Gore (日本ゴア)

GORE Aerogel Insulation for Better Thermal Protection

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: Aerogel Insulation

Overview of Aerogel Insulation

Aerogels are a class of materials with a unique morphology. Aerogels are highly porous, typically comprised of 95-99% air by volume. These low-density, highly-porous solid materials are light and durable. These characteristics make aerogel insulation an effective solution for many different applications.

Silica aerogel, in particular, has unique insulative properties. Aerogel thermal conductivity is lower than that of air, so it’s capable of providing a greater thermal resistance benefit than air. This is due to having pore sizes in the mesoporous range of 2–50 nm. These restricted pore diameters are smaller than the mean free path of air, forcing molecules to take a tortuous path through the material, inhibiting transfer of heat. This is known as the Knudsen effect.

Aerogel Insulations

Aerogel insulation has been used in the aerospace industry for many years, often in the form of thick blankets of aerogel suspended in a thick fabric structure. Recently, companies started to look at using silica aerogel in electronics.

Most aerogel insulations take the form of a silica aerogel coated into or onto a substrate, such as a non-woven. This typically leads to an uneven distribution of aerogel throughout the structure, which can cause:

- Variation in the aerogel insulation thermal conductivity

- Shedding of aerogel particles, as the aerogel is not bound to the structure

However, Gore recently developed and launched GORE Thermal Insulation, an aerogel-based product that solves those issues of consistency, and shedding.

- Our silica aerogel insulation’s thermal conductivity is about 20% lower than that of air, due to our highly consistent distribution of aerogel within a PTFE matrix.

- GORE Thermal Insulation is also superior to other insulations because the aerogel is bound by the PTFE matrix, which eliminates particulation.

- Our processing enables us to target specific insulation thicknesses, and maintain low thermal conductivity across our portfolio of offerings. These are distinct advantages for aerogel in electronics, where gap sizes vary from device to device.

Designing and Installing Aerogel Insulations

Selecting the appropriate design for the insulation (thickness and area) is critical to achieving optimal performance results. When designing an aerogel thermal solution, it is important to optimize the area of the insulation relative to the area of the surface hot spot.

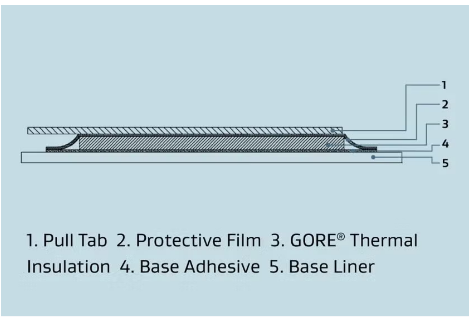

GORE® Thermal Insulation cross section

GORE Thermal Insulation is provided in finished good form, meaning the insulation is die-cut to the appropriate size and shape. Installing an aerogel insulation into an electronic device requires the use of adhesives and cover films. Gore provides guidance and support to customers to ensure successful aerogel insulation installations.

Aerogel Insulation Properties

GORE Thermal Insulation has a thermal conductivity of about 0.020 W/m•K, depending upon its thickness. The specific heat capacity of our aerogel insulation finished good is 1.8J/g °C. In use, the max temp of aerogel insulation is dependent upon the adhesives used. For GORE Thermal Insulation finished goods, the max use temp is typically 100 °C. By selecting adhesives suitable for high temperatures, the aerogel insulation can be used up to ~320 °C.

| Characteristic | ||||||

|---|---|---|---|---|---|---|

| Insulation thickness availablea | 0.10 mm | 0.12 mm | 0.23 mm | 0.28 mm | 0.38 mm | 0.53 mm |

| Adhesive encapsulation width (minimum)b | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1.5 mm |

| Thermal conductivity (k)c | 0.021 W/m•K | 0.020 W/m•K | ||||

| Compression @ 100 kPa (14.5 psi) | 13% | 8% | ||||

| Specific heat capacityd | 1.8 J/g °C | |||||

| Bulk density | 0.37 g/cc | |||||

| Operating temperaturee | -40°C to 100 °C | |||||

| Protective cover film | Black PET | |||||

| Adhesive type | Acrylic | |||||

| RoHSf | Meets threshold requirements | |||||

| Max part size | 100 mm x 200 mm | |||||

a Nominal thickness based on reported values of thickness of each component of the stack-up.

b Nominal minimum width.

c Nominal conductivity value based on a modified version of ASTM C518.

d Nominal heat capacity measured according to ASTM E2716 Method B at 75 °C.

e Alternate adhesives required to exceed 100 °C.

f To the best of our knowledge, the product listed above does not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU and meets the substance restrictions of Article 4 of RoHS Recast including Commission Delegated Directive 2015/863.

*All values are based on nominal characteristics and do not represent the specification and tolerance.

Related Products

-

GORE CAN Bus Cables for Defense Aircraft

-

GORE Dioxin and Furan Catalytic Filter Bags

-

GORE FireWire Cables for Defense Aircraft

-

GORE Microfiltration Media for Non-Implantable Medical Devices and In Vitro Diagnostics

-

GORE Pair Thermal Insulation With Graphite for Better Heat Spreading

-

GORE-SELECT Membranes (PEM) for Fuel Cells