Fushiman Co.

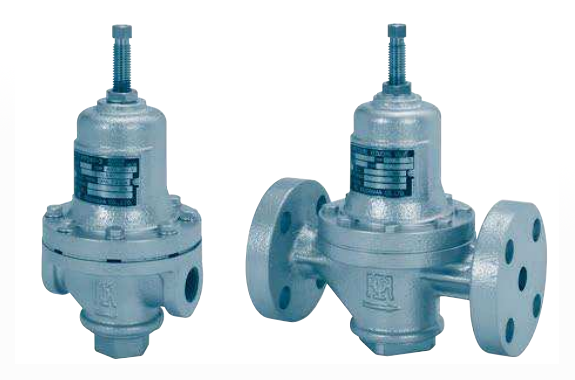

Fushiman PPD41L-3 Pressure Reducing Valves

Manufacturer: Fushiman Co.,LTD.

Model: PPD41L-3

| Model | Nominal Diameter | Primary Pressure | Secondary Pressure Range | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

| PPD41L-3 | 15〜25 | MAX. 0.5MPa | 0.01~0.15MPa | 80℃ | FCD,SCPH,SCS | Threaded, Flange |

- PPD41B-3 type pressure reducing valve is for low-pressure applications.

- The valve is equipped with synthetic rubber, ensuring good sealing when closed.

- If the valve body is made of stainless steel casting, a built-in strainer is included (equivalent to 80 mesh).

- If the capacity is insufficient, please use the PMD31L type pressure reducing valve.

- Ideal for high-precision pressure control, such as in combustion burners.

Specifications and Materials

| Fluid | Pressure MPa | Temperature ℃ | Main Component Materials | Pipe Connection | |||||

|---|---|---|---|---|---|---|---|---|---|

| Primary Side | Secondary Side Setting Range | Valve Box | Lower Cover | Spring Protection Tube | Valve Body & Stem | Diaphragm | |||

| Air and Other Non-Corrosive Gases | 0.03 – 0.5 | 0.01 – 0.05, 0.03 – 0.15 | 0 – 80 | Ductile Cast Iron | Bronze | Ductile Cast Iron | Stainless Steel (Valve Contact Surface with Synthetic Rubber Coating) | Synthetic Rubber | JIS Rc Threaded Type |

| Ductile Cast Iron | Bronze | Flange JIS 10K Full Face | |||||||

| Cast Steel | Stainless Steel | ||||||||

| Stainless Steel Cast Steel | |||||||||

Note: The valve body can also be made of cast bronze or stainless steel cast bronze according to ASME Class 150.

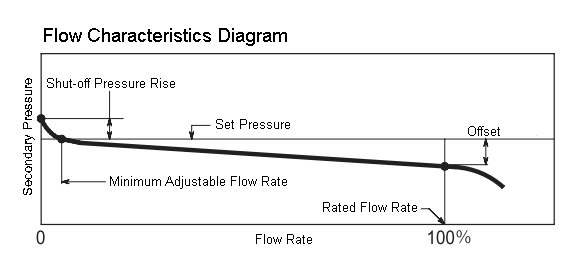

Performance

| Minimum Differential Pressure Setting | 0.02 MPa |

|---|---|

| Offset | Approx. 10% of Maximum Set Pressure (Minimum Value 0.01 MPa) |

| Shut-off Pressure Rise | Approx. 5% of Maximum Set Pressure |

| Minimum Adjustable Flow Rate (Air) | Approx. 0.3 m³/h (Standard Condition) |

| Valve Seat Leakage | Below 0.01% of Rated Flow |

| Cv Value | 1.8 |

| Maximum Flow Rate | Nominal Diameter 15: 20 m³/h (Standard Condition), Nominal Diameter 20・25: 35 m³/h (Standard Condition) |

Structure and Dimensions

Dimensions and Mass

(mm, kg)

| Material | Nominal Diameter | Main Dimensions | Mass | Pipe Connection | |||

|---|---|---|---|---|---|---|---|

| L | H1 | H2 | E | ||||

| Ductile Cast Iron | 15 | 95 | 49 | 165 | 100 | 2.6 | JIS Rc Threaded Type |

| 20 | 130 | 61 | 222 | 130 | 5.8 | ||

| 25 | 130 | 61 | 222 | 130 | 5.8 | ||

| Ductile Cast Iron | 15 | 170 | 54 | 161 | 100 | 4.6 | Flange JIS 10K Full Face |

| 20 | 215 | 65 | 218 | 130 | 7.9 | ||

| 25 | 215 | 65 | 218 | 130 | 8.9 | ||

| Cast Steel | 15 | 207 | 69 | 213 | 130 | 8.3 | Flange JIS 10K Full Face |

| 20 | 211 | 69 | 213 | 130 | 8.7 | ||

| 25 | 211 | 69 | 213 | 130 | 9.3 | ||

| Stainless Steel Cast Steel | 15 | 207 | 63 | 210 | 130 | 8.3 | Flange JIS 10K Full Face |

| 20 | 211 | 63 | 210 | 130 | 8.7 | ||

| 25 | 211 | 63 | 210 | 130 | 9.3 | ||