Gore (日本ゴア)

GORE High-Frequency Cable Assemblies for Ka Band Frequencies

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: High-Frequency Cable

Overview of High-Frequency Cable

Proven performance and reliability for 32 GHz spaceflight applications

Failure isn’t an option in space, nor is it an option for cables used in space. These cables must endure take-off and harsh landings, stay reliable in use throughout the mission, and never require maintenance. After all, there’s no quick fix millions of miles from home.

Gore’s High-Frequency Cable Assemblies for Ka Band Frequencies (Type 5G Series of GORE® Spaceflight Microwave/RF Assemblies) are qualified for spaceflight applications in three separate phases — integration, launch, and in-orbit — to ensure consistently reliable performance for the duration of the mission.

Unlike the standard bifurcated contact used in test connectors, the robust connectors of the Type 5G Series withstand the vibration of launch and orbit without compromising signal performance. In addition, the low profile of these connectors increases flexibility during the layout process of satellite design.

With superior radio frequency performance at 32 GHz, the cables are optimized for Ka band uplink and downlink applications.

Features & Benefits

Gore’s High-Frequency Cable Assemblies for Ka Band Frequencies have a durable cable construction engineered to withstand the rigors of space travel, from takeoff to landing and back. The assemblies deliver:

- reliable signal integrity with excellent insertion loss and return loss

- outstanding shielding effectiveness

- increased flexibility in design layout with robust, low-profile connector solutions

- proven performance from qualification in integration, launch, and in-orbit phases

Additionally, the assemblies are Globally available from manufacturing facilities in the United States and Europe.

Specifications

Gore’s High-frequency Cable Assemblies for Ka Band Frequencies have these general specifications:

- Frequency Range: DC – 32 GHz

- Optimized Frequencies: 17.5 GHz – 22 GHz, 27 GHz – 32 GHz

- Impedance: 50 ±1 ohms

This chart outlines additional specifications, like mass, minimum bend radius, and jacket material. Note that all specifications are based on 23.6 in (600 mm) long qualification assemblies; DC to 32 GHz. Guaranteed figures are available on request.

| Property | Value |

|---|---|

| Cable Part Number | 5G |

| Cable Outer Diameter (nom) | 0.170 in (4.3 mm) |

| Mass (nominal) | 13 g/ft (42 g/m) |

| Minimum Bend Radius | 1.0 in (25.4 mm) |

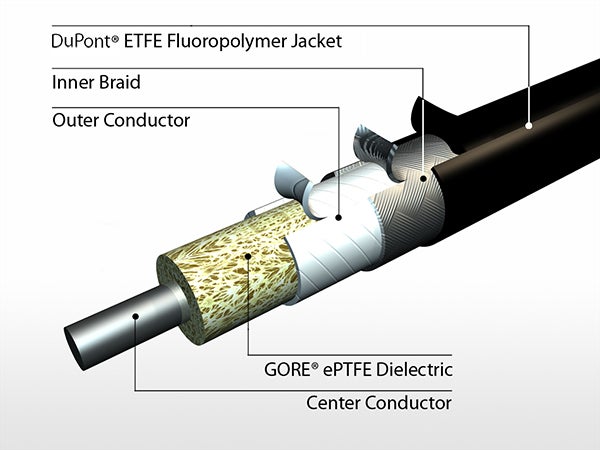

| Center Conductor | Silver-plated copper wire, solid |

| Dielectric | Expanded PTFE (ePTFE), tape wrapped |

| Electrical Shield | Silver-plated flat copper wire, helically-wrapped |

| Mechanical Braid | Silver-plated round copper wire, braided |

| Jacket | Extruded DuPont™ ETFE fluoropolymer, black |

Qualifications

The cables are fully qualified for integration, launch and in-orbit phases, along with multiple configurations and wