Gore (日本ゴア)

GORE HDMI Cables for Civil Aircraft

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: HDMI Cables

Overview of HDMI Cables

Higher Resolution Displays

With the demand for faster access to flight data and in-flight entertainment (IFE) on avionics digital networks and displays, cables must deliver the highest data rates and video resolution without failing. At the same time, cables need to be smaller and lighter to fit in tiny spaces of cockpits and cabins.

Meeting 1.4 Cat2 and 2.0 protocols, GORE HDMI Cables are known to transmit outstanding signals for high-speed data and video transmission up to 18 Gb/s without interruption. They also support 4K (2160p) video resolution so pilots can view critical flight information and passengers can watch IFE on crystal-clear aircraft displays.

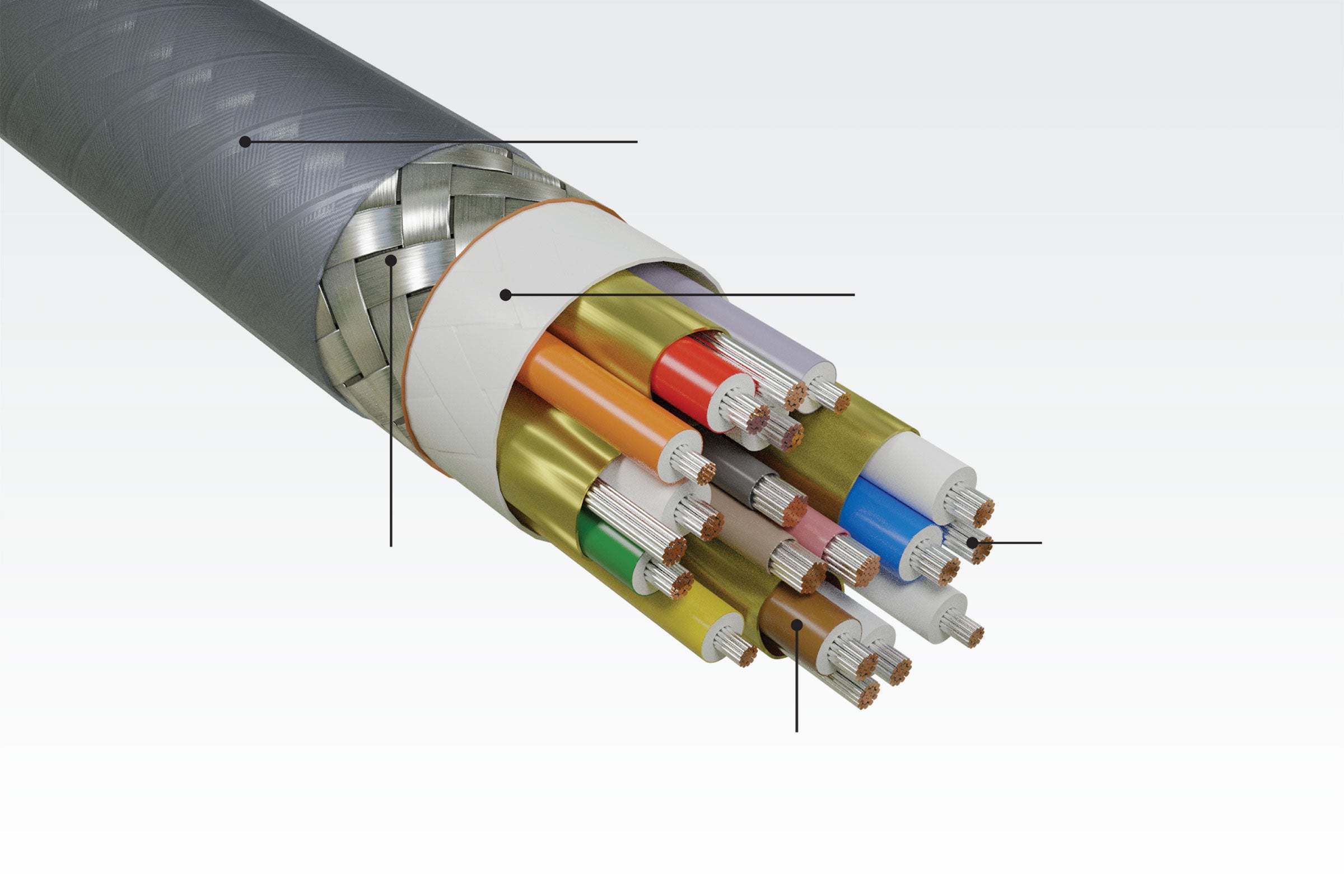

LOW WEIGHT WITH MORE DURABILITY

Size and flexibility matter when it comes to installing cables in airframes to avoid frequent failures, reduce replacement costs and keep aircraft weight down. Built with low-weight, flexible materials, our cable bundles offer smaller diameters with a tighter bend radius for less complicated routing in tight spaces that will please maintainers.

Though low in weight, they don’t compromise on durability and can easily sustain the demands of their surroundings where other cables have failed. All of these features translate to lifetime performance for operators and cost savings for original equipment manufacturers (OEMs).

Low-weight materials of GORE HDMI Cables.

Applications

For 1.4 Cat2 and 2.0 protocols, GORE HDMI Cables promise reliable high-speed data and video transmission with an optimal viewing experience in a variety of applications, like:

- consoles

- electronic flight bag (EFB)

- flight management systems

- glass displays

- HD streaming video systems

- IFE systems

- portable electronic devices

- sensor/processor connectivity

- weather mapping

Our cable bundles can also be terminated with a variety of leading high-speed aerospace connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 contacts.

Features & Benefits

Ideal for high-resolution displays, GORE HDMI Cables are built with distinct features that make them more durable against demanding environmental factors and interior aircraft conditions:

- abrasion- and temperature-resistant materials

- chemically inert materials

- small, low-weight cable diameters

Our aviation cable bundles offer system architects and engineers a number of benefits that ensure lifetime mechanical and electrical performance, like:

- meet 1.4 Cat2 and 2.0 protocol requirements

- support 4K video resolution for a rich, clear viewing experience

- outstanding signals for high-speed data and video transmission up to 18 Gb/s

- robust construction provides uncompromising durability in difficult conditions

- valued weight savings in commercial aircraft

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawing

These values demonstrate the electrical, mechanical and environmental performance of GORE HDMI Cables for civil aircraft. Download our data sheet for more cable characteristics, qualifications and part number. Also, fill out a short form for instant access to the drawing.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed Gb/s | Up to 18 |

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 230.0 (70.0) |

| Maximum Skew Within Pair ps/m (ps/ft.) | 15.0 (4.6) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | Gray |

| Conductor | Silver-Plated Copper or SPC alloy |

| Conductor Color-Coding | High-Speed Pairs: Blue/White, Brown/White, Green/White, Red/White SIngles: Orange, Violet, White, Yellow Triad: Gray, Pink, Tan |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |