Gore (日本ゴア)

GORE Acoustic Vents for Industrial Applications

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Acoustic Vents

Overview of Acoustic Vents

Many outdoor industrial applications, from security cameras to intercoms to interactive displays, incorporate small, acoustically responsive MEMS microphones that rely on a housing port to receive acoustic signals. This makes outdoor industrial microphones highly vulnerable to damage or acoustic degradation from environmental contaminants such as water, dust, dirt or the extremely small particles that can be suspended in smoke or smog.

In outdoor industrial environments, GORE® Acoustic Vents for Industrial Applications can enhance the service life and acoustic integrity of MEMS microphones. That’s because our vents:

- Rapidly equalize pressure to increase service life, effectively manage condensation and reduce housing design complexity, weight and costs.

- Reliably protect sensitive electronics from moisture-related degradation.

- Effectively block ingress of contaminants: water, other liquids, dirt, dust or salts.

HOW CAN A MEMS MICROPHONE BE USED IN HARSH ENVIRONMENTS?

When the question is “How to protect MEMS microphones?” it’s important to define the hazard level. Some industrial environments require what is effectively a vent filter: that is, an acoustic membrane for microphone dust-and-splash protection. Other applications may require a fully watertight and fully dust-tight microphone protection for industrial settings. The same hazard levels (dust-and-splash and watertight) can also apply to outdoor speakers in harsh environments.

