Gore (日本ゴア)

GORE Ambient Air Filters for Outdoor Cabinets

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Ambient Air Filters

Overview of Ambient Air Filters

GORE® Cooling Filters (GCF) enable you to lower your system costs by taking full advantage of the natural thermal efficiencies of ambient air. Our filters protect your equipment from harmful contaminants and corrosives for several years while requiring no regular maintenance.

High reliable cooling technology

Unlike large, energy consuming cooling systems, GORE® Cooling Filters enable you to take full advantage of the natural thermal efficiencies of ambient air while simultaneously lowering your system costs. GORE® Direct Air Cooling Filters are smaller and require fewer parts than bulky HEX and AC units. This reduces space usage and simplifies maintenance.

ABOUT DIRECT AIR COOLING (DAC) TECHNOLOGY WITH GORE® COOLING FILTERS

GORE® Cooling Filters offers the most efficient and reliable cooling technology available for outdoor electronic enclosures. Unlike closed loop systems like AC and HEX, GORE® Cooling Filters enable the use of DAC by providing critical environmental protection – allowing you to take full advantage of natural thermal efficiency of air.

INCREASE SYSTEM RELIABILITY WITH GORE® COOLING FILTERS

Gore‘s standard product line of Cooling Filters offers unique sizes that incorporate the high performance Gore filtration media into a lightweight, durable ABS polymer frame. The product offering can be integrated into a variety of enclosure designs in order to reduce weight and cost.

BENEFIT FROM OUR APPLICATION EXPERTISE AND EXPERIENCE

With sales and market experience of more than 15 years and several hundred thousand GORE® Cooling Filters deployed globally, Gore has gathered unparalleled in-depth application knowledge. Based on global field testing under various climatic conditions, we are in the position to provide our customers with realistic lifetime modeling projections that help to minimize maintenance uncertainties.

Features & Benefits

DIRECT AIR COOLING REDUCES THE HIGH CAPITAL AND OPERATING COST OF HEAT EXCHANGERS AND AIR CONDITIONING

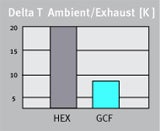

Improves Thermal Efficiency

- No thermal transfer loss

- Better Watts/K cooling capacity

- More uniform airflow through cabinet

- Wider temperature deployment range

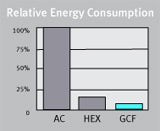

Lower Operational Costs

- Uses less energy than AC and HEX

- Requires less maintenance

- Significantly improves MTBF

Lower Capital Expenses

- Cost much less than air conditioning

- Lower power consumption reduces the back-up energy requirement

- Simplifies component placement

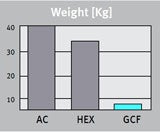

Smaller Size and Less Noise

- Smaller installation area for a given cooling capacity

- Lower weight reduces transportation and installation costs

- No external fans for lower noise emissions

Direct air is one of the most efficient cooling methods available. When combined with high efficiency filters, DAC offers high protection from salt, dust, water and other contaminants. This results in the most reliable and cost-effective protection for your sensitive electronics. GORE® Cooling Filters technology enables direct air cooling by providing critical contamination protection while still allowing high airflow. Unlike bulky heat exchangers or costly air conditioning systems, GORE® Cooling Filters let you benefit from the thermal efficiency of ambient air while reducing capital and operational costs.

GORE® COOLING FILTERS INCREASE RELIABILITY AND LOWER COSTS

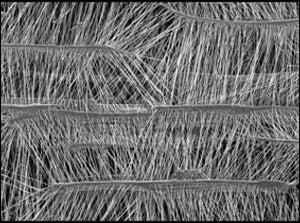

High efficiency membrane protects from even submicron particles. Our unique expanded polytetrafluoroethylene membrane’s microporous structure provides E12 particle filtration efficiency according to EN188 yet still allows high flows of cool, clean air to pass through to system electronics. It provides long term protection and easily meets an IP6X dust rating.

Protects against Salts and Corrosive Particles. GORE® Cooling Filter’s inert membrane easily screens out damaging salt sprays, and other corrosives. This ensures longer life for system electronics and cabinetry.

Water Tight Construction. The filter’s hydrophobic membrane, ABS polymer frame, and robust sealing system prevent water ingress in alignment with an IPX5 ingress protection rating.

High Durability, Lower Opex Costs. Besides their low initial costs and small size, GORE® Cooling Filter’s ruggedized construction and fewer replacement parts also leads to significant reductions in ongoing maintenance and service costs. No matter which GORE® Cooling Filter you choose for your electronic enclosure, our applications team will ensure the most operationally efficient cooling solution.

WHY USE GORE MEMBRANE COOLING FILTERS VERSUS NON-MEMBRANE FILTERS?

