Gore (日本ゴア)

GORE Cover For Organic Waste Treatment

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: Cover For Organic Waste

Overview of Cover For Organic Waste

Efficiency

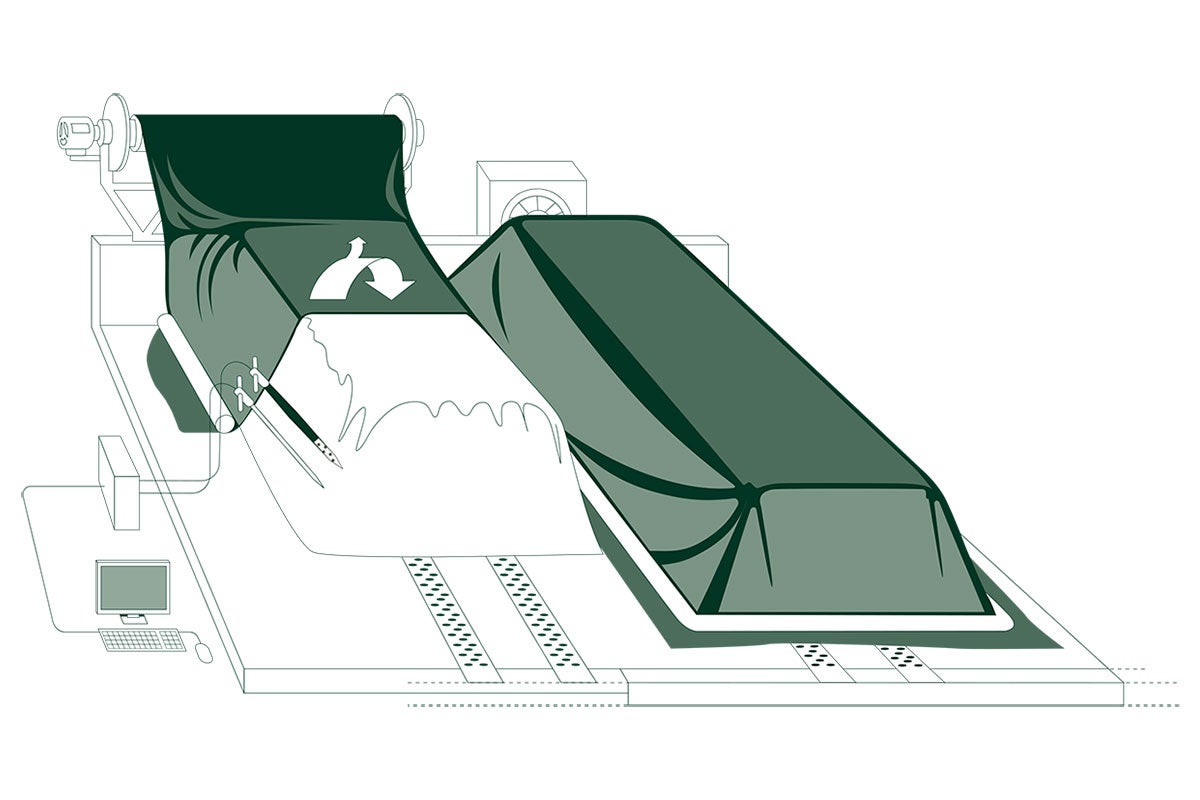

GORE Cover, the fully integrated composting solution for the treatment of organic waste. Recognized as the leader for in-vessel composting worldwide, GORE® Cover is cost efficient to install and operate while providing optimized process control for producing consistent high quality compost and effectively controlling odors and emissions.

Flexibility

GORE Cover is approved and proven in more that 150 composting plants in more than 20 countries. GORE Cover meets the strictest of regulatory requirements worldwide. Facilities using GORE Cover are fully comparable with established technologies – without the need for expensive buildings and bio-filtering installations.

Approved

The unique design flexibility of GORE Cover means that it is capable to process a variety of input materials be it green waste, food waste, source separated organics, biosolids or MSW and for input volumes from as little as 2,000 tons to greater than 200,000 tons per year.

About Waste Treatment

GORE Cover is all about waste treatment – and saving money

Whoever wants to survive in the long run has to:

- increase the efficiency of plant throughput performance

- create a return on investment by marketing the highest quality compost as end product

- reduce initial investment and running costs

- ensure that the plant adheres to all legal regulations by operating within threshold limits at all times

In this challenging business environment GORE Cover represents trendsetting technology for aerobic, organic waste treatment using special semi-permeable membranes. It offers plant operators an identical performance profile and the same environmental protection as halls, tunnels, boxes or containers – at substantially lower costs.

Globally, GORE Cover – as the market leader – is used in over 150 composting and organic waste treatment plants, with a total plant throughput amounting to more than 2 million tons per annum.

Today, fully enclosed waste treatment plants can be operated highly economically – with GORE Cover.

Complete System

GORE Cover is more than a cover – it’s a complete system

The system behind GORE Cover

GORE Cover stands for a comprehensive aerated system proven in multiple sites. It is equipped with an oxygen controlled, positively aerated system and an oxygen and temperature monitoring device. This creates ideal composting conditions within the heap while efficiently trapping odors and other emissions such as dust and VOCs. This results in a higher throughput on a smaller footprint of composting area – with little energy consumption and human involvement. Biological washing and filtration is not necessary.

System support by Gore

In addition to the supply of the laminate and the technical system Gore provides intensive training to ensure sustainable operation of the treatment process.

Thus GORE Cover combines a number of advantages in one product: higher throughput combined with cost effectiveness in terms of personnel, energy consumption and approved regulatory conformance.

Technical Applications

One solution for a wide spectrum of technical applications

GORE Cover allows professional plant operation under the following conditions:

- As a textile in-vessel system

- As a heap or as a box shaped solution

- In new plants or as a retrofit

- From deserts to extreme cold environments

- From manual handling to mechanised handling of covers with machinery

- From hundreds to many thousands of tons of annual throughput

Related Products

-

GORE Leaky Feeder Antennas for Civil Aircraft

-

GORE Filter Bags for the Waste-to-Energy Industry

-

GORE Magnet Wire for Oil & Gas Downhole Motors

-

GORE Laptop Heat Dissipation for Sustained Peak Performance

-

GORE Acoustic Vents for Industrial Applications

-

GORE Aerogel Insulation for Better Thermal Protection