Gore (日本ゴア)

GORE DVI Cables (Digital Only) for Defense Aircraft

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: DVI Cables

Overview of DVI Cables

Engineers have often told us that it’s challenging designing aircraft harnesses with digital components in DVI (digital video interface) systems that can reliably stand up to demanding radar environments.

Gore offers a single-link cable solution designed specifically for the digital component of DVI systems that the military can always trust and rely on during missions.

GORE DVI Cables (Digital Only) are proven to deliver exceptional signal quality and high data rate video transmission in demanding EMI (electromagnetic interference) environments. They also support the highest video resolution for optimal viewing on aircraft cockpit and workstation displays. Unlike many substitutes, they meet rigorous military aerospace standards for impedance control, insertion loss, skew and EMI shielding necessary for stable performance in DVI systems.

Easy Fit into Standard Harness Designs

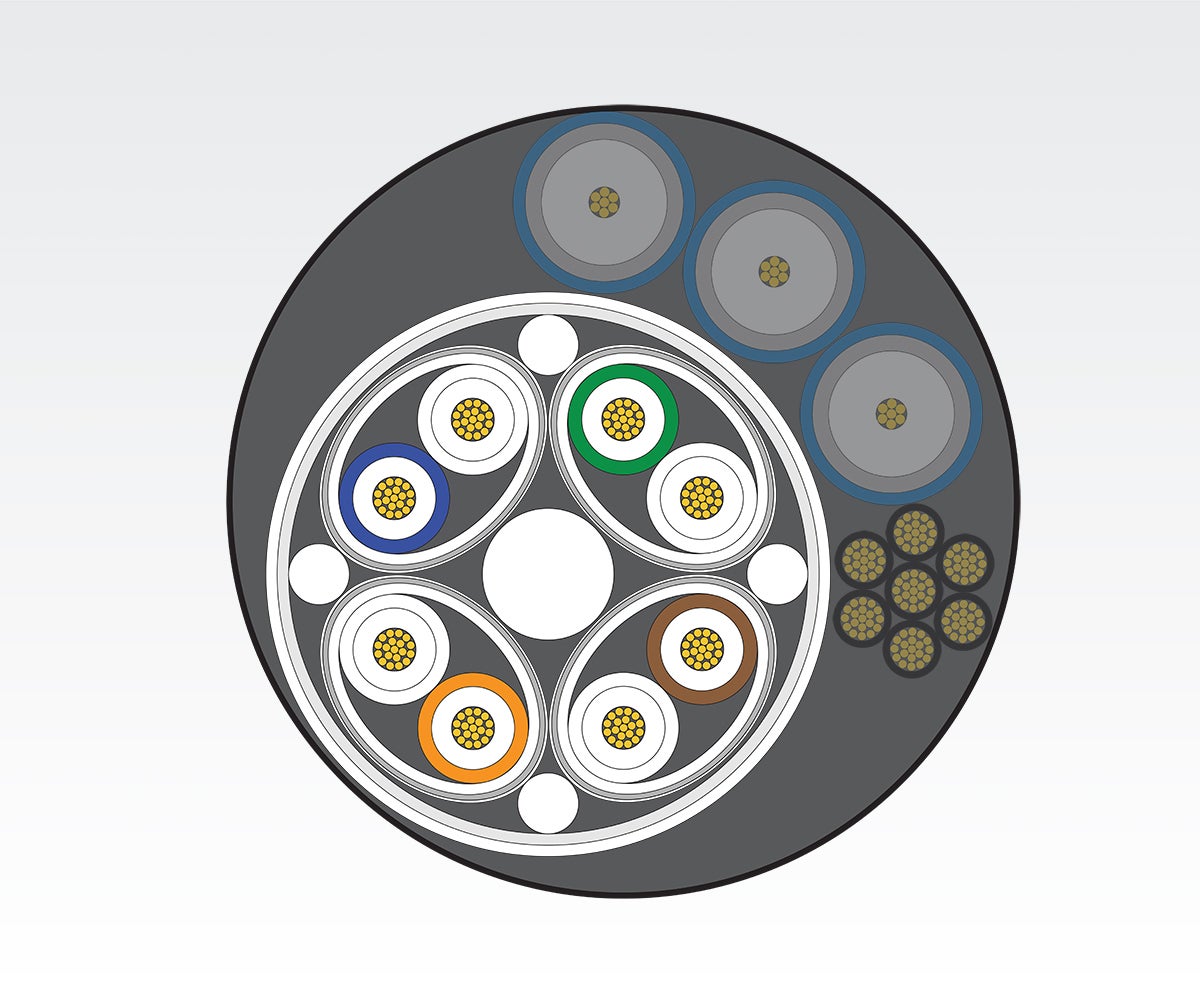

Standard harness cross-section with GORE DVI Cables (Digital Only)

Our single-link cables make it easier for design engineers to use them in standard DVI harnesses. They’re smaller, lighter and more flexible without sacrificing durability compared to substitutes. They fit easily into a harness cross-section with other components without getting damaged or breaking, saving you time and money on cable replacements.

Applications

Designed specifically for standard harnesses with digital components, GORE DVI Cables (Digital Only) provide satisfactory results in airborne applications, like:

- cockpit displays

- aircrew workstation displays

- mission systems

- weather mapping

Our cables can also be terminated with a variety of leading high-speed aerospace connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 contacts.

Features & Benefits

Unlike industry substitutes, GORE DVI Cables (Digital Only) are built with extremely durable materials proven to defend against complex maintenance and operational conditions, including:

- single-link DVI digital component design

- temperature- and abrasion-resistant materials

- chemically inert, EMI shielding materials

- lightweight with smaller diameters

To system architects and engineers, our reliable cables offer a host of benefits that improve their overall performance in defense aircraft, like:

- exceptional signal quality for high-speed video transfer

- support highest video resolution for optimal viewing on displays

- meet requirements for impedance control, insertion loss, skew, EMI shielding

- robust protection and stable performance in demanding radar environments

- easy fit into standard DVI harnesses with small, lightweight, flexible construction

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawing

These values demonstrate the electrical, mechanical and environmental performance of GORE DVI Cables (Digital Only) for defense aircraft. Download our data sheet for more cable characteristics, performance data, qualifications and part number. Also, fill out a short form for instant access to the drawing.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | <15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.07 (1.24) |

| Capacitance pF/m (pF/ft.) | 40.0 (12.0) |

| Maximum Skew ps/m (ps/ft.) Pair-to-Pair Within Pair | 52.50 (16.0) 13.12 (4.0) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper Alloy |

| Conductor Color-Coding | Blue/White, Brown/White, Green/White, Orange/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

Related Products

-

GORE SPP Type For High-Current Applications

-

GORE NOx and NH3 Catalytic Filter Bags

-

GORE Acoustic Vents for Industrial Applications

-

GORE Space Cables and Assemblies: Symmetrical Interconnects

-

GORE DVI Cables (Digital Only) for Defense Land Systems

-

GORE Shielded Twisted Pair Cables for Defense Air & Land