Fushiman Co.

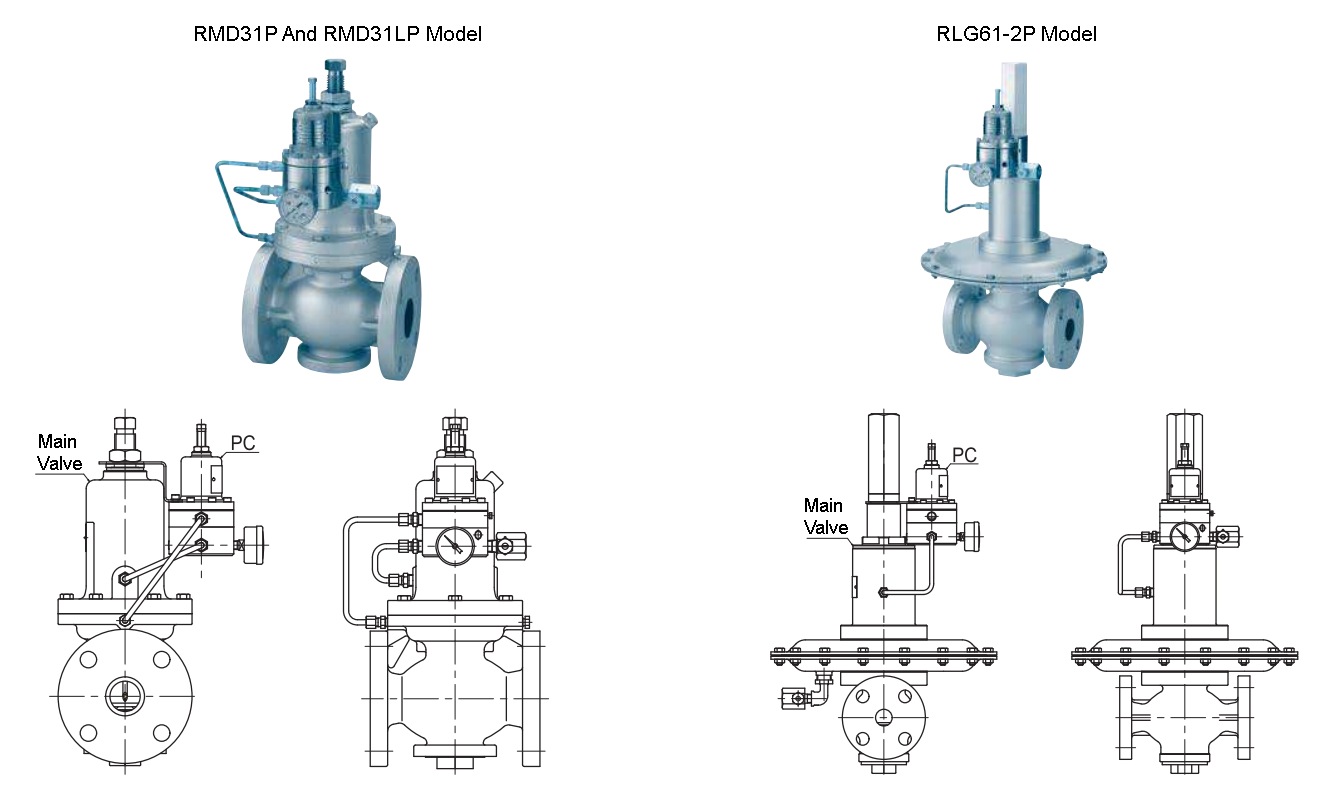

Fushiman RMD31P/LP And RLG61-2P Hybrid Back Pressure Regulating Valves

Manufacturer: Fushiman Co.,LTD.

Model: RMD31P/LP And RLG61-2P

RMD31P Type Back Pressure Valve for Gas

| Model | Nominal Diameter | Primary Pressure Setting Range | Max Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|

| RMD31P | 15~100 | 0.035~0.7MPa | 80℃ | FC | Flange |

RMD31LP Type Back Pressure Valve for Gas

| Model | Nominal Diameter | Primary Pressure Setting Range | Max Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|

| RMD31LP | 15~100 | 0.01~0.05MPa | 80℃ | FC | Flange |

RLG61-2P Type Back Pressure Valve for Gas

| Model | Nominal Diameter | Primary Pressure Setting Range | Max Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|

| RLG61-2P | 15〜50 | 0.5~20kPa | 80℃ | FC | Flange |

RMD31P Type Back Pressure Valve for Liquid

| Model | Nominal Diameter | Primary Pressure Setting Range | Max Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|

| RMD31P | 15〜100 | 0.035~0.7MPa | 80℃ | FC | Flange |

New Product

- Maintains the characteristics of a self-operated valve that accurately controls load fluctuations while achieving an offset comparable to other valves.

