Gore (日本ゴア)

GORE Abrasion Resistant Cable Jacket for Defense Land Systems

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Abrasion Resistant Cable

Overview of Abrasion Resistant Cable

Military standards now require high-speed copper cables connected to vectronics to meet new, more stringent durability requirements. But, adding more durability often includes thicker, heaver cable materials that can weigh vehicles down. Plus, bulky cables can be stiff, inflexible and hard to route in narrow pathways, especially in seats.

Gore offers a true, one-of-a-kind jacket for packaging high data rate cables that meets both new and existing standards without sacrificing size, weight or signal transmission performance.

GORE Abrasion Resistant Cable Jacket features a revolutionary fluoropolymer that meets EN3475-503 requirements. With our durable jacket, you no longer have to use additional protective sleeving now required for copper wires installed in vehicle seats.

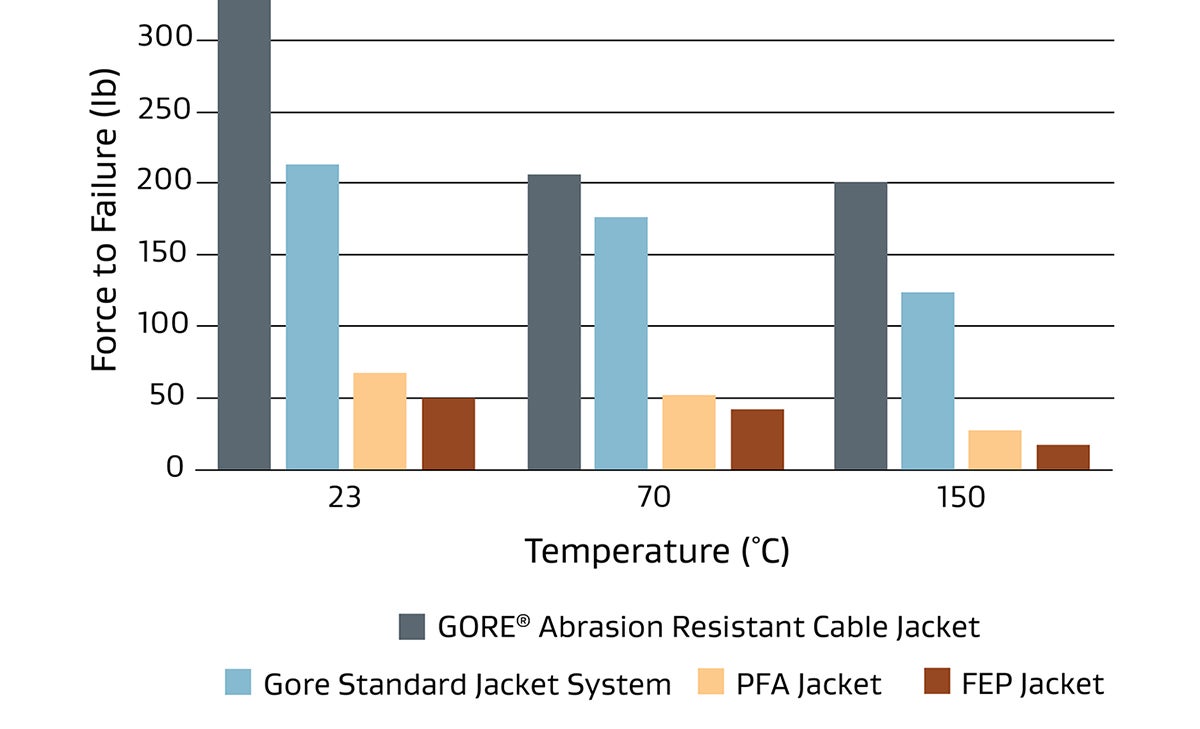

Using SAE AS4373™, Method 703, we compared our 100-ohm quadrax cables wrapped with our abrasion-resistant jacket against alternatives. As we expected, the results were undeniable! Our rugged cable jacket drastically outperformed PFA and FEP materials for superior cut-through resistance at high temperatures without cracking, splitting or breaking.

Cut-Through Resistance at High Temperatures

THINNER, LIGHTER & MORE FLEXIBLE

Another bonus is that our state-of-the-art materials technology is thinner, lighter weight and more flexible with tighter bendability than commonly used materials. Maintainers will find that routing copper wires and cables packaged with our jacket improves installation in tight configurations.

Features & Benefits

Outperforming common industry materials, GORE Abrasion Resistant Cable Jacket offers added features for packaging copper wires, including:

- revolutionary fluoropolymer fiber material

- abrasion- and cut-through resistant material

- chemically inert material

- highly flexible, thinner, lighter design

Our pioneering cable Jacket provides more benefits to system architects and engineers for best-in-class protection against typical land and vehicle conditions, like:

- meets strict EN3475 and SAE AS4373™ durability requirements

- superior resistance against high temps, abrasion, cut-through and more

- eliminates protective sleeving required for copper cables

- reliably transmits high-speed data and video

- contributes to valuable vehicle weight savings

- easier, faster routing because of more flexibility and tighter bending

- ideal for packaging GORE® High Speed Data Cables or industry alternatives

Technical Specs

These values demonstrate the electrical, mechanical and environmental performance of GORE® HDMI Cables, 2.0 version packaged with GORE Abrasion Resistant Cable Jacket for defense land systems. Download our data sheet for more cable characteristics, qualifications and part number.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed Gb/s | Up to 18 |

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 230.0 (70.0) |

| Maximum Skew Within Pair ps/m (ps/ft.) | 15.0 (4.6) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer Fiber Braid |

| Jacket Color | Black |

| Conductor | Silver-Plated Copper or SPC Alloy |

| Conductor Color Coding | High-Speed Pairs: Blue/White, Brown/White, Green/White, Red/White Singles: Orange, Violet, White, Yellow Triad: Gray, Pink, Tan |

| Dielectric Material | Expanded PTFE/PTFE |

| Cut-Through Resistance kg (lb) (SAE AS4373™-703) 23°C 70°C 150°C | 122 (270) 73 (160) 59 (130) |

| Scrape Abrasion Resistance Cycles (EN3475-503) 30°C & 55°C / F = 1.2 daN | > 8,000 |

| Temperature Range °C | -65 to +200 |