Gore (日本ゴア)

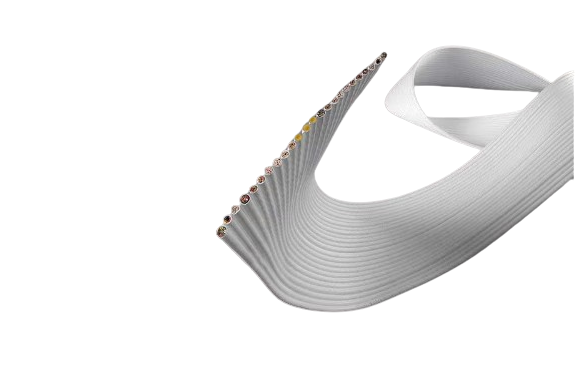

GORE High Flex Flat Cables for Semiconductor Production Equipment

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: High Flex Flat Cables

Overview of High Flex Flat Cables

SIGNAL INTEGRITY IN COMPLEX ENVIRONMENTS

Cleanliness, durability and reliability are essential for flat cable solutions in semiconductor production equipment bound for complex cleanroom and vacuum environments. Cables are also expected to move faster with high flex life performance while delivering reliable signal transmission at higher speeds.

GORE High Flex Flat Cables offer improved signal integrity, more durability and can be reliably used in any energy chain or cable track. Our long-lasting flex cables enable higher yields and help reduce particle formation while optimizing flex life in high-precision, automated machinery applications.

LOWEST PARTICULATION & OUTGASSING LEVELS

As cables for automation equipment move, flex and rub against a flexible cable carrier, their construction materials often shed particles that can contaminate cleanroom environments and damage sensitive components. GORE High Flex Flat Cables have been certified to ISO 14644-1 Class 1 cleanroom applications by the Fraunhofer Institute in Germany according to the probability calculations defined in VDI Guideline 2083 and ISO 14644-1.

Our high flex flat cables offer the lowest outgassing properties that can ensure optimal results and protect sensitive processes, like advanced inspection and metrology performed in vacuum environments.

IMPROVED CABLE MANAGEMENT

GORE High Flex Flat Cables can substantially improve cable management and reduce the total cost of ownership. They have a proven flex life of more than 20 million cycles and reliable signal integrity for data transmission. Also, the flat construction eliminates dividers and shelves in a traditional cable chain, reducing the cable system’s total weight or allowing a smaller flexible cable chain to be used.

When it comes to the size of a flat cable vs. round cable, the lightweight, durable materials in our flat cables are 1/2 to 1/3 the thickness of most round cable materials and meet UL requirements for safety and flame resistance. With a proven flex life, our low-bend radius flex cables make installation much easier and have performance characteristics that give system designers peace of mind.

Applications of High Flex Flat Cables

GORE High Flex Flat Cables solve many common issues with particulation, vibration, size, weight and costly maintenance in a variety of semiconductor applications, including:

- cleanroom automation

- advanced packaging equipment

- front-end wafer inspection

- wafer metrology equipment

- semiconductor automated optical inspection (AOI)

- semiconductor processing equipment

- linear motion stages

- pick & place equipment

- wafer handling

- flat panel display (FPD) manufacturing equipment

- CMOS image sensor (CIS) packaging equipment

- lens manufacturing equipment

Features & Benefits of High Flex Flat Cables

For continuously demanding operation, GORE High Flex Flat Cables are designed with unique features that make them more durable, including:

- flat cable construction eliminates the need for cable chain

- low-friction, non-particulating materials

- non-outgassing materials available

- temperature-resistant and chemically inert materials

Our reliable high flex life cables provide manufacturers with many benefits that ensure high performance in semiconductor automation equipment, like:

- increased throughput and yield

- less maintenance, downtime and total cost of ownership

- fully custom flex cable solutions

- reliable signal integrity

- certified for ISO Class 1 cleanroom and vacuum environments

Technical Specs

These values demonstrate the electrical, mechanical and environmental performance of GORE High Flex Flat Cables for semiconductor production equipment in cleanroom and vacuum environments.

| Elec. / Mech. / Environ. Property | Value |

|---|---|

| Maximum Accelerationa g (m/sec2) | 4.0 (40) |

| Speed m/sec | 4.0 |

| Jacket Material | Expanded PTFE Composite |

| Jacket Color | White |

| Core Types | Signal, Power, Fiber Optic, Pneumatics |

| Maximum Self-Supporting Stroke Length mm (in) | 500 (20) |

| Overall Width mm (in) | 300 (12) |

| Minimum Bend Radius mm (in) | 50 (2) |

| Flex Life (Cycles) (BR. 50 mm up to 4G Accelerations) | > 20 million |

| Temperature Range °C | -40 to +200 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulationb % (ISO14664-1 / VDI Guideline 2083) | < 0.1 |

| Outgassingc mBar liter/sec cm2 (AMU) H20 CxHyv CxHynv | < 6 x 10-10 < 1 x 10-11 (< 100) < 1 x 10-12 (> 100) |

How to Customize or Buy

As an industry leader for long-lasting flex cable solutions, we offer electrical and pneumatic lines in flat cable assemblies that can be custom-fit to meet your exact high flex cable specifications for cleanroom and vacuum environments.

Use our easy online design tool to choose from the most common industry components and build your high-flex robotic cable. Once you submit the form, a Gore representative will contact you.

If you need help with a flex cable design to meet your specific equipment needs or to order the standard version of our robotic cables, including options for higher acceleration and speed, contact us today.