- 42-type series pilot-operated pressure reducing valve (PPD48 type).

- Small and low-capacity pressure reducing valve, can be used independently.

- The valve seat made of synthetic rubber ensures good sealing when the valve is closed.

- Suitable for high pressure, high differential pressure, and low-pressure calibration.

- Can be installed in horizontal, vertical, or any angled position.

- The PPD48 pressure reducing valve is also available as an approved product for gas and high-pressure gas equipment (Valve body: stainless steel or cast steel).

Specifications and Materials

| Model | Fluid | Pressure (MPa) | Temperature (°C) | Main Material Components | Connection Size & Standard | ||||||

| Primary Side | Secondary Side Setting Range | Valve Body | Spring Protection Tube | Valve Seat | Valve Seat | Bottom Cover | Diaphragm | ||||

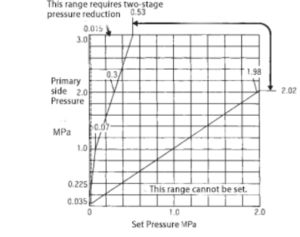

| PPD48 | Water, Oil, Other Non-Corrosive Liquids | 0.035~2.0 | 0.015~0.07 (A) 0.05~0.3 (B) 0.2~0.8 (C) 0.7~1.4 (D) 1.2~1.98 (E) | 0~80 | Bronze | Cast Iron or Stainless Steel | Bronze/Stainless Steel (Synthetic Rubber Contact Surface) | Bronze (Integrated with Valve Body) | Bronze | Synthetic Rubber | 10-JIS Rc Threaded Type |

| Cast Stainless Steel | Stainless Steel (Synthetic Rubber Contact Surface) | Cast Stainless Steel (Integrated with Valve Body) | Stainless Steel | 10, 15-JIS Rc Threaded Type | |||||||

| 15–25 JIS 20K Flange Flat Seat | |||||||||||

| 0.035~3.0 | Stainless Steel (Fluorine Contact Surface) | 10-JIS Rc Threaded Type | |||||||||

| PPD48F | 0.035~2.0 | Bronze | Cast Iron | Bronze/Stainless Steel (Synthetic Rubber Contact Surface) | Bronze (Integrated with Valve Body) | Bronze | 15, 20-JIS Rc Threaded Type | ||||

| 0.035~2.4 | Cast Stainless Steel | Stainless Steel (Synthetic Rubber Contact Surface) | Cast Stainless Steel (Integrated with Valve Body) | Stainless Steel | 20, 25 JIS 20K Flange Flat Seat | ||||||

Note (1): A to E correspond to the designated line diagram symbols in the nominal diameter selection diagram on the next page, and the set pressure range varies accordingly.

Performance

Please select the appropriate nominal diameter based on the nominal diameter selection diagram on the next page.

If the viscosity exceeds 20 mm²/s, input the flow rate after viscosity correction into the nominal diameter selection diagram and choose accordingly.

When the primary-side pressure and set pressure are constant but there is a fluctuation range, select the nominal diameter based on the primary-side pressure and set pressure where the differential pressure is minimized. If the differential pressure is less than 0.1 MPa, add the offset to the differential pressure before selecting the nominal diameter. Selecting an excessively large pressure reducing valve is not cost-effective.

Viscosity Correction

To account for viscosity in calculations, first determine the Cv value without considering viscosity. Next, calculate the viscosity index RRR using formula ② and obtain the correction factor ααα from the diagram below. Multiply ααα by the flow rate QQQ to obtain the corrected flow rate QQQ. Use this corrected QQQ with the diagram on the next page to select the appropriate nominal diameter.

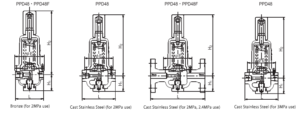

Structure and Dimensions

Dimensions and Weight

| Model | Specification | Nominal Diameter | L (mm) | H₁ (mm) | H₂ (mm) | E (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| PPD48 | Bronze (for 2.0MPa) | Threaded 10 | 76 | 44 | – | – | 2.4 |

| Stainless Steel Casting (for 2.0MPa) | Threaded 10 | 94 | 44 | – | – | 3.5 | |

| Threaded 15 | 130 | 44 | 173 | 80 | 3.6 | ||

| Flange 15–25 | 155 | 44 | – | – | 5.7 | ||

| PPD48 | Stainless Steel Casting (for 3.0MPa) | Threaded 10 | 94 | 44 | – | – | 3.5 |

| PPD48F | Bronze (for 2.0MPa) | Threaded 15・20 | 110 | 61 | 212 | 120 | 5.2 |

| Stainless Steel Casting (for 2.4MPa) | Flange 20・25 | 195 | – | – | – | 9.1 |