Gore (日本ゴア)

GORE 7 Series Microwave/RF Assemblies For Civil Aircraft

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: 7 Series

Overview of 7 Series

The aerospace environment routinely exposes microwave/RF assemblies to harsh contaminants such as fuels, oils, and chemicals that can quickly degrade aircraft structures and cause assembly failure in sensitive avionics. In fact, globally more than 75% of microwave/RF assemblies are frequently replaced because of damage during installation or operation according to our independent studies and research. Costs can quickly add up with replacing assemblies, extra labor, and more maintenance and downtime!

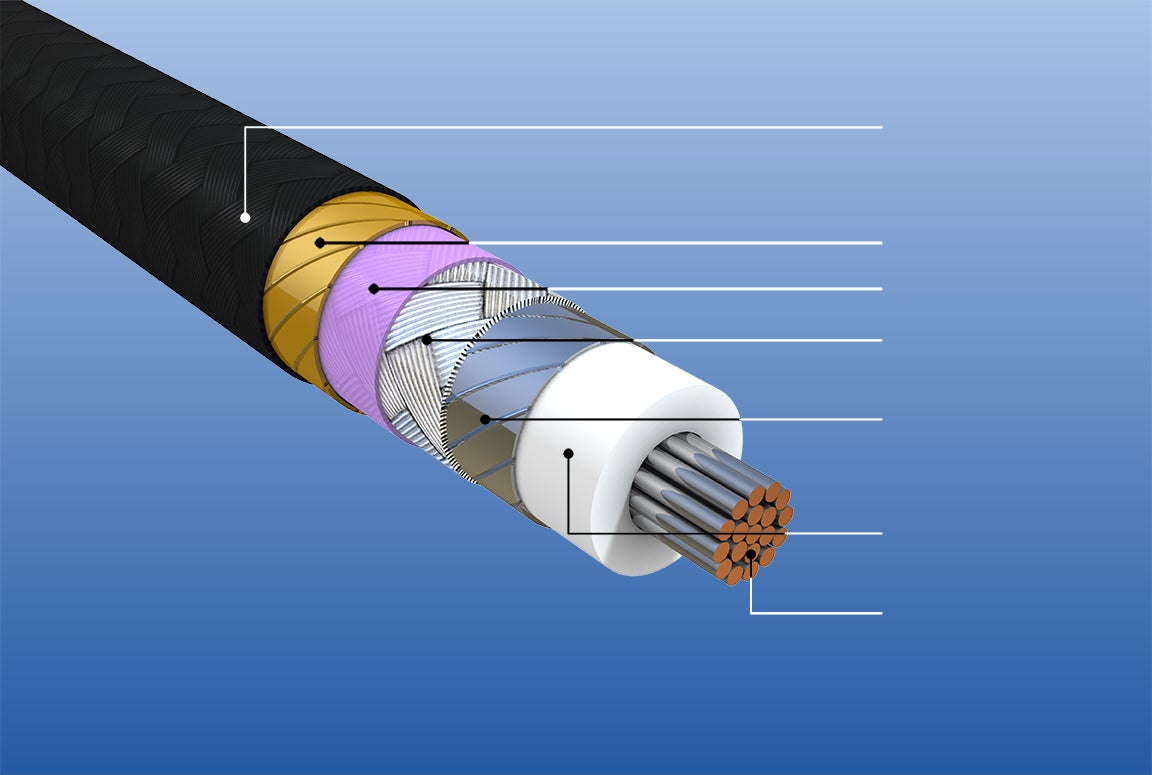

VAPOR-SEALED FOR DURABLE PERFORMANCE

GORE Microwave/RF Assemblies, 7 Series is engineered precisely to prevent the ingress of water vapor, fuel, and other hazardous contaminants. They routinely maintain low insertion/return loss and excellent phase stability at frequencies up to 18 gigahertz (GHz).

Not only that, our robust assemblies provide outstanding shielding effectiveness against electromagnetic interference that can compromise signal integrity and reduce the quality of signal transmission. We also offer robust, low-profile connector options designed specifically to complement assembly performance, minimizing loss and reflection for optimized signal transmission.

