Gore (日本ゴア)

GORE CAN Bus Cables for Defense Land Systems

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: CAN Bus Cables

Overview of CAN Bus Cables

HIGH-QUALITY SIGNALS

Seconds matter during any military operation, so soldiers must receive vital Intel in time or risk jeopardizing the mission and their safety. With cables being a key component in systems, they have to transmit data as fast as possible on vectronics digital networks no matter the circumstances.

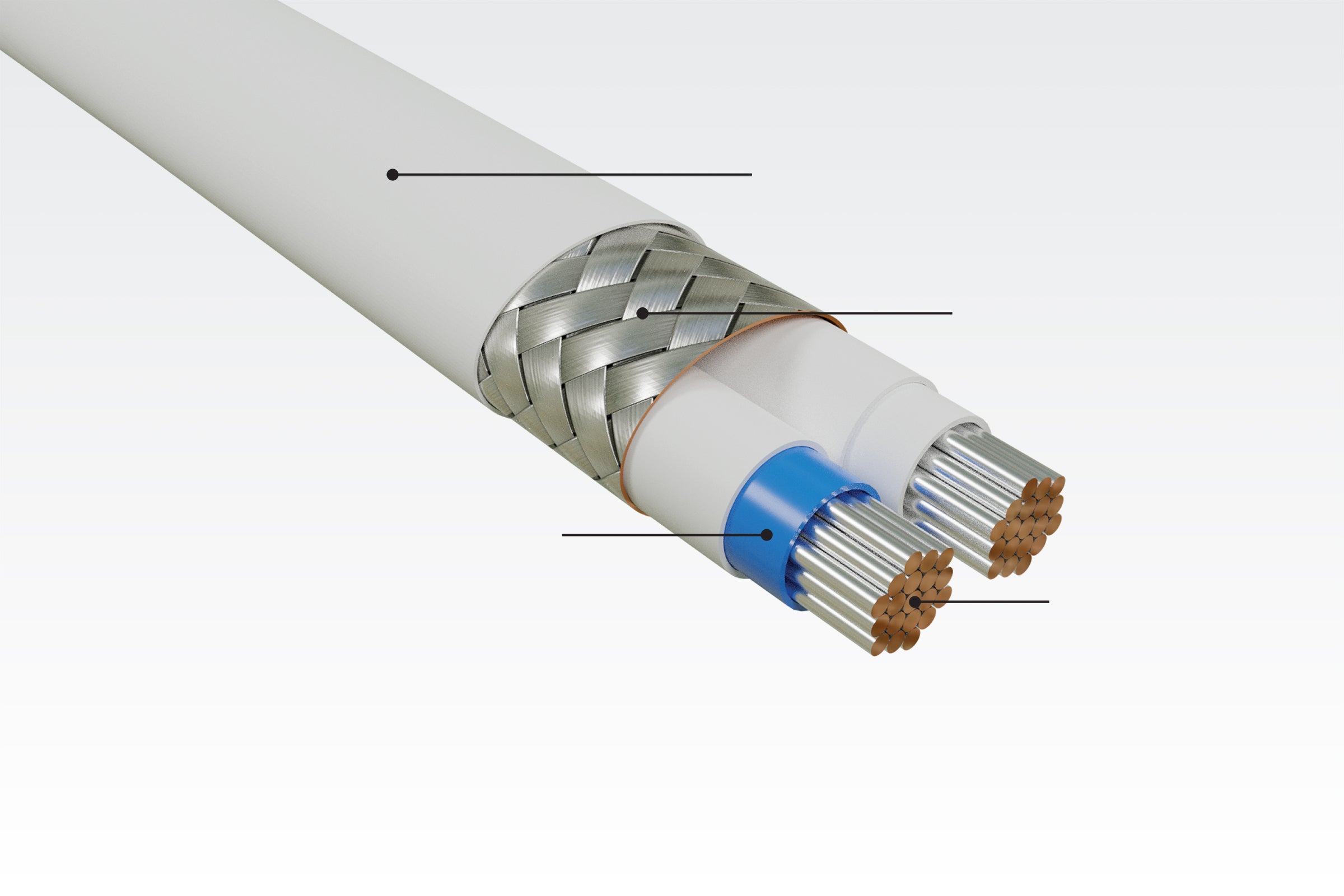

Built for speed and accuracy, GORE CAN Bus Cables reliably send high-quality signals for secure data transmission up to 1 GHz. They maintain controlled impedance at 120 ohms in whatever conditions they encounter in the field. The reason is their unique multi-layer construction that provides versatile protection to shield wires from extreme impact. Our cables can endure low-to-high temperatures, severe weather, repeated vibration, harsh contaminants and more.

FAST, TROUBLE-FREE ROUTING

A smaller design is essential for routing and installation where space is limited. Our CAN Bus cables are 40% smaller than alternative designs, which makes them fundamentally lighter. A smaller diameter also means improved flexibility and reduced bend radius for quick routing and installation without any trouble. Maintainers will also like that our cables have a unique inverted dielectric that makes wire prep and insertion in smaller connector systems much easier.

When put to the test, GORE CAN Bus cables for defense land systems maintain stable communications on vectronics digital networks over the vehicle lifetime. Ultimately, troops gain a decisive edge in volatile situations because they can rely on electronic systems with cables that won’t fail.

Compact footprint of GORE CAN Bus Cables.

Applications

GORE CAN Bus Cables are suitable for today’s faster vectronics digital networks and other applications requiring secure, accurate high-speed data transfer, like:

- controller area networks

- data links

- electronic diagnostics

- HD streaming video systems

- mission systems

- serial buses

- vectronics digital networks

Our cables can also be terminated with a variety of leading high-speed connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 and 22D contacts.

Features & Benefits

GORE CAN Bus Cables are engineered with unique features that make them more durable against challenging environmental factors and in-vehicle conditions, including:

- inverted dielectric design with smaller diameters

- temperature- and abrasion-resistant materials

- chemically inert materials

These cables provide system architects and engineers with many benefits that improve their overall performance in defense vehicles, like:

- high-quality signals for fast, secure data transmission up to 1 GHz

- proven controlled impedance at 120 ohms

- versatile protection against extreme mechanical/environmental impact

- size and weight savings with 40% smaller diameters than alternative designs

- trouble-free routing with improved flexibility and reduced bend radius

- easier wire prep and insertion in smaller connector systems

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawings

These values demonstrate the electrical, mechanical and environmental performance of GORE CAN Bus Cables for defense land systems. Download our data sheet for more cable characteristics, qualifications and part numbers. Also, fill out a short form for instant access to drawings.

| Elec./Mech./Environ. Properties | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1 |

| Standard Impedance Ohms | 120 ± 10 |

| Typical Operating Voltage V | <15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft) | 42.0 (12.8) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper or SPC Alloy |

| Conductor Color-Coding | Blue/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

Related Products

-

GORE Trackless High Flex Cables for Semiconductor Production Equipment

-

GORE High Temperature Capacitors for Oil And Gas Power Electronics

-

GORE Adhesive Series Protective Vents For Venting Solutions

-

GORE Filter Bags for the Metals Industry

-

GORE Space Cables and Assemblies: Datalines

-

GORE Rastex Weaving Yarn for Filtration Applications