- Compared to conventional products, an increase in nominal flow rate (Cv value) can be expected. (Note: The Cv value depends on factors such as pipe flow velocity and remains the same for certain types and sizes as previous products.)

- Can be installed on existing valves, allowing for an easy performance upgrade.

- Useful when replacing existing self-operated valves while maintaining tuning accuracy in large-scale systems.

- Versatile, supporting both low-pressure applications and compressed air control via a pressure-reducing valve.

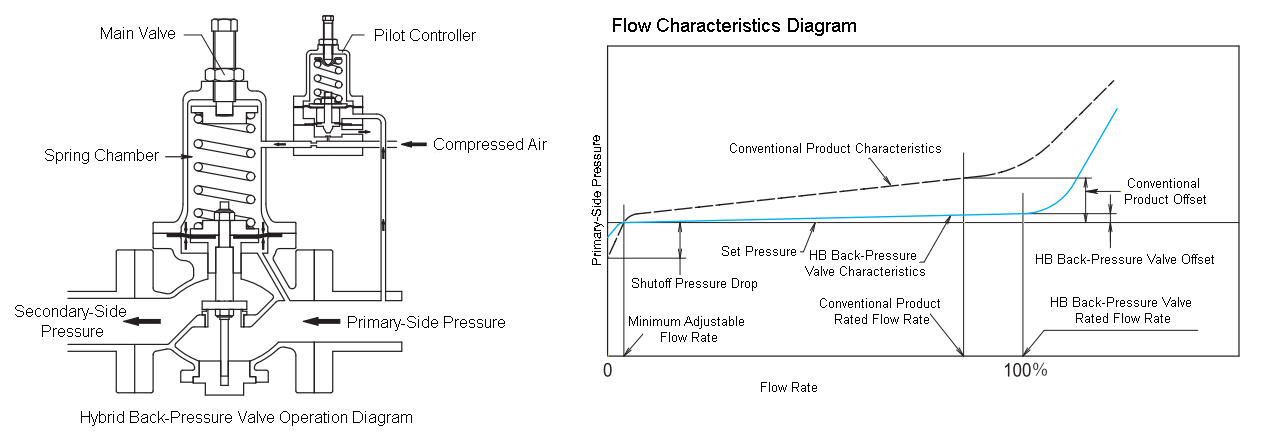

The Hybrid Back-Pressure Valve achieves high precision comparable to other control valves by simply adding a newly designed pilot controller to a standard self-operated back-pressure valve.

A conventional self-operated back-pressure valve may have offset issues and insufficient adjustment accuracy, and control using other types of regulating valves for primary-side pressure control may complicate system configurations.

For applications requiring high-precision primary pressure control with a simpler system setup, the Hybrid Back-Pressure Valve is the optimal solution.

