Fushiman Co.

Fushiman MB14 type check valve

Manufacturer: Fushiman Co.,LTD.

Model: MB14

| Model | Nominal diameter | Fluid | Maximum Operating Pressure | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

| MB14 | 15–50 | Steam Gas Liquid | 1.3 MPa | 250°C | Brass | Screw in |

Compact and lightweight — installation orientation is optional.

Features

- Installation direction is optional

It can be mounted vertically, horizontally, or on sloped piping, making it highly convenient. - Quick-closing valve

The valve closes quickly before backflow occurs, thanks to a structure that applies closing force with a spring. - Opens at low differential pressure

Opens at a low differential pressure of 1.5–2.0 kPa. - Lightweight and compact

- Minimal seat leakage

Leakage is extremely minimal.

Specifications

| Type | Threaded Type Spring-Loaded Lift Check Valve | |||

| Model | MB14 | |||

| Type of Disc Contact Surface | Metal Seat | |||

| Applicable Fluid | Applicable Fluids: Steam, air, gas, mineral oil, etc. (¹) | |||

| Maximum Operating Pressure (MPa) | 1.6 | 1.4 | 1.3 | |

| Maximum Operating Temperature (°C) | 120 | 200 | 250 | |

| Material | Disc | Stainless Steel | ||

| Valve Body & Seat (Integral) | Brass | |||

| Spring | Stainless Steel | |||

| Spring Retainer | Stainless Steel | |||

| Opening Pressure | 1.5~2.0kPa | |||

Note (¹): Not suitable for use with water as the fluid.

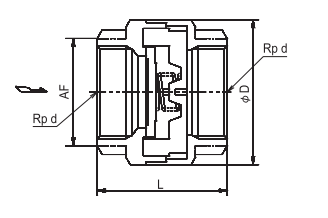

Structure and Dimensions

| Pipe Connection | JIS Parallel Pipe Thread (Rp) | ||||||

| Nominal Diameter | 15 | 20 | 25 | 32 | 40 | 50 | |

| Dimensions | d | ½ | ¾ | 1 | 1¼ | 1½ | 2 |

| L | 49 | 49 | 61 | 61 | 72 | 72 | |

| D | 39 | 39 | 60.5 | 60.5 | 80 | 80 | |

| AF | 30 | 30 | 46 | 46 | 65 | 65 | |

| Cv Value | 4.8 | 4.8 | 13 | 13 | 36 | 36 | |

| Weight | 0.23 | 0.18 | 0.65 | 0.49 | 1.24 | 0.94 | |

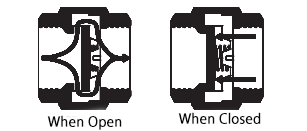

Operation

When fluid flows, the pressure pushes the valve open.

When the fluid flow stops, the spring’s closing force activates, and the valve closes before backflow can occur.

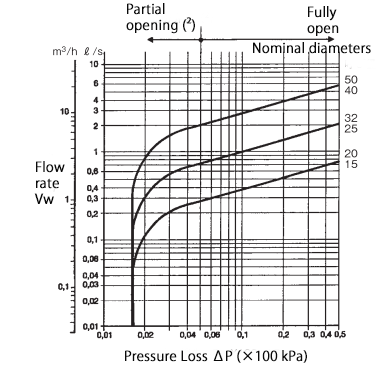

Pressure Loss

- The graph lines represent fluid with a specific gravity of 1 at 20°C.

- To calculate the pressure loss for other fluids, use the following formula to determine the equivalent water flow rate, then refer to the graph:

Vw = V × ρ / 1000

Vw: Equivalent water flow rate (ℓ/s or m³/h)

ρ: Fluid density (operating) (kg/m³)

V: Actual flow rate (operating) (ℓ/s or m³/h) - The graph is based on horizontal piping.

- In vertical piping, there may be slight differences before the valve is fully open. Once fully open (normal flow condition), the behavior is the same as in horizontal piping.

Note (²):

When pressure loss ΔP is 5 kPa or lower, chattering may occur, so please do not use under such conditions.