Gore (日本ゴア)

GORE-FLIGHT 6 Series Microwave Assemblies For Civil Aircraft

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: 6 Series

Overview of 6 Series

Maintaining signal integrity under difficult aerospace environments is essential to the reliability of sophisticated avionics in commercial aircraft. Starting with installation and continuing through harsh flight conditions, like rapid temperature/pressure changes and potential contamination from fuels, oils, and fluids. At the same time, airframe assemblies must be both lightweight and durable to improve fuel efficiency and reduce operating costs.

In fact, we conducted independent studies and research showing that globally more than 75% of microwave/RF assemblies are frequently replaced because of damage during installation or operation. So, costs can quickly add up with replacing assemblies, extra labor, and more maintenance and downtime!

LIGHTWEIGHT SOLUTION WITH LOWEST INSERTION LOSS

GORE-FLIGHT Microwave Assemblies, 6 Series is proven to deliver the lowest insertion loss and more reliable VSWR before/after installation, providing stable and accurate performance compared to alternative airframe assemblies. Our rugged yet flexible airframe assemblies can easily withstand rigorous routing, maintenance activities, and flight conditions ensuring life-of-aircraft performance. They’re also 17% lighter weight compared to alternative designs, which improves fuel efficiency and increases cargo.

With this high level of performance, our 6 Series reduces costly production delays, field service frequency, and the need for purchasing replacement assemblies.

Commercial aircraft manufacturers no longer have to accept the practice of replacing microwave assemblies because they get damaged during installation. A fit-and-forget philosophy is now a reality because our 6 Series provides the most cost-effective, lightweight solution that ensures avionics performance for flight crews.

