Gore (日本ゴア)

GORE Coaxial Cables for Defense Land Systems

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Coaxial Cables

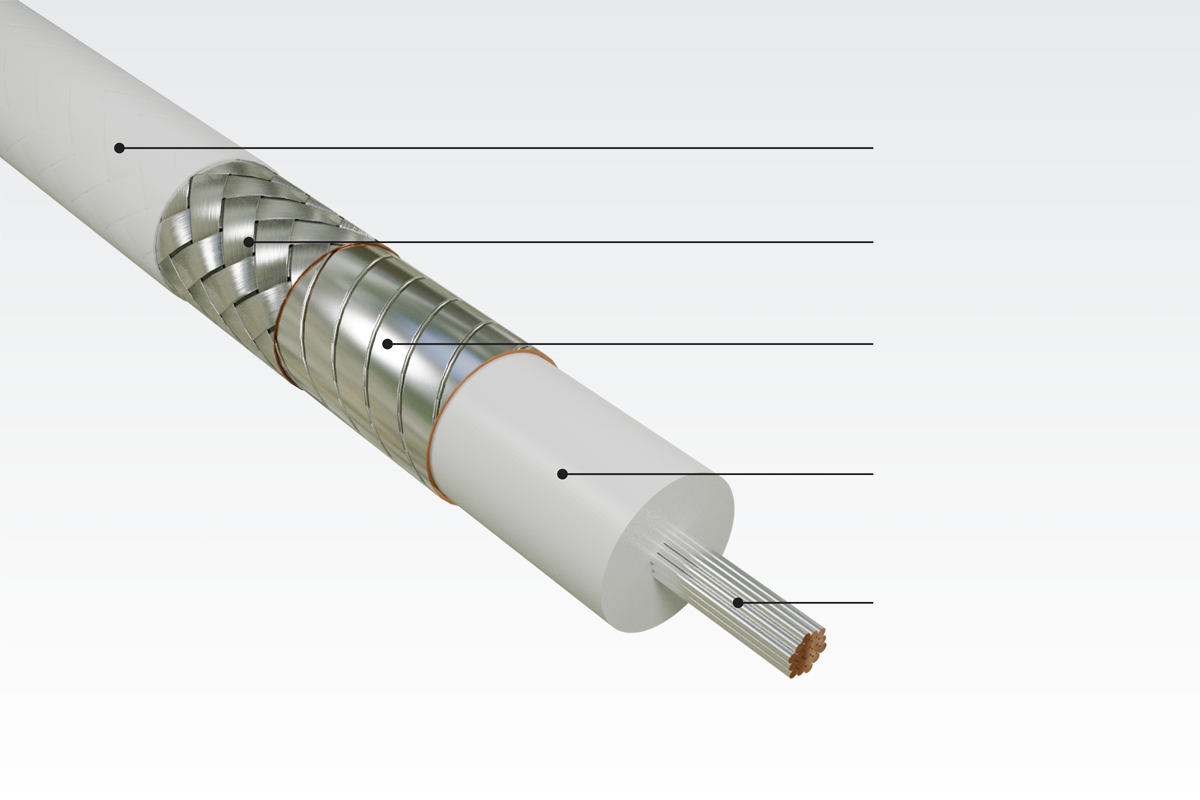

Overview of Coaxial Cables

Our defense customers have told us that they need a dependable coaxial cable operating at 75 ohms while streaming secure video in ultra-high definition. They also want cables to be smaller and lighter to save valuable weight while being more flexible and easier to install in vehicles.

We listened to our customers’ demands and offer GORE Coaxial Cables that operate reliably at 75 ohms with controlled impedance. They’re specifically designed for 4K video interface systems in many types of armored vehicles. Our cables optimize signals and video transmission with ultra-low loss up to 6 GHz in applications like remote-controlled turret cameras. With proven outstanding shielding effectiveness, they also reduce RF interference among vital systems.

ADDED DURABILITY WHILE SAVING WEIGHT

Our 75-ohm coaxial cables feature a specialized fluoropolymer jacket that improves durability for superior protection against difficult conditions that ground forces typically encounter during missions. For instance, heavy snow, arctic temperatures, torrential rain, high heat, humidity and desert regions. These rugged military high-speed data cables also tolerate repeated vibration, high abrasion, hazardous chemicals, harsh contaminants and more.

More durability usually means thicker materials that can take up valuable space in vehicles and make cables stiff to route. But, our cable insulation is thinner and lighter without compromising on durability. They’re also easier and faster to install in overcrowded vehicles because of their smaller diameter that increases flexibility with a tighter minimum bend radius. They also exceed stringent industry coaxial cable standards while also meeting SMPTE (Society of Motion Picture and Television Engineers) requirements.

Small, lightweight construction of GORE Coaxial Cables.

Applications

With proven performance that’s thoroughly tested and qualified before going to market, GORE Coaxial Cables provide trustworthy results in several applications, including:

- HD streaming camera/video systems

- Remote-controlled turret cameras

- Vectronics displays

Features & Benefits

We manufacture GORE Coaxial Cables with specialized features that make them more durable against challenging environmental factors and in-vehicle conditions, including:

- chemically inert materials

- EMI shielding materials

- abrasion- and temperature-resistant materials

- lighter weight design with smaller diameters

These military cables provide system architects and engineers a handful of benefits that ensure their reliability and extended life in combat vehicles, like:

- optimized 4K signals and video transmission with ultra-low loss up to 6 GHz

- proven to maintain controlled impedance at 75 ohms

- outstanding EMI shielding effectiveness for less RF interference among electronics

- superior protection against extreme temperatures, weather, abrasion, more

- significant weight savings with smaller, lighter weight construction

- easier routing with more flexibility and tighter bend radius

- exceed stringent military requirements and meet SMPTE standards

Technical Specs & Drawing

These values demonstrate the electrical, mechanical and environmental performance of GORE Coaxial Cables for defense land systems. Download our data sheet for more coaxial cable characteristics, qualifications and part numbers. Also, fill out a short form for instant access to a selected drawing.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 6 |

| Standard Impedance Ohms | 75 ± 2 |

| Typical Operating Voltage V | < 420 |

| Nominal Velocity of Propagation % | 83 |

| Nominal Time Delay ns/m (ns/ft.) | 4.0 (1.26) |

| Capacitance pF/m (pF/ft.) | 53.2 (16.2) |

| Shielding Effectiveness dB through 2 MHz | >100 |

| Nominal Dielectric Constant | 1.4 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Silver-Plated Copper |

| Dielectric Material | Expanded PTFE |

| Temperature Range °C | -55 to +200 |

Related Products

-

GORE NOx and NH3 Catalytic Filter Bags

-

GORE Type SPLD Space Cables For Geostationary Earth Orbit (GEO) Applications

-

GORE 1000 Series Gasket Tape

-

GORE High Temperature Capacitors for Oil And Gas Power Electronics

-

GORE Hook-Up Wires For Defense Land Systems

-

GORE Insulated Wires For Oil And Gas Downhole Equipment