Reliable protection of system electronics requires highly efficient filtering of ambient air to remove submicron particles and aerosols while also preventing water ingress into the cabinet. This is best achieved by using membrane filter media, which provides 99.5% particle filtration efficiency at the 0.1um level yet still allows high airflow. Not only do membrane filters eliminate costly failures caused by corrosion and other pollutants, but they are also maintenance free and have longer lifetimes than non-membrane alternatives.

Unlike conventional non-membrane filters, GORE® Cooling Filters have been specifically developed for outdoor cooling and protection under extreme environmental and climatic conditions. GORE® Membrane offers the lowest pressure drop at a given filtration efficiency, allowing you to select smaller fans and limit noise pollution.

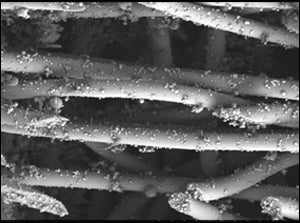

Membrane Filter (500X SEM)

GORE expanded PTFE membrane’s microporous structure provides higher filtration efficiency

Non-Membrane Filter (500X SEM)

The open structure of non-membrane filters lets dust and small particles pass right through into cabinet

Engineering & Support

FAN CONTROL

Typical initial resistance of a GORE® Cooling Filter is approximately 50 Pascals and increases over its lifetime depending on the air particle concentration and operating conditions. To maximize filter lifetime, selecting the right fan is critical.

The fans should be set to ensure minimum temperature fluctuation within specified ranges. Control of the internal temperature is influenced by many variables including: ambient temperature, solar radiation, heat load and filter resistance. These variables are addressed by using fan control logic that offers either simple speed control or advanced (thermostatic) features depending on system requirements.

Gore Applications Engineers can help you to select the appropriate fan type and position to optimize the life of your electronics and filter.

FILTER SEALING

To ensure a good seal between enclosure and GORE® Cooling Filter, there is a compressible gasket integrated in the frame.

DESIGN AND MOUNTING CONSIDERATIONS

The pleats must be oriented vertically to ensure optimal performance. The filter is designed for unilateral flow, refer to the airflow arrow on the label. Integrating the GORE® Cooling filter in the enclosure design is typically done using mounting brackets or frames as illustrated in the following graphic.

It is critical to maintain a consistent gasket compression around the perimeter. Additionally, a minimum of 10 mm clearance on each filter side is recommended to prevent distortion from thermal expansion. For further design and mounting recommendations specific to your application, please contact a Gore specialist.

Performance Characteristics

Selecting appropriate GORE® Cooling Filter size requires a basic understanding of the required airflow or heat dissipation as well as the available mounting area for the filter.

All installations have variations in the environmental specifications. The Filter Performance table is used to show relative performance at standard parameters. Specific calculations are required for individual installations and may differ from standard parameters.

Gore application engineers are available to help solve your heat dissipation needs, calculating the filter performance for your specific application and recommend an available filter size.

Typical Performance Characteristics per Filter Size

| Part Number | Filter Attributes | Filter Performance | |||||

|---|---|---|---|---|---|---|---|

| Height (mm) | Width (mm) | Depth (mm) | Weight (kg) | Maximum Air Flow (m3/hr) | Equivalent Heat Dissipation Capacity (W) 1 | New Filter Pressure Drop (ΔP) vs. Airflow (Q) Curves | |

| CF541163 | 692 | 500 | 48 | 2.7 | 500 | 1613 | ΔP (Pa) = 0.11 x Q (m³/h) |

| CF541211 | 200 | 345 | 90 | 1.2 | 162.5 | 524 | ΔP (Pa) = 0.34 x Q (m³/h) |

| CF541237 | 605 | 454.5 | 57.2 | 2.2 | 450 | 1452 | ΔP (Pa) = 0.12 x Q (m³/h) |

| CF541238 | 455 | 305 | 57.2 | 1.2 | 200 | 645 | ΔP (Pa) = 0.28 x Q (m³/h) |

| CF541239 | 305 | 230 | 57.2 | 0.7 | 100 | 323 | ΔP (Pa) = 0.56 x Q (m³/h) |

| CF541242 | 605 | 455 | 80 | 3.3 | 625 | 2016 | ΔP (Pa) = 0.09 x Q (m³/h) |

| CF541252 | 305 | 455 | 57.2 | 1.2 | 212.5 | 685 | ΔP (Pa) = 0.26 x Q (m³/h) |

| CF541257 | 494 | 440 | 57.4 | 1.9 | 337.5 | 1089 | ΔP (Pa) = 0.17 x Q (m³/h) |

| CF541258 | 850 | 440 | 57.2 | 3.0 | 625 | 2016 | ΔP (Pa) = 0.09 x Q (m³/h) |

| CF551278 | 205 | 440 | 80 | 1.2 | 187.5 | 605 | ΔP (Pa) = 0.30 x Q (m³/h) |

| CF551279 | 440 | 440 | 80 | 2.4 | 450 | 1492 | ΔP (Pa) = 0.12 x Q (m³/h) |

1 Assuming ΔT of 10 °C