Fushiman Co.

Fushiman PMD31 Pressure Reducing Valves

Manufacturer: Fushiman Co.,LTD.

Model: PMD31

| Model | Nominal Diameter | Primary Pressure | Secondary Pressure Range | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

| PMD31 | 15〜150 | MAX. 1.0MPa | 0.035~0.7MPa | 80℃ | FC, SCPH, SCS | Flange |

- The direct-acting pressure reducing valve ensures stable operation.

- Since it adopts a primary pressure balance method, the secondary pressure is hardly affected by fluctuations in the primary pressure.

- The valve body uses synthetic rubber, ensuring good sealing performance when the valve is closed.

- If the flow rate is low, please use the PPD41B-3 type pressure reducing valve (nominal diameter 15–25).

Specifications and Materials

| Fluid | Pressure MPa | Temperature ℃ | Nominal Diameter | Main Component Materials | Pipe Connection | ||||

|---|---|---|---|---|---|---|---|---|---|

| Primary Side | Secondary Side Setting Range | Valve Box Spring Protection Tube | Valve Body Diaphragm | Valve Seat/Liner Guide Bush | Valve Stem | ||||

| Air and Other Non-Corrosive Gases | 0.055 1.0 | 0.035〜0.3 0.2〜0.7 | 0 〜 80 | 15〜25 (1) 32〜80 | Cast Iron | Synthetic Rubber | Bronze | Stainless Steel | Flange JIS 10K Full Face |

| 0.035〜0.3 0.2〜0.55 | 100 | ||||||||

| 0.035〜0.4 | 125-150 | ||||||||

Note (1): Normally, the PPD41B-3 type pressure reducing valve is used (for economic reasons), but if its capacity is insufficient (when it reaches the maximum flow limit), this valve is used instead.

Remarks:

- The valve casing can also be made of cast bronze or stainless steel cast bronze. In this case, ASME Class 150 can also be manufactured.

- The connection parts can be made without rubber or brass if required.

- Products exceeding the secondary pressure setting range can also be manufactured.

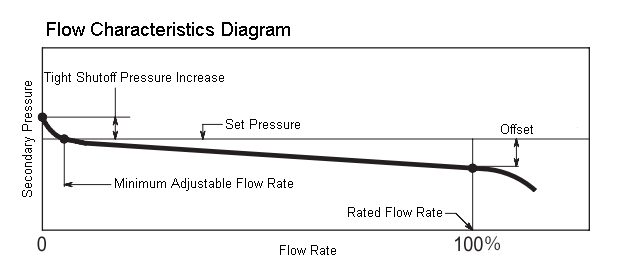

Performance

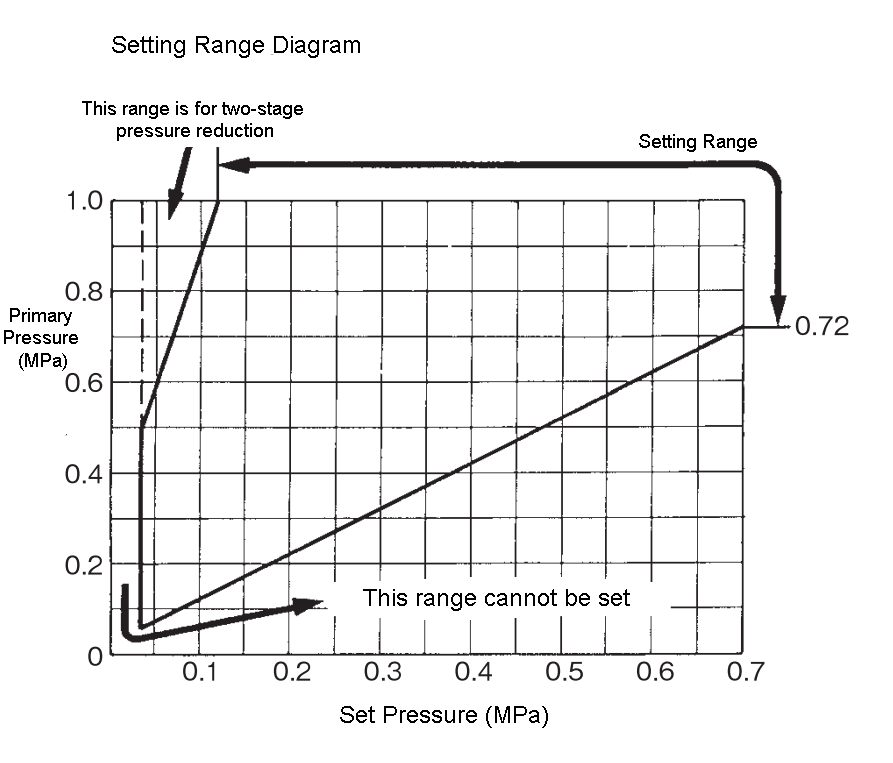

| Reduction Ratio | Refer to the setting range diagram |

|---|---|

| Minimum Settable Differential Pressure | 0.02 MPa |

| Offset | Less than 10% of the maximum set pressure |

| Tight Shutoff Pressure Increase | 0.01–0.02 MPa |

| Minimum Adjustable Flow Rate (Air) (2) | 5–10 m³/h (Standard Conditions) |

| Seat Leakage | Less than 0.01% of the rated flow rate |

Note (2): For gases other than air, divide by √G (where G is the specific gravity of the gas, with air as 1).