1. Type of Equipment

1.1 Hybrid Back-Pressure Valve

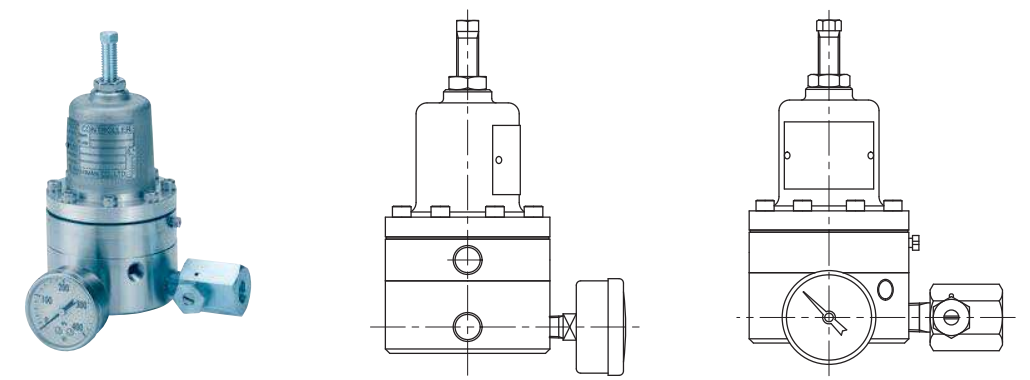

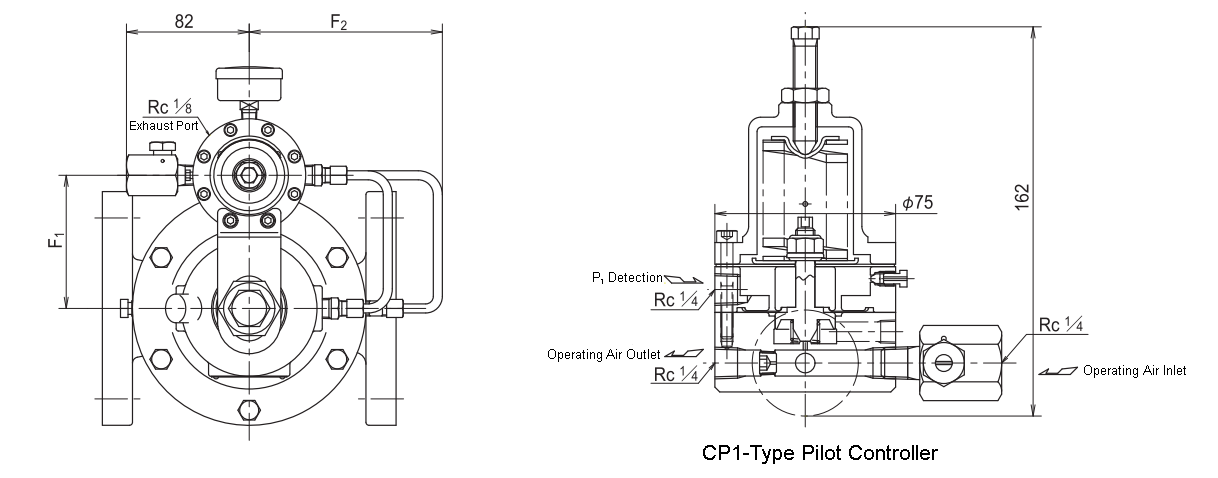

1.2 CP1-Type Pilot Controller (PC)

2. Operation Description

The Hybrid (HB) Back-Pressure Valve consists of two components:

- The main valve, which controls pressure.

- The pilot controller (PC), which adjusts the operating fluid based on changes in primary-side pressure.

- The pilot controller is supplied with an operating fluid, such as compressed air, and its outlet is connected to the spring chamber of the main valve.

The main valve automatically adjusts the valve opening in response to primary-side pressure, similar to a standard back-pressure valve.

- However, the spring force varies depending on the valve opening (large when fully open, small when slightly open), which causes offset.

The pilot controller operates as follows:

- When primary pressure is high, it opens and releases the operating fluid externally.

- When primary pressure is low, it closes and sends the operating fluid to the spring chamber.

- The main valve and the pilot controller operate almost simultaneously, ensuring that primary-side pressure remains stable even when load fluctuations occur.

3. Specifications and Materials

| Hybrid Back-Pressure Valve Model | RMD31P | RMD31LP | RLG61-2P | |

|---|---|---|---|---|

| Main Valve Section | Model | RMD31 | RMD31L | RLG61-2 |

| Fluid | Gas & Liquid | Gas | ||

| Nominal Diameter | 15–100 | 15–50 | ||

| Set Pressure Range | 15–80A: 0.035–0.3, 0.2–0.7 MPa 100A: 0.035–0.3, 0.2–0.55 MPa | 10–50 kPa | 0.5–1.4, 1.2–3.3, 3.0–8.0, 7.0–20 kPa | |

| Temperature | 0–80°C | |||

| Major Materials | Refer to the catalog for main valve materials. | |||

| PC Section | Operating Fluid | Air | ||

| Operating Pressure | 140–250 kPa | 100 kPa | 20–40 kPa | |

| Air Consumption | Approx. 200 ℓ/h (Standard Condition) | Approx. 40 ℓ/h (Standard Condition) | ||

| Connection Port | JIS Rc 1/4 (Threaded) | |||

| Major Materials | Body & Valve: Stainless Steel, Spring Protection Tube: Aluminum Alloy, Diaphragm: Synthetic Rubber, Orifice Valve & Piping: Copper Alloy | |||

Note (1): The operating pressure varies depending on the set pressure.

