Fushiman Co.

Fushiman JOB31T type expansion joint (double type)

Manufacturer: Fushiman Co.,LTD.

Model: JOB31T

| Model | Nominal diameter | Method | Fluid | Maximum Operating Pressure | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|---|

| JOB31T | 20–500 | Bellows | Steam Gas Liquid | 1.0 MPa | 220°C | SS | Flanges |

Application

For absorbing expansion and contraction in piping.

Quality

Compliant with JIS B 2352 standard

Specifications

| Nominal Diameter | 20–500 |

| Maximum Operating Pressure | 1.0 MPa |

| Pressure Test | 1.5 MPa |

| Maximum Operating Temperature | 220°C |

| Fluid | Steam, hot/cold water, oil, and non-corrosive gases |

| Pipe Connection | Flange JIS 10K |

Features

- Complies with JIS B 2352 — Designed according to JIS B 2352-2013 Appendix JD (Reference) “Product specification example of bellows-type expansion joints (Application A)”.

- Bellows are made of low-carbon SUS316L — Prevents carbon precipitation from welding and provides excellent durability against intergranular corrosion and pitting.

- All wetted parts are stainless steel — Safe for clean or chemical fluids without concern.

- No packing is used — Completely leak-free.

- Inner pipe is SUS316L — Prevents pressure loss and flow-induced vibration, improving durability.

Caution for Use

Do not use the expansion joint in a state that exceeds the maximum or minimum face-to-face dimensions. If the specified face-to-face dimension is exceeded, please inspect and correct the fixings, guides, etc.

For the duplex type, the anchor base of the product is also fixed in the middle.

Structure / Part Name / Material

| Part Name | Material | Part Name | Material |

|---|---|---|---|

| Tension Flange | SUS316L | Inner Tube | SUS316L |

| Pipe Flange | SS400 | Face-to-Face Fixing Bolt | SS400 |

| Outer Tube | SPHC or SS400 | Face-to-Face Fixing Plate (20–250A) | SS400 |

| Bellows | SUS316L | Reinforcement Ring (300–500A) | SS400 |

| Part Name | Material | Part Name | Material |

|---|---|---|---|

| Tension Flange | SUS316L | Face-to-Face Fixing Bolt | SS400 |

| Pipe Flange | SS400 | Face-to-Face Fixing Plate (20–250A) | SPHC or SS400 |

| Outer Tube | SPHC or SS400 | Reinforcement Ring (300–500A) | SS400 |

| Bellows | SUS316L | Anchor Base | SS400 |

| Inner Tube | SUS316L |

Dimensions / Performance / Mass

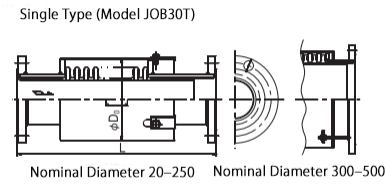

Single Type: JOB30T Model

| Part/Nominal Diameter | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Set Face-to-Face Length (L) | 365 | 415 | 440 | 465 | 490 | ||||||||||||

| Maximum Face-to-Face (L₁) | 375 | 425 | 450 | 475 | 500 | ||||||||||||

| Minimum Face-to-Face (L₂) | 340 | 390 | 415 | 440 | 465 | ||||||||||||

| Max. Stroke (δ) | Stretch: 10 / Shrink: 25 (※) | ||||||||||||||||

| Outer Diameter (D₀) | 58 | 73 | 98 | 110 | 136 | 162 | 212 | 235 | 292 | 333 | 387 | 422 | 470 | 517 | 567 | ||

| Mass (kg) | 3.5 | 4.5 | 5.5 | 6 | 7.5 | 11 | 12 | 16 | 21 | 27 | 36 | 52 | 111 | 130 | 160 | 186 | 208 |

Note (※1):

Shrink amount δc = 35 mm is also available (Model JOB24L, nominal diameter 20–200. Not a JIS standard product).

Supplement 1:

The value δ is the difference between the maximum and minimum face-to-face lengths. We use this method especially when high precision is not required.

Supplement 2:

After hydraulic pressure testing, be sure to remove both the face-to-face fixing bolts and plates for nominal diameters 20–250, and the fixing bolts for nominal diameters 300–500.

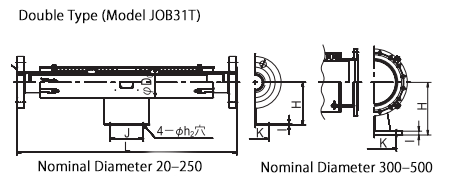

Double Type: JOB31T Model

| Part/Nominal Diameter | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| Set Face-to-Face Length (L) | 680 | 780 | 880 | 930 | 980 | 1030 | 1080 | |||||||||||

| Maximum Face-to-Face (L₁) | 700 | 800 | 900 | 950 | 1000 | 1050 | 1100 | |||||||||||

| Minimum Face-to-Face (L₂) | 630 | 730 | 830 | 880 | 930 | 980 | 1030 | |||||||||||

| Max. Stroke (δ) | Extension (δe): 20 (10 per side) Compression (δc): 50 (25 per side) (※2) | |||||||||||||||||

| Anchor base | K | 60 | 70 | 80 | 100 | 110 | 130 | 150 | 180 | 220 | 280 | 300 | 350 | 400 | 450 | 500 | |||

| J | 100 | 120 | 160 | 180 | 200 | 250 | 300 | 350 | 400 | |||||||||

| H | 100 | 120 | 130 | 140 | 150 | 170 | 200 | 220 | 250 | 300 | 350 | 450 | 500 | 550 | 600 | |||

| I | 3.2 | 4.0 | 4.5 | 25 | ||||||||||||||

| Bolt Hole Diameter – h₂ | 12 | 15 | 19 | 23 | 25 | 27 | 33 | 39 | ||||||||||

| Bolt Thread Nominal Size | M10 | M12 | M16 | M20 | M22 | M24 | M30 | M36 | ||||||||||

| Outer Diameter (D₀) | 58 | 73 | 98 | 110 | 136 | 162 | 212 | 235 | 292 | 333 | 387 | 422 | 470 | 517 | 567 | |||

| Mass (kg) | 5 | 6 | 8 | 8.5 | 11 | 14 | 17 | 22 | 35 | 46 | 66 | 96 | 225 | 271 | 325 | 390 | 442 | |

Note (※2):

Compression δc: 70 mm (35 mm per side) is also available (Model JOB43L, nominal diameter 20–250. This is not a JIS standard product).

Supplement 1:

The value δ is calculated by subtracting the minimum face-to-face length from the maximum. This method is used especially when no strict dimensional specification is required.

Supplement 2:

After the hydraulic pressure test, be sure to remove both the fixing bolts and plates for nominal diameters 20–250, and the fixing bolts for diameters 300–500.