Fushiman Co.

Fushiman J102 type ball joint

Manufacturer: Fushiman Co.,LTD.

Model: J102

| Model | Nominal diameter | Method | Fluid | Maximum Operating Pressure | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|---|

| J102 | 65-300 | Ball | Steam Gas Liquid | 2.0 MPa | 220°C | SCPH | Butt Welding |

Application

- Pipelines that expand and contract due to changes in outside temperature or differences in the temperature of transported fluids.

- Pipelines where ground subsidence causes misalignment in equipment or tanks.

- Pipelines that may shift due to natural disasters such as wind or earthquakes.

- Pipelines affected by twisting or rotational forces.

- Pipelines in seismic-isolated buildings that must absorb building-to-ground movement (vertical, horizontal, or diagonal).

Specification

| Item | Specification |

|---|---|

| Nominal Diameter | 20–300 |

| Maximum Operating Pressure | 2.0 MPa |

| Pressure Test | 4.0 MPa |

| Maximum Operating Temperature | 220°C |

| Fluid | Steam, hot/cold water, air, and oil |

| Pipe Connection | 20–50: Threaded type, 65–300: Welded type |

Features

Compliant Product

Complies with SHASE-S 007 (Standard of the Society of Heating, Air-Conditioning and Sanitary Engineers of Japan).Absorbs Large Expansion in Compact Space

Suitable for long pipelines in large factories or university district heating systems. Fewer joints and supports are needed, reducing installation cost compared to other joints.Wide Application Range and Long Life

Uses a unique packing material with excellent heat, cold, oil, wear, and corrosion resistance.Strong Fixation Even with Low Torque

Requires only small torque for rotation during expansion and contraction. Also reduces need for piping guides and restraints, lowering overall cost.Rust-Proof Processed Ball

The ball undergoes industrial chrome plating to prevent damage to the gasket caused by rust.Air-Tight Construction with No Leaks

A simple packing and seal structure ensures improved airtightness.Simultaneous Absorption of All Movements

Absorbs various movements including piping displacement, bending, twisting, and rotation.Robust Structure

Offers greater durability and water hammer resistance compared to other types of joints.Predicts Mutual Interference

Can simulate mutual interference at the design stage, ensuring safety verification in advance.

Structure / Part Name / Material

| Part Name | Material | Part Name | Material |

|---|---|---|---|

| Body | 20–50: FCD400 65–300: SCPH2 | Packing D Cover | Fluororubber FCD450 |

| Ball | 20–50: FCD400 (Industrial Chrome Plated) 65–300: STKM13A (Industrial Chrome Plated) | Hex Bolt Embedded Bolt | SUS304 SUS304 |

| Packing A | Fluororubber | Hex Nut | SWCH |

| Packing B | Fluororubber | Pipe | STPG370 |

| Packing C | Fluororubber |

Note

- The fluid-contacting parts can also be made of stainless steel.

- The connection shape can also be changed to a flange type.

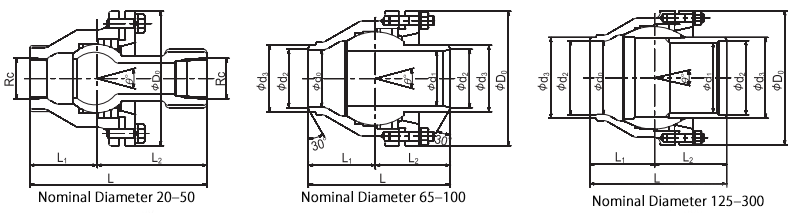

Dimensions / Performance / Weight

| Part/Nominal Diameter | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face-to-Face Length (L) | 145 | 145 | 155 | 170 | 190 | 190 | 190 | 230 | 260 | 280 | 300 | 340 | 390 |

| L₁ | 55 | 50 | 55 | 65 | 70 | 80 | 80 | 120 | 120 | 130 | 140 | 160 | 190 |

| L₂ | 90 | 95 | 100 | 105 | 120 | 90 | 110 | 110 | 140 | 150 | 160 | 180 | 200 |

| Outer Diameter (D₀) | 110 | 110 | 120 | 135 | 155 | 165 | 180 | 225 | 260 | 275 | 340 | 420 | 475 |

| Thread Size (Rc) | ¾ | 1 | 1¼ | 1½ | 2 | — | — | — | — | — | — | — | — |

| d₀ | — | — | — | — | — | 65 | 77 | 101.5 | 125 | 150 | 200 | 250 | 297 |

| d₁ | — | — | — | — | — | 58.3 | 73 | 95 | 120.8 | 143.2 | 190.9 | 237.2 | 283.7 |

| d₂ | — | — | — | — | — | 65.9 | 78.1 | 102.3 | 126.6 | 151.7 | 200 | 250 | 297.9 |

| d₃ | — | — | — | — | — | 76.3 | 89.1 | 114.3 | 139.8 | 165.2 | 216.3 | 267.4 | 318.5 |

| Max Bending Angle (θ°) | 30 | 30 | 30 | 30 | 30 | 25 | 25 | 25 | 25 | 25 | 20 | 16 | 16 |

| Weight (kg) | 2.7 | 2.7 | 3.2 | 5.0 | 7.0 | 9.1 | 13 | 23 | 31 | 37 | 52 | 96 | 135 |

Precautions for Use

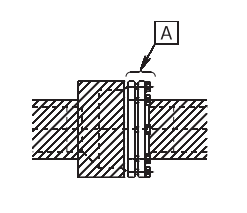

- After air or water flow begins, if signs of leakage appear during use, please tighten the hex bolts or hex nuts on the cover evenly by about 6–1 full turns.

Do not insulate area A as shown in the diagram on the right. - Avoid using the product at an inclination exceeding the maximum allowable bending angle (θ° = 8°).

If this angle is exceeded, check and correct the fixings and guides as needed.