4. Performance and Cv Value

| Hybrid Back-Pressure Valve Model | RMD31P (RMD31LP) | RLG61-2P | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Diameter | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 15 | 20 | 25 | 32 | 40 | 50 | |

| Cv Value | 4.5 | 4.5 | 4.5 | 7.0 | 10.1 | 18 | 28.1 | 35 | 55 | 1.8 | 2.6 | 3.9 | 6.3 | 8.3 | 13 | |

| Performance | Minimum Differential Pressure | 10 kPa (10 kPa) | 0.5 kPa | |||||||||||||

| Offset | 30 kPa or less (3 kPa or less) | 30 kPa or less (3 kPa or less) | 0.1 kPa or less | |||||||||||||

| Shutoff Pressure Drop | 10 kPa or less (3 kPa or less) | 10 kPa or less (5 kPa or less) | 0.2 kPa or less | |||||||||||||

| Minimum Adjustable Flow Rate | Refer to the main valve catalog. | |||||||||||||||

| Seat Leakage | 0.01% or less of the rated valve flow | |||||||||||||||

Note (2): The values may vary depending on the set pressure and the piping conditions before and after the valve.

Note (3): The values may increase depending on the main valve settings.

5. Structure, Dimensions, and Mass

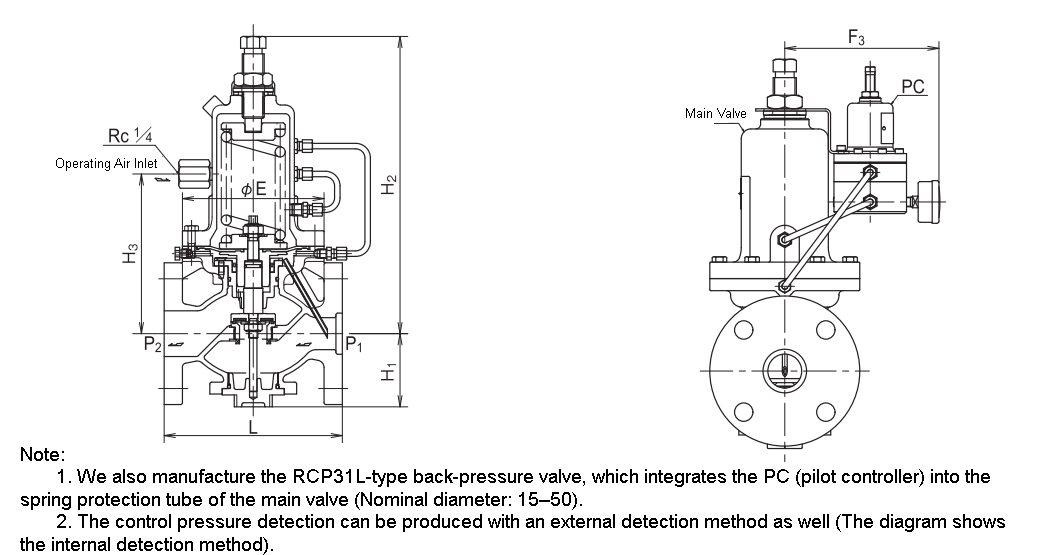

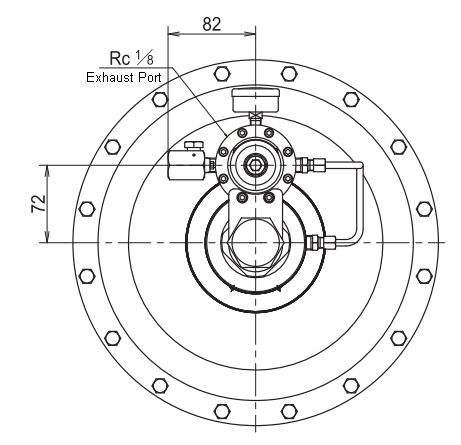

5.1 Structure, Dimensions, and Mass of RMD31P and RMD31LP Back-Pressure Valves

Dimensions and Mass (mm, kg)

| Nominal Diameter | L | Hi | h2 | h3 | E | Fi | f2 | f3 | Weight | Main Valve: Pipe Connection, Valve Body Material: Cast Iron | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RMD31P | RMD31LP | ||||||||||