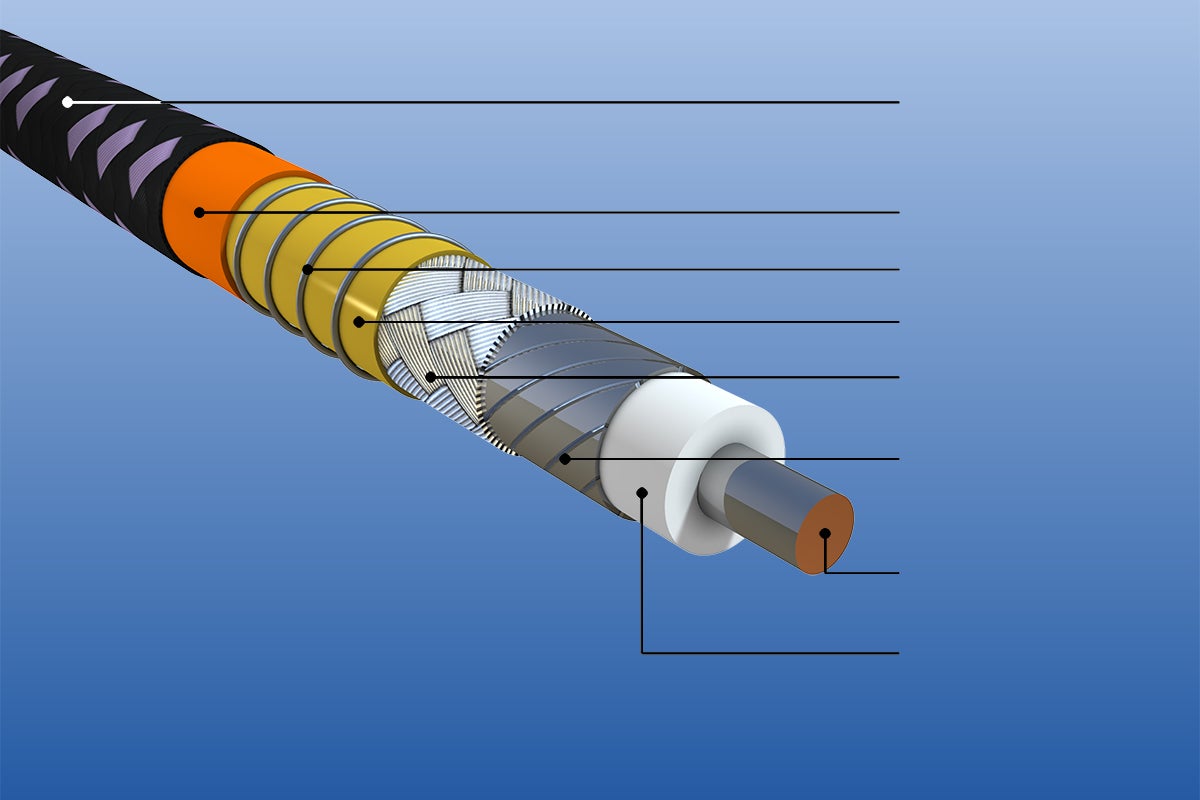

Rugged construction of GORE-FLIGHT Microwave Assemblies, 6 Series

Applications

GORE-FLIGHT Microwave Assemblies, 6 Series is engineered to perform reliably in commercial airborne applications, including:

- Ku-Band SATCOM antennas

- navigation / communications systems

- radar interconnects

Benefits

GORE-FLIGHT Microwave Assemblies, 6 Series provides system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- outstanding signal integrity in demanding aerospace environments during use and over time

- lowest insertion loss and more reliable VSWR before/after installation

- less interference among critical systems due to superior shielding effectiveness

- lower installation costs due to fewer failures and reduced aircraft production delays

- longer system life and reduced downtime with mechanically-rugged constructions

- durable vapor sealing prevents ingress of aircraft contaminants

- improved fuel efficiency and increased cargo with lightweight assembly

- increased design flexibility with robust, low-profile connector options

- proven performance with approved aerospace materials through qualification testing

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE-FLIGHT Microwave Assemblies, 6 Series.

| Electrical Property | Cable Type | |

|---|---|---|

| 6E | 65 | |

| Maximum Frequency Range (GHz) | 18 | |

| Typical VSWR through Max Frequency (Straight Connector) | 1.25:1 | |

| Guaranteed VSWR through Max Frequency (Straight Connector) | 1.40:1 | |

| Typical Insertion Loss (dB/m [dB/ft]) | 0.65 (0.20) | 1.12 (0.34) |

| Installed Insertion Loss (dB/m [dB/ft])a | 0.72 (0.22) | 1.16 (0.35) |

| Standard Impendance (Ohms) | 50 ± 1 | |

| Velocity of Propagation (Nominal) (%) | 86 | |

| Time Delay (Nominal) (ns/m [ns/ft]) | 4.0 (0.10) | |

| Capacitance (pF/m [pF/ft]) | 78.7 (24.0) | 75.8 (23.1) |

| Shielding Effectiveness (dB through Max Frequency) | 90 | |

| Dielectric Constant (Nominal) | 1.35 | |

a Based on a 10-foot assembly after 3 cycles through the installation simulator.

| Mechanical / Environemtnal Property | Cable Type | ||

|---|---|---|---|

| 6E | 65 | ||

| Jacket Material | Engineered Fluoropolymer | ||

| Jacket Color | Black and Purple | ||

| Center Conductor | Solid, Silver Plated Copper | ||

| Dielectric Material | ePTFE | ||

| Nominal Outer Diameter (mm [in]) | 8.9 (0.35) | 6.1 (0.24) | |

| Nominal Weight (g/m [lbs/1000 ft]) | 125.0 (84.0) | 60.0 (40.3) | |

| Minimum Bend Radius (mm [in]) | 48.3 (1.9) | 25.4 (1.0) | |

| Concentrated Load per MIL-T-81490, 4.7.18 (lbs) | > 150 | ||

| Temperature Range (°C)a | -55 to +125 | ||

Related Products

-

GORE Fiber Optic Cables for Defense Air & Land

-

GORE Space Cables and Assemblies: Datalines

-

GORE Type SPLD Space Cables For Geostationary Earth Orbit (GEO) Applications

-

GORE Microwave/RF Assemblies for Spaceflight Applications

-

GORE High Data Rate Cables

-

GORE Protective Vents Screw-In Series Help Outdoor Electronic Devices to Withstand All Weather Conditions And Temperature Changes