Gore (日本ゴア)

GORE 1000 Series Gasket Tape

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: 1000 Series

Overview of 1000 Series

Chemical processors use glass-lined steel pipe and equipment to deal with aggressive media under demanding conditions. Yet the inherent demands of such systems can make it challenging to maintain a tight, lasting seal and prevent leaks that can pose hazards to the equipment, and to the working environment.

GLASS-LINED STEEL SEALING CHALLENGES

- High temperatures

- Alternating system pressures

- Limited gasket loads

- Deviations in flanges / sealing surfaces

GORE GASKET TAPE SERIES 1000

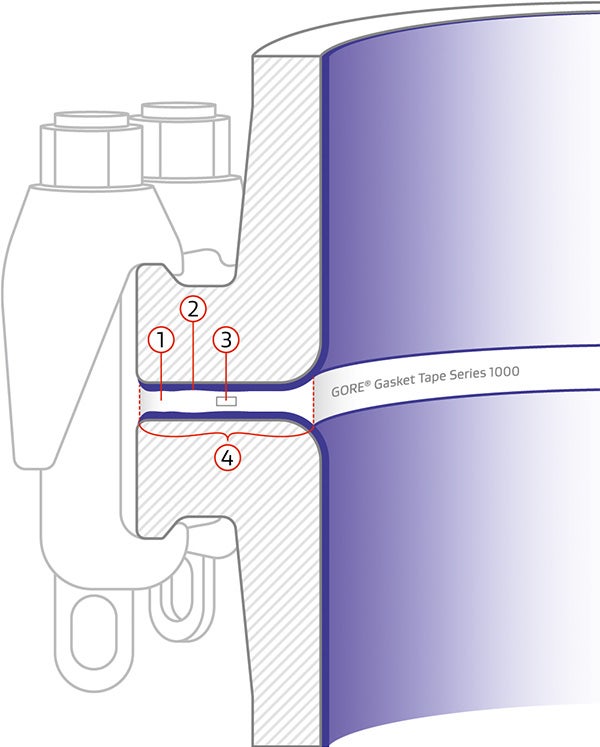

GORE Gasket Tape Series 1000 addresses all the challenges of reliably sealing large glass-lined flanges. Made of 100% expanded PTFE (ePTFE), this highly conformable sealant tape is chemically inert, and highly resistant to creep, cold flow and clamp-force loss. Its proprietary barrier core maintains an extra-tight seal even at low loads.