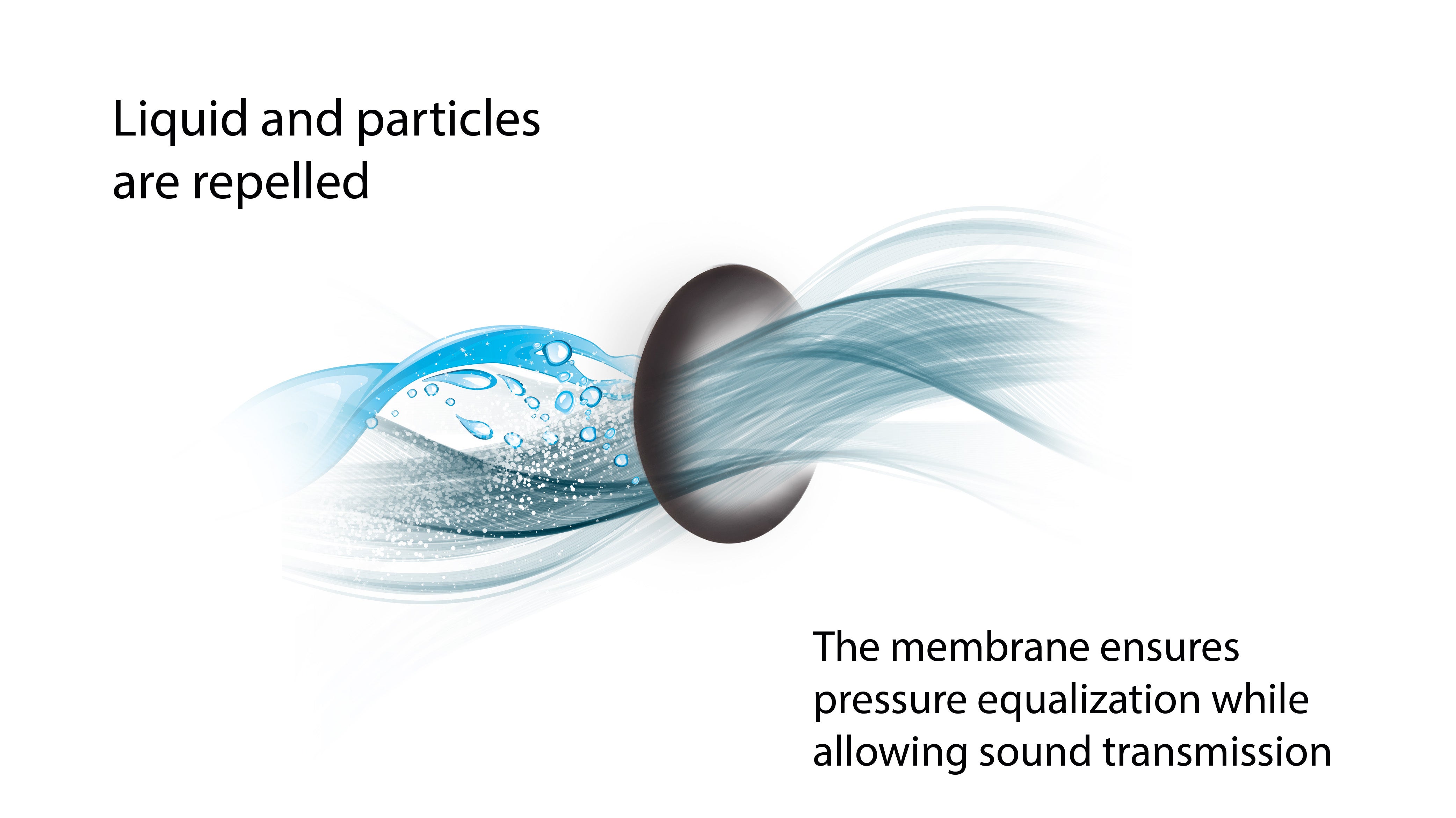

The portfolio of GORE Acoustic Vents for industrial applications offers solutions for all these requirements. Each of our vents features an innovative membrane, engineered to reliably protect against a specific level of contaminant ingress while enhancing acoustic performance and transparency.

The membrane repels liquids and particles while allowing pressure equalization and enabling clear sound transmission, so microphones in industrial applications can continue to perform reliably.

HOW CAN A MEMBRANE PASS SOUND, YET BLOCK WATER?

The membrane of our 400 Series is made of expanded polytetrafluoroethylene (ePTFE). Gore invented this highly versatile polymer, and we can tailor our membranes’ structure and performance characteristics to meet a wide range of application needs — up to and including waterproof acoustic membrane protection for outdoor industrial environments.

Whether your application requires exceptional barrier protection, or exceptional sound transmission, or a specific balance of both, the membrane makes it possible.

Applications for Industrial Acoustic Vents

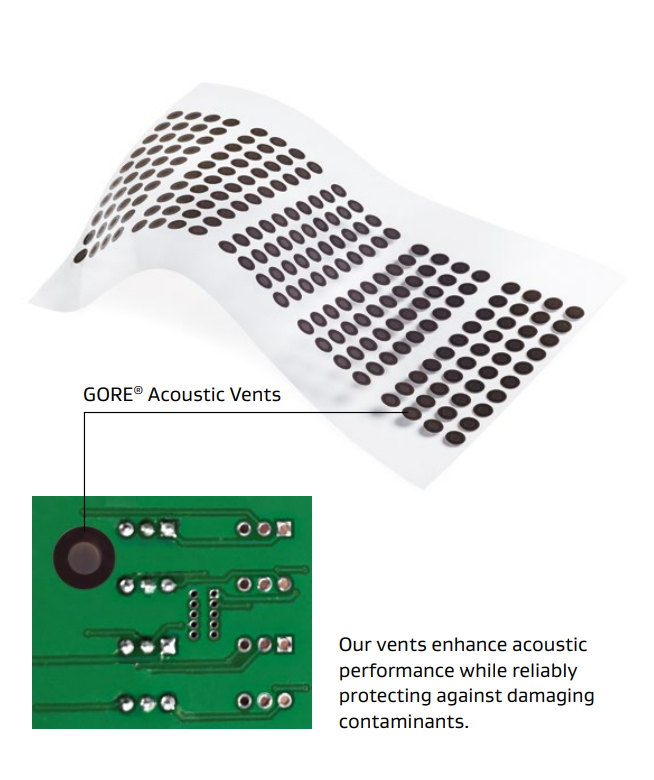

GORE Acoustic Vents for industrial applications enhance acoustic quality and protect against damaging contaminants.

When you need outdoor electronics vents that deliver reliable protection and exceptional sound transmission, choose GORE Acoustic Vents for industrial applications. Gore has the right solution to your environmental challenges, whether you a seeking a waterproof and dust-proof membrane for outdoor speaker protection, or industrial security camera microphone protection from dust and splashes.

TYPICAL INDUSTRIAL APPLICATIONS

Want to talk about your next project that requires industrial acoustic speaker protection, or acoustic vents for outdoor intercoms, acoustic vents for security cameras or acoustic vents for interactive displays in industrial environments?