| 15 | 196 | 70 | 317 | 363 | 165 | 155 | 88 | 128 | 159 | 15 | Flange Type JIS10K Full Face |

| 20 | 200 | 70 | 317 | 363 | 165 | 155 | 88 | 128 | 159 | 16 | |

| 25 | 200 | 70 | 317 | 363 | 165 | 155 | 88 | 128 | 159 | 16 | |

| 32 | 175 | 70 | 317 | 363 | 165 | 155 | 88 | 128 | 159 | 17 | |

| 40 | 190 | 80 | 325 | 371 | 175 | 155 | 88 | 128 | 159 | 19 | |

| 50 | 195 | 80 | 325 | 371 | 175 | 155 | 88 | 128 | 159 | 20 | |

| 65 | 230 | 104 | 425 | 484 | 254 | 210 | 109 | 156 | 180 | 37 | |

| 80 | 250 | 104 | 425 | 484 | 254 | 210 | 109 | 156 | 180 | 38 | |

| 100 | 290 | 127 | 460 | 533 | 289 | 250 | 126 | 176 | 197 | 61 | |

Note: We also manufacture valve bodies made of cast bronze or cast stainless steel.

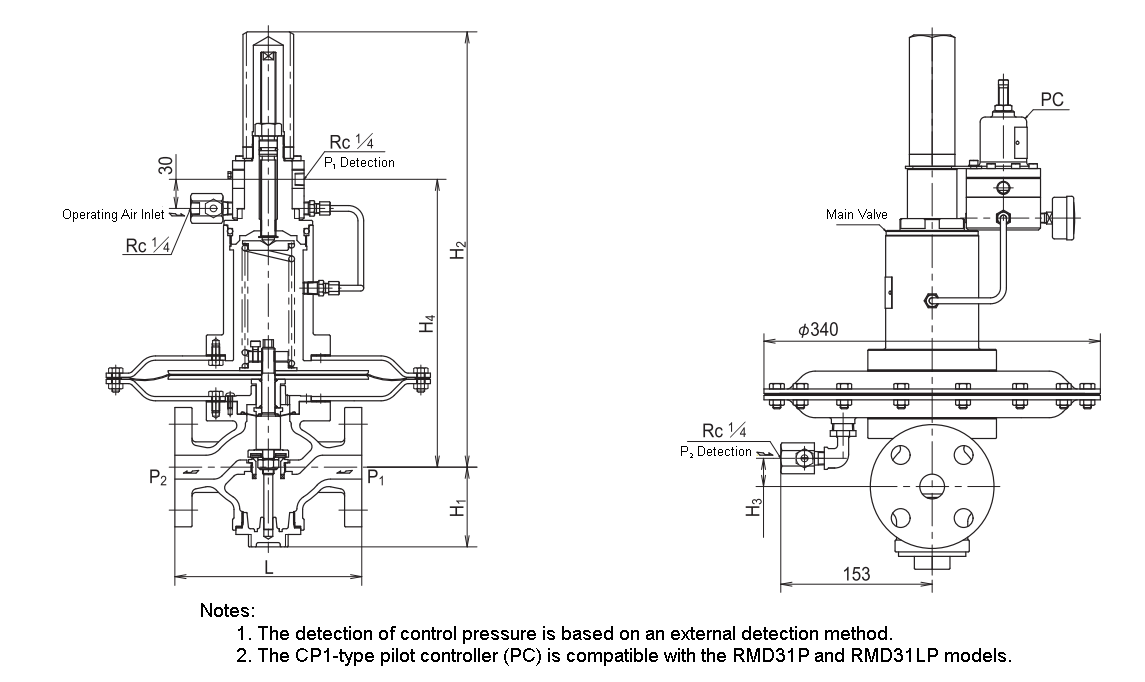

5.2 Structure, Dimensions, and Mass of RLG61-2P Type Back Pressure Valve

Dimensions and Mass (mm, kg)

| Nominal Diameter | L | Hi | h2 | h3 | H4 | Mass | Main Valve: Pipe Connection, Valve Body Material: Cast Iron |

|---|---|---|---|---|---|---|---|

| 15 | 180 | 81 | 451 | 25 | 298 | 23.5 | Flange Type JIS10K Full Face |

| 20 | 185 | 81 | 451 | 25 | 298 | 23.5 | |

| 25 | 196 | 84 | 455 | 30 | 302 | 25 | |

| 32 | 220 | 92 | 478 | 53 | 325 | 28 | |

| 40 | 220 | 92 | 478 | 53 | 325 | 29 | |

| 50 | 230 | 92 | 478 | 53 | 325 | 30 |

Note: The valve body material can be made of cast bronze or stainless steel cast steel.