Cv Value

| Nominal Diameter | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cv | 1.8 | 2.6 | 3.9 | 6.3 | 8.3 | 13 | 21 | 29 | 50 | 76 | 109 |

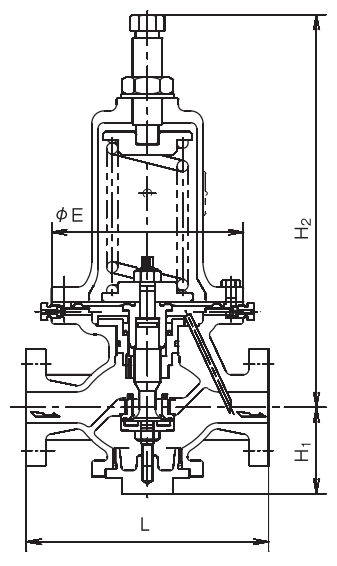

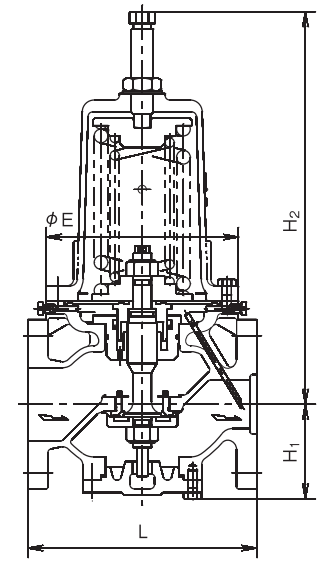

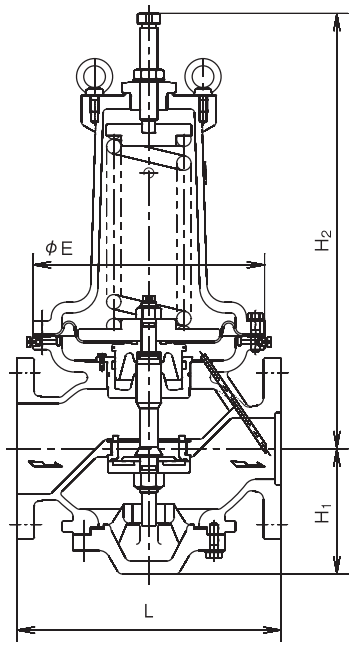

Structure and Dimensions

| Nominal Diameter 15–50 | Nominal Diameter 65–100 | Nominal Diameter 125・150 |

|---|---|---|

|  |  |

Dimensions and Mass

(mm, kg)

| Nominal Diameter | Valve Body: Cast Iron | Valve Body: Cast Bronze or Stainless Steel Cast Bronze | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L | H1 | H2 | E | Mass | L | H1 | H2 | E | Mass | |

| 15 | 196 | 70 | 318 | 155 | 12 | 206 | 70 | 318 | 155 | 16 |

| 20-25 | 200 | 70 | 318 | 155 | 13 | 210 | 70 | 318 | 155 | 17 |

| 32 | 175 | 70 | 318 | 155 | 14 | 220 | 70 | 318 | 155 | 18 |

| 40 | 190 | 80 | 328 | 155 | 16 | 220 | 80 | 328 | 155 | 21 |

| 50 | 195 | 80 | 328 | 155 | 17 | 225 | 80 | 328 | 155 | 22 |

| 65 | 230 | 104 | 429 | 210 | 34 | 280 | 109 | 429 | 210 | 38 |

| 80 | 250 | 104 | 429 | 210 | 35 | 280 | 109 | 429 | 210 | 39 |

| 100 | 290 | 127 | 466 | 250 | 58 | 330 | 121 | 471 | 250 | 65 |

| 125 | 365 | 174 | 612 | 320 | 98 | 380 | 174 | 612 | 320 | 114 |

| 150 | 415 | 207 | 792 | 380 | 159 | 470 | 207 | 792 | 380 | 170 |

Disassembly and Maintenance Space Required

(mm)

| Nominal Diameter | Upward from Pipe Center | Downward from Pipe Center |

|---|---|---|

| 15〜32 | 470 | 190 |

| 40-50 | 480 | 200 |

| 65-80 | 590 | 340 |

| 100 | 650 | 400 |

| 125 | 930 | 450 |

| 150 | 1220 | 550 |