Vent Selection Guidelines

Our portfolio of GORE Acoustic Vents for industrial applications includes two Series, each engineered to address a different set of vent performance requirements. Within each Series, you’ll find venting products designed to provide reliable acoustic performance and ingress protection for industrial microphones, and for industrial speakers/receivers.

SERIES 400: SUPERIOR FLUIDS AND DUST PROTECTION, OUTSTANDING ACOUSTICS

Series 400 eliminates the typical trade-offs between reliable waterproofing and superior sound quality. It combines our most advanced ingress protection with outstanding acoustic performance.

- Reliably waterproof: Delivers IPx8 protection (no water intrusion after immersion at 2 meters for 30 minutes).

- Durably oleophobic: Effectively repels oils, common industrial fluids and cleaning solutions that can threaten ordinary vent materials.

- Effectively dust-proof: Qualified IP6x dust-proof, and when tested in assembled devices, Gore’s Series 400 protects against airborne/smog-borne particulates as small as 1–10 μm in size.

SERIES 200: SPLASH AND DUST PROTECTION WITHOUT COMPROMISING SOUND

Series 200 effectively protects industrial devices from environmental splash and dust hazards while providing enhanced broadband acoustic transparency.

- Very good acoustics: Three-dimensional non-woven membrane maintains sound-wave integrity and protects against acoustic degradation, for enhanced microphone performance.

- Reliable splash resistance: Our oleophobic membrane provides a higher level of spray protection than ordinary woven mesh vents at a given level of acoustic performance.

- Efficient particle capture: Our three-dimensional membrane structure traps small particles of varied sizes and shapes much more efficiently than ordinary woven mesh vents, to enable better device reliability.

Standard Parts

FOR MICROPHONES IN INDUSTRIAL APPLICATIONS

The same apertures that enable microphone sound transmission also can make it easy for liquids and particles to enter and degrade both acoustic quality and device reliability. Gore offers a range of industrial acoustic vents designed to protect against these threats:

| For Splash & Dust Protection | For Superior Fluids & Dust Protection | |||||

|---|---|---|---|---|---|---|

| Series 234 | Series 434 | |||||

| P/N | ID [mm] | OD [mm] | P/N | ID [mm] | OD [mm | |

| AVP2341.53.5 | 1.5 | 3.5 | AVP4341.53.5 | 1.5 | 3.5 | |

| AVP2342.04.0 | 2.0 | 4.0 | AVP4342.04.0 | 2.0 | 4.0 | |

| AVP2342.55.0 | 2.5 | 5.0 | AVP4342.55.0 | 2.5 | 5.0 | |

| AVP2343.06.0 | 3.0 | 6.0 | AVP4343.06.0 | 3.0 | 6.0 | |

| Packaging: Supplied on sheets | Packaging: Supplied on sheets | |||||

See the technical specifications:

FOR SPEAKERS & RECEIVERS IN INDUSTRIAL APPLICATIONS

With their larger apertures, speakers and receivers can be more vulnerable to ingress of fluids and contaminants. The device’s magnets may also attract metal particles that can accumulate and degrade sound quality. Gore offers a range of industrial acoustic vents designed to protect against these threats:

| For Splash & Dust Protection | For Superior Fluids & Dust Protection | |||||||

|---|---|---|---|---|---|---|---|---|

| Series 212 | Series 412 | |||||||

| P/N | ID [mm] | OD [mm] | Parts across carrier | P/N | ID [mm] | OD [mm | Parts across carrier | |

| AVP2120713 | 6.5 | 13.0 | 8 | AVP4120713 | 6.5 | 13.0 | 8 | |

| AVP2120919 | 9.0 | 19.0 | 6 | AVP4120919 | 9.0 | 19.0 | 6 | |

| AVP2121325 | 13.0 | 25.0 | 4 | AVP4121325 | 13.0 | 25.0 | 4 | |

| AVP2122029 | 20.0 | 29.0 | 4 | AVP4122029 | 20.0 | 29.0 | 4 | |

| Packaging: Supplied on rolls | Packaging: Supplied on rolls | |||||||

Related Products

-

GORE Pair Thermal Insulation With Graphite for Better Heat Spreading

-

GORE Abrasion Resistant Cable Jacket for Civil Aircraft

-

GORE Leaky Feeder Antennas for Civil Aircraft

-

GORE Universal Pipe Gasket (Style 800)

-

GORE Space Cables for SpaceWire Applications

-

GORE Type SPM Space Cables For LEO Applications