Fushiman Co.

Fushiman PPD41B-3 Pressure Reducing Valves For Liquids

Manufacturer: Fushiman Co.,LTD.

Model: PPD41B-3

| Model | Nominal Diameter | Primary Pressure | Secondary Side Setting Range | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

| PPD41B-3 | 15〜25 | MAX. 1.0MPa | 0.03~0.7MPa | 80℃ | CAC,SCS | Flange, Threaded |

- The valve body adopts a secondary pressure balance method, so the secondary-side pressure is hardly affected by fluctuations in primary-side pressure.

- The valve body is equipped with synthetic rubber, which provides excellent sealing when the valve is closed.

- A built-in strainer (equivalent to 80-mesh) is included.

- For water applications, please use the P100-3Y type pressure reducing valve.

- Install upright on horizontal piping.

Specifications and Materials

| Fluid | Pressure (MPa) | Temperature (°C) | Main Component Materials | Pipe Connection | |||||

|---|---|---|---|---|---|---|---|---|---|

| Primary Side | Secondary Side Setting Range | Valve Body | Lower Cover | Spring Protector | Valve | Diaphragm | |||

| Oil and Other Non-Corrosive Liquids | 0.05 – 1.0 | 0.03 – 0.15 0.1 – 0.7 | 0 – 80 | Bronze | Bronze | Ductile Cast Iron | Stainless Steel and Synthetic Rubber | Synthetic Rubber | JIS Rc Threaded Type |

| Cast Stainless Steel | Stainless Steel | ||||||||

| Cast Stainless Steel | Stainless Steel | Stainless Steel and Teflon | Teflon-Coated Synthetic Rubber | JIS 10K Full-Face Flange | |||||

- Note : For water applications, please use the P100-3Y type pressure reducing valve. It is more economical.

- Remark : If the valve body is made of cast stainless steel, it can also be manufactured to ASME Class 150 standards.

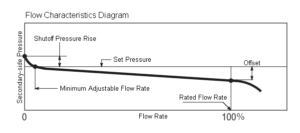

Performance

| Minimum Set Differential Pressure | 0.02MPa |

|---|---|

| Shutoff Pressure Rise | 0.02 MPa or less (For Teflon valve body: 0.03 MPa or less) |

| Offset | 10% or less of the maximum set pressure (Minimum value: 0.05 MPa) |

| Minimum Adjustable Flow Rate (Water)(2) | 1 ℓ/min (For Teflon valve body: 2 ℓ/min) |

| Valve Seat Leakage | 0.01% or less of the rated flow (For Teflon valve body: 0.05% or less) |

| Maximum Usable Viscosity | 200 mm²/s (at operating temperature) (3) |

(2) For fluids other than water, divide by √γ (where γ is the specific gravity of the fluid, with 4°C water as 1).

(3) If the fluid’s viscosity exceeds 20 mm²/s at the operating temperature, flow rate correction is required.

Cv Value

| Nominal Diameter | 15 | 20 | 25 |

|---|---|---|---|

| Cv Value | 1.8 | 2.6 | 3.9 |

| Maximum Flow Rate (Water) ℓ/min (4) | 30 | 55 | 90 |

Note (4):

For fluids other than water, divide by √γ (where γ is the specific gravity of the fluid, with water as 1).

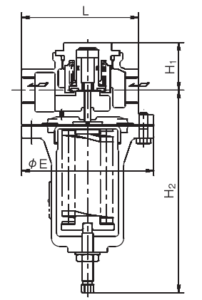

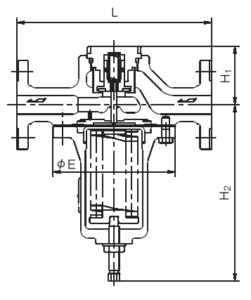

Structure and Dimensions

| Valve Body: Bronze / Cast Stainless Steel | Valve Body: Cast Stainless Steel |

|---|---|

|  |

Dimensions and Mass

(mm, kg)

| Material & Type | Nominal Diameter | Main Dimensions | Mass | |||

|---|---|---|---|---|---|---|

| L | H1 | H2 | E | |||

| Bronze Threaded Type | 15 | 85 | 43 | 168 | 100 | 2.8 |

| 20 | 115 | 47 | 222 | 130 | 5.5 | |

| 25 | 115 | 47 | 222 | 130 | 5.5 | |

| Cast Stainless Steel Threaded Type | 15 | 135 | 49 | 224 | 130 | 6.8 |

| 20 | 135 | 49 | 224 | 130 | 6.8 | |

| 25 | 135 | 49 | 224 | 130 | 6.7 | |

| Cast Stainless Steel Flange JIS 10K | 15 | 207 | 63 | 210 | 130 | 8.3 |

| 20 | 211 | 63 | 210 | 130 | 8.7 | |

| 25 | 211 | 63 | 210 | 130 | 9.3 | |