When it comes to installation, aircraft maintainers will find it much easier to route our assemblies in confined areas because they’re smaller and more flexible with a tighter bend radius. You can be confident that our 7 Series won’t break or fail during routing, like other standard assemblies that are more rigid.

The 7 Series is thoroughly tested and qualified with approved aerospace materials for commercial airborne applications. All of this means superior performance over the aircraft’s lifetime, fewer replacements, reduced system downtime, and lower total costs.

Vapor-sealed construction of GORE Mircowave/RF Assemblies, 7 Series

Applications

GORE Microwave/RF Assemblies, 7 Series is engineered to perform reliably in a variety of commercial airborne applications, including:

- L-Band Air-to-Ground (ATG) networks

- active electronically-steered phase arrays

- GPS connectivity

- Iridium

- Ku-Band SATCOM antennas

- SwiftBroadband

Benefits

GORE Microwave/RF Assemblies, 7 Series provides system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- durable vapor sealing prevents the ingress of water vapor and hash contaminants

- maintains low insertion/return loss with excellent phase stability up to 18 GHz

- less RF interference among electronic systems due to outstanding shielding effectiveness

- smaller diameters with greater flexibility and tighter bend radius for ease of installation

- longer system life for reduced downtime and less total costs

- increased design flexibility with robust, low-profile connector options

- proven performance with approved aerospace materials through qualification testing

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE Microwave/RF Assemblies, 7 Series.

| Electrical Property | Cable Type | ||

|---|---|---|---|

| 7E | 7L | 7M | |

| Maximum Frequency (GHz) | 18 | 7 | 2 |

| Maximum VSWR (dB through Max Frequency) Straight-to-Straight Connector Straight-to-Right Angle Connector | 1.25:1 1.30:1 | 1.25:1 1.30:1 | 1.25:1 1.30:1 |

| Maximum Insertion Loss (dB/m [dB/ft]) | 0.62 (0.19) | 0.33 (0.10) | 0.13 (0.04) |

| Standard Impendance (Ohms) | 50 ± 1 | 50 ± 1 | 50 ± 1 |

| Velocity of Propagation (Nominal) (%) | 85 | 85 | 85 |

| Time Delay (Nominal) ns/m [ns/ft]) | 3.94 (1.20) | 3.94 (1.20) | 3.94 (1.20) |

| Capacitance (pF/m [pF/ft]) | 85.3 (26.0) | 85.3 (26.0) | 85.3 (26.0) |

| Shielding Effectiveness (dB through Max Frequency) | > 90 | > 90 | > 90 |

| Dielectric Constant (Nominal) | 1.4 | 1.4 | 1.4 |

| Dielectric Withstanding Voltage (Vrms) Conductor-to-Conductor Conductor-to-Shield | 1500 1000 | 1500 1000 | 1500 1000 |

| Mechanical / Environemtnal Property | Cable Type | ||

|---|---|---|---|

| 7E | 7L | 7M | |

| Jacket Material | Engineered Fluoropolymer | ||

| Jacket Color | Purple | Black | Black |

| Center Conductor | Solid, SPC | Stranded, SPC | Solid, SPC |

| Dielectric Material | ePTFE | ||

| Nominal Outer Diameter (mm [in]) | 8.5 (0.34) | 12.3 (0.49) | 14.4 (0.57) |

| Nominal Weight (g/m [lbs/1000 ft]) | 150.9 (101.4) | 262.0 (176.1) | 328.0 (220.4) |

| Minimum Bend Radius (mm [in]) | 50.0 (2.0) | 62.5 (2.5) | 80.0 (3.15) |

| Crush Resistance (kgf/cm [lb/in]) | 8.95 (50.0) | 8.95 (50.0) | 8.95 (50.0) |

| Temperature Range (°C)a | -58 to +200 | -58 to +200 | -58 to +200 |

aContact Gore for applications with an operating temperature > 175°C.