- Highly creep resistant, to maintain gasket load

- Highly conformable, to seal surface deviations

- Barrier core for extra tightness at low loads

- Chemically-inert 100% ePTFE protects full width of flange

Applications

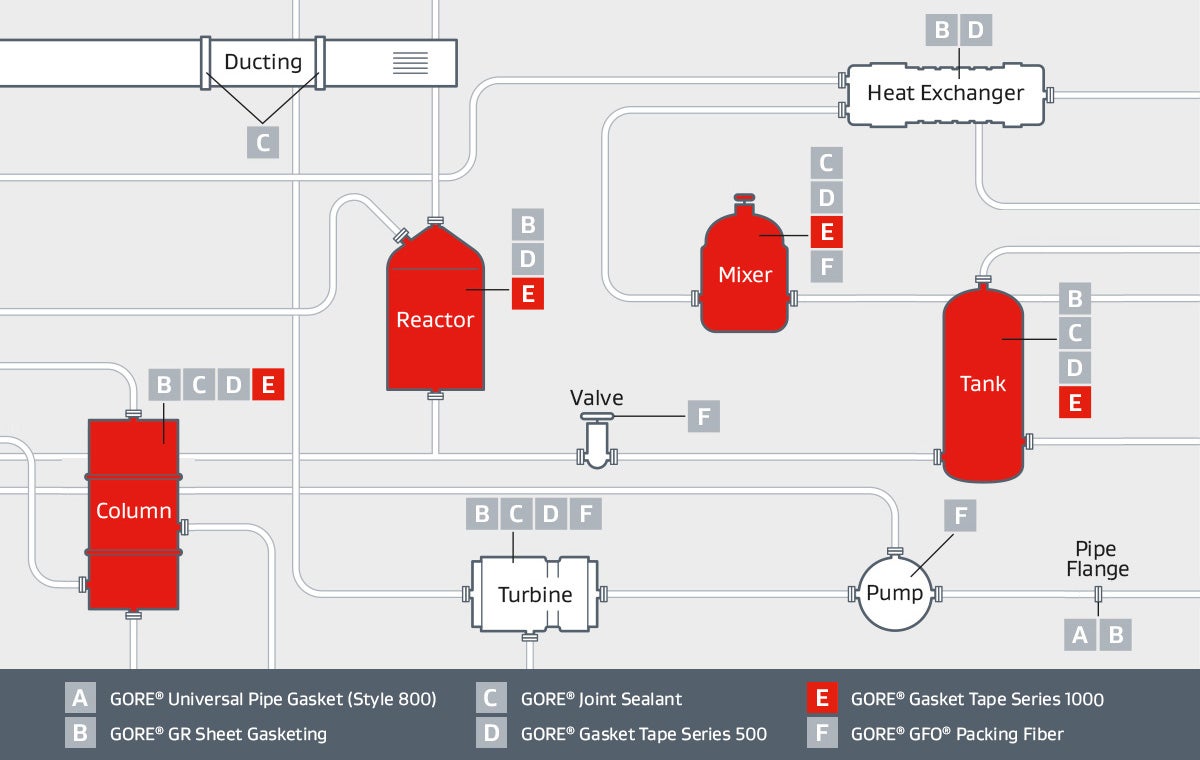

GORE Gasket Tape Series 1000 offers the performance and versatility to reliably seal a range of industrial glass-lined equipment, in diverse applications with harsh process conditions.

- Processes that use highly-aggressive media, for example, in the chemical processing or mining and minerals industries.

- Any glass-lined columns, mixer vessels, or reactor, storage and receiver tanks with glass-lined steel flanges that are large (≥ DN600/ASME 24”) or non-standard.

APPLICATIONS FOR GORE GASKET TAPE SERIES 1000

GORE® Gasket Tape Series 1000 addresses all the challenges of reliably sealing large glass-lined steel flanges.

Performance Benefits

With Gore’s advanced ePTFE material technology and its proprietary barrier core, our Series 1000 gasket tape enables high-performance, high-reliability sealing.

Why consider ePTFE tape

Unique barrier core technology

- Barrier core engineered to amplify the available load.

- Seals more than 10 times tighter than other ePTFE gasket tapes. (Especially important where glass-lined reactor safety is a consideration.)

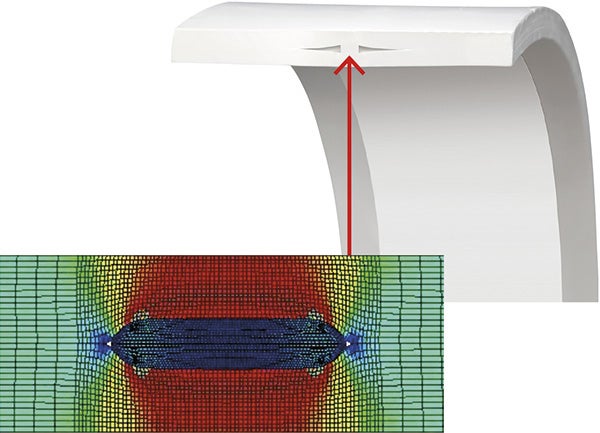

Outstanding conformability to deviations

- Seals deviations even at low gasket stress.

- Easily passes the bubble test, for trouble-free mechanical completion (MC) or start-up.

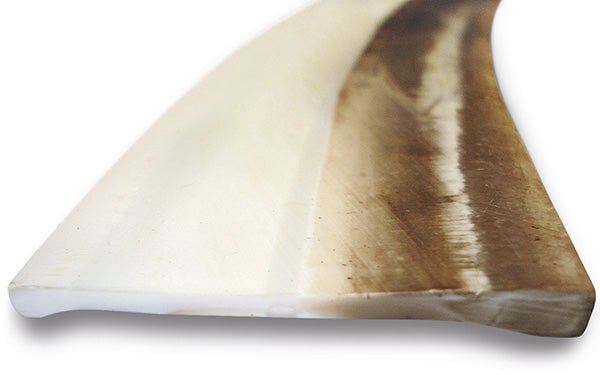

Cross section of GORE® Gasket Tape Series 1000 checked with Finite Element Analysis (FEA) model. Red indicates optimal sealing stress.

Optimal form for easy handling

- Gasket can be customized on-site.

- No fabrication lead-time required.

- Convenient spool format simplifies and speeds handling & transport.

- Adhesive backing enables easy installation in ambient temperatures from 2–50 °C (36–122 °F).

- Faster, less complicated shimming tape technique for larger deviations.

- Reduces inventory costs.

Installation temperature window is effective from hot summer conditions to almost freezing surface temperature.

Reliable and long-term seal

- Barrier core creates a tight seal that impedes even highly-permeating media.

- Provides chemical protection across the full flange width (100% ePTFE).

- Tape is engineered to resist creep and clamp-force loss.

- Allows full use of specification range of the glass-lined steel equipment.

- Enables longer maintenance cycles, as demanded by leading chemical producers.

Cross-section shows how well GORE Gasket Tape Series 1000 endures in challenging conditions with aggressive media.