlet and lead it to a drain or other safe outlet. When connecting vinyl tubes, remove the copper pipe fitting.

For other details on installation, please read the instruction manual included with the product.