Gore (日本ゴア)

GORE Fibre Channel Cables for Civil Aircraft

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Fibre Channel Cables

Overview of Fibre Channel Cables

Today’s aircraft environment requires cables that can carry loads of data at higher speeds in advanced avionics. Aircraft cables are also subjected to challenging conditions and must be able to survive extreme temperatures, tricky wiring in less space, and harsh contaminants to name a few. Cables play a key role in system performance and can quickly fail if they get damaged or break, putting missions and aircrews at risk.

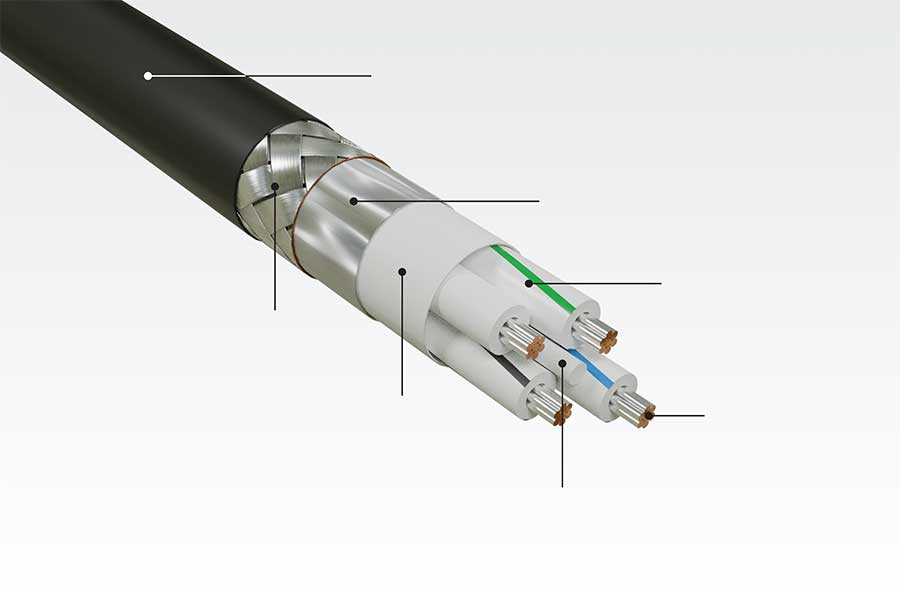

GORE Fibre Channel Cables enhance noise immunity and EMI suppression while maintaining consistent signal integrity at data rates up to 1 GHz. We use the field cancellation properties of a balanced quadrax cable design, so our high-speed cables can transmit 2 differential signals within the same shield without interfering with each other. Flight crews can always depend on receiving crucial information in real-time with our cables installed in the aircraft they fly.

Low-dielectric cable geometry.

SMALLER, LIGHTER & TOUGHER GEOMETRY

We also boost durability and protection with innovative fluoropolymer technologies that resist typical aircraft environments, like extreme temperature changes, aggressive chemicals, harsh contaminants and more. Our airborne fibre channel cables are built to perform reliably and last as long as the aircraft remains in service.

Without sacrificing toughness, these cables have a Gore-invented quadrax design that’s 40% smaller and weighs considerably less than dual twisted pair cables. Our low-dielectric cables are also more flexible with a tighter bend radius for easier wiring during routing in the smallest aircraft spaces.

Tough construction of GORE Fibre Channel Cables.

Applications & Connectors

GORE Fibre Channel Cables have been proven and trusted on the Falcon 7X among other commercial aircraft, making them a reliable interconnect for critical applications, like:

- active electronically-scanned arrays (AESA)

- cabin/flight management systems

- tactical aircraft moving maps

Our cables can be terminated with a variety of leading high-speed aerospace connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 contacts.

They can also be mated with commercially available connectors to create assemblies and optimize performance in the smallest possible package. Benefits include:

- Insert configurations maintain quadrax geometry through connector interface

- Improved Z° match minimizes reflections for clean eye patterns

- Standard size 22D contacts provide high reliability and ease of use

- Series 3 coupling provides enhanced EMI performance

Features & Benefits

We build GORE Fibre Channel Cables with rugged features proven to resist extreme aircraft conditions and environmental factors, including:

- original inventor of reduced quadrax design

- temperature- and abrasion-resistant materials

- chemically inert materials

For system architects and engineers, our aviation interconnects provide many benefits that improve their overall performance in aircraft, like:

- consistent signals up to 1 GHz with controlled impedance at 150 ohms

- enhanced noise immunity and EMI suppression

- resist hazardous aircraft environments and extreme flight conditions

- low-dielectric design is around 40% smaller than dual twisted pair constructions

- more weight savings in aircraft than other cable designs

- simpler and faster aircraft wiring from high flexibility and tight bending ability

- proven on many airborne platforms, like the Falcon 7X

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawing

These values demonstrate the electrical, mechanical and environmental performance of GORE Fibre Channel Cables for civil aircraft. Download our data sheet for more cable characteristics, qualifications and part number. Also, fill out a short form for instant access to the drawing.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1 |

| Standard Impedance Ohms | 150 ± 10 |

| Typical Operating Voltage Rating V | < 15 |

| Nominal Velocity of Propagation % | 87 |

| Nominal Time Delay ns/m (ns/ft) | 4.0 (1.22) |

| Capacitance pF/m (pF/ft) | 28.2 (8.6) |

| Typical Skew Within Pair ps/m (ps/ft) | 3.0 (0.9) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | FEP |

| Jacket Color | Black |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color-Coding | Black/White Stripe, Blue/White Stripe, Green/White Stripe, Solid White |

| Dielectric Material | Expanded PTFE |

| Temperature Range °C | -65 to +200 |

Related Products

-

GORE Cable Protection Systems for Civil Aircraft

-

GORE Microfiltration Media for Non-Implantable Medical Devices and In Vitro Diagnostics

-

GORE PEM for Water Electrolysis

-

GORE 1000 Series Gasket Tape

-

GORE 7 Series Microwave/RF Assemblies For Civil Aircraft

-

GORE Adhesive Series Protective Vents For Venting Solutions