Fushiman Co.

Fushiman TL10H type temperature control valve

Manufacturer: Fushiman Co.,LTD.

Model: TL10H

| Model | Nominal diameter | Pressure | Temperature setting | Body Material | Connection |

|---|---|---|---|---|---|

| TL10H | 15–50 | Max. 1.0MPa | 10 to 110°C | FCD | Flange (screw-in temperature sensor) |

Features

Compared to conventional bellows-type (single-seat valves), it offers a larger capacity with less seat leakage, and is also compact and lightweight.

The actuator can be easily attached and detached from the valve body, allowing wide-range temperature adjustment with a single actuator and capillary tube.

Designed to be less affected by fluid pressure.

The capillary tube uses a liquid expansion system, so the installation angle is flexible.

The fluid inside the capillary tube and actuator uses water or alcohol-based liquid, so no special disposal by a waste treatment contractor is required.

Main Specifications

| Application & Model Name | For heating use: TL10H Type | |||||

| Temperature Setting Range | 10 to 110°C | Refer to standard temperature setting range | ||||

| Nominal Diameter | 15 | 20 | 25 | 32 | 40 | 50 |

| Valve Type | Single-seat (straight plug) | |||||

| Seat Leakage | Less than 0.05% of rated flow | |||||

| Maximum Operating Pressure of Valve Body (MPa) | 1.0 | 0.7 | ||||

| Valve Body Pipe Connection | Flange JIS 10K full-face | |||||

| Valve Flow Medium | Steam (185°C or lower), hot water | |||||

| Applicable Pressure for Capillary Tube (MPa) | 1.0 MPa or less (external pressure) | |||||

| Capillary Tube Connection Standard | JIS pipe taper thread | |||||

| Capillary Tube Length | Standard length 3 m (up to max. 8 m) | |||||

Note: The ambient temperature around the valve should be (set valve temperature – 10°C) or lower.

Standard Temperature Setting Range

| Type | Temperature Setting Range | Heat Resistance |

|---|---|---|

| Low Temp | 10°C or higher, 70°C or lower | Setting temp +10°C |

| Standard | 50°C or higher, 110°C or lower | Setting temp +15°C* |

* The maximum temperature is 120°C.

Valve Opening/Closing Temperature Difference

| Category | Standard / Low Temp Use |

|---|---|

| CT 3m | 5°C or less |

Materials of Main Components

| Part Name | Material |

|---|---|

| Valve Body | Spheroidal Graphite Cast Iron |

| Upper Cover | Spheroidal Graphite Cast Iron |

| Valve Plug | Stainless Steel |

| Valve Seat | Stainless Steel |

| Spring Cover | Cast Iron |

| Piston Chamber | Brass |

| Capillary Tube (CT) | Copper Tube(2) |

| Capillary Bulb | Stainless Steel Tube |

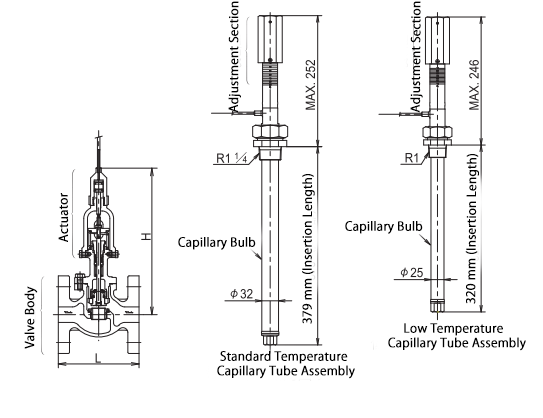

Dimensions, Weight, and Cv Value

| Category | Nominal Diameter (mm) | |||||

|---|---|---|---|---|---|---|

| 15 | 20 | 25 | 32 | 40 | 50 | |

| L (mm) | 120 | 120 | 130 | 150 | 160 | 180 |

| H (mm) | 236 | 236 | 236 | 244 | 244 | 249 |

| Weight (kg) | 7 | 7.5 | 8.5 | 11 | 12 | 14 |

| Cv Value | 3.5 | 3.5 | 5 | 8 | 10 | 16 |

Structure and Dimensions

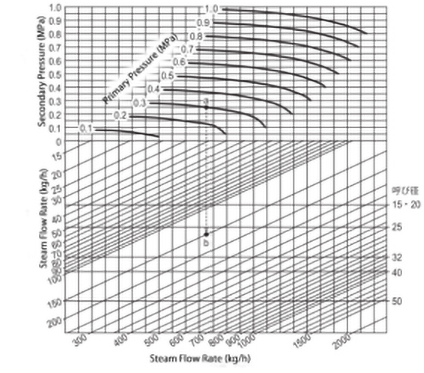

Nominal Diameter Selection (Example)

If you are using superheated steam, please contact us.

Example of using the selection chart

Specifications: Fluid – Saturated steam

Primary side pressure: 0.3 MPa

Flow rate: 150 kg/h

① Assume the allowable valve pressure drop ΔP is 0.05 MPa. Determine the intersection point between the secondary side pressure 0.25 MPa (0.3 – 0.05 MPa) and the primary side pressure 0.3 MPa.

② From intersection point A, draw a vertical line downward and find point B where it intersects with the flow rate of 150 kg/h.

③ Point B falls between nominal diameters 25 and 32, so select the larger one, which is 32.

Notes:

Plan so that the flow velocity at the primary pressure side is 30 m/s or lower.

The allowable valve pressure drop ΔP (pressure difference across the valve) should be 0.2 MPa or less.