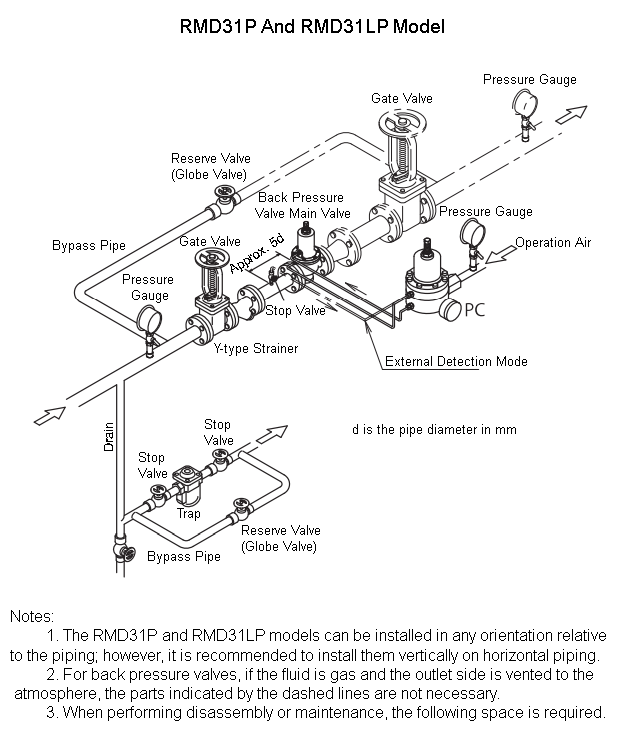

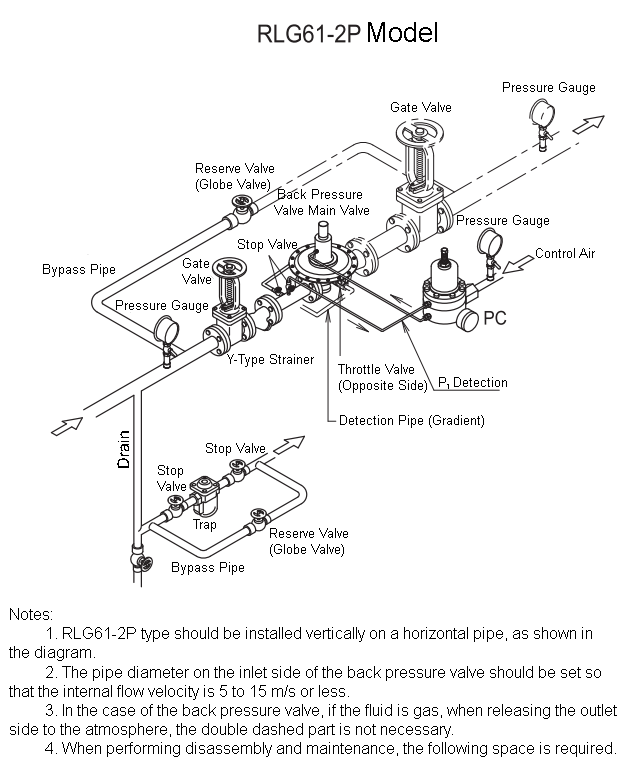

6. Piping Example

(mm)

| Nominal Diameter | 15–32 | 40 • 50 | 65 • 80 | 100 |

|---|---|---|---|---|

| Above Pipe Center | 520 | 530 | 650 | 720 |

| Below Pipe Center | 190 | 200 | 340 | 400 |

(mm)

| Nominal Diameter | 15–50 |

|---|---|

| Above Pipe Center | 520 |

| Below Pipe Center | 190 |

7. Precautions for Use

● Before using, be sure to read the “Instruction Manual” carefully.

● Before connecting the operation air piping, always blow it out to remove dust (scale) and other debris completely.

● The pilot controller (PC) should be supplied with a constant pressure of operating air through a pressure-reducing valve with a filter.

● Ensure that the exhaust port of the pilot controller is not blocked.

● When using the RMD31P model for liquids, make sure to completely discharge the air retained inside at the beginning of water flow.