Gore (日本ゴア)

GORE Delay Or Avoid System-on-Chip Throttling (SoC)

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: Avoid System-on-Chip Throttling

Overview of Avoid System-on-Chip Throttling

In mobile electronic devices, the System on a Chip (SoC) serves as a microcontroller, integrating multiple processors on a single chip. This compact system combines components for data or graphics processing, memory, secondary storage, and other essential circuits.

Due to its critical role in controlling numerous device functions, the SoC often becomes the primary heat generator. This heat can create surface hot spots on mobile devices. To maintain safe surface temperatures below ~45 °C, engineers must manage the SoC’s performance by reducing its power output to prevent overheating.

For this reason, thermal engineers working on smartphones, laptops, smartwatches, AR/VR devices, and other mobile electronics prioritize effective thermal management. The process begins with an in-depth analysis of SoC heat outputs.

Analyzing SoC Heat Outputs

Understanding the heat output of an SoC requires a thorough thermal analysis. Heat generation varies depending on how the chip is used. For example:

- Data processing tasks may produce different power requirements compared to

- Graphics-intensive operations, which generate higher heat levels.

Engineers often use IR cameras to capture a general heat signature and thermocouples for precise temperature measurements. These tools provide valuable data for creating strategies to manage heat effectively.

Dissipating SoC Heat Outputs

After completing the thermal analysis, engineers focus on methods to redirect heat from the SoC. This allows the chip to operate at higher power levels for extended periods without triggering performance throttling.

Common heat dissipation strategies include:

- Using Thermal Interface Materials (TIMs) and Thermal Pastes:

These materials connect the SoC to heat spreaders, such as graphite, heat pipes, or vapor chambers, which distribute heat across cooler areas of the device. - Employing GORE® Thermal Insulation:

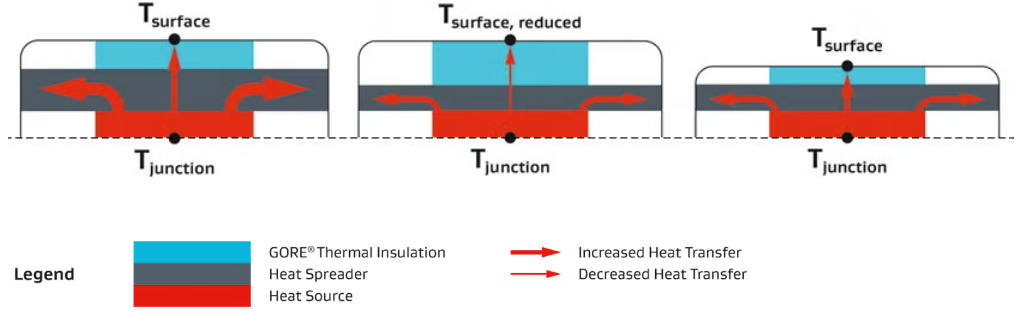

This innovative insulation prevents the heat generated by the SoC from creating hot spots on the device’s surface. By maintaining a lower surface temperature, GORE® Thermal Insulation helps delay or avoid performance throttling.

GORE Thermal Insulation can lower the surface temperature, and when used in combination with graphite, can allow for an increase the peak performance of the SoC, or increase the length of time spent at a specific power output level before throttling occurs.

IMPROVE THERMAL MANAGEMENT WITHOUT COMPROMISES

Combining GORE Thermal Insulation with graphite lets designers replace the large air gap with a thinner piece of insulation that leaves space to add more graphite. This combined solution can help to optimize performance for end-users, reduce surface hot spot temperatures, or enable development of thinner high-performance devices.

| Increase Performance with GORE Thermal Insulation | Reduce Hotspot Temperature with GORE Thermal Insulation | Thinner Product Design with GORE Thermal Insulation |

|---|---|---|

|

|

|

Related Products

-

GORE Microfiltration Media for Pharmaceutical, Bioprocessing, Food and Beverage Filtration

-

GORE Screw In Series Protective Vents for Solar Energy Systems

-

GORE Aerogel Insulation for Better Thermal Protection

-

GORE Round Cable For High Flex Applications (Custom Solutions)

-

GORE Microwave/RF Assemblies for Spaceflight Applications

-

GORE Rastex Weaving Yarn for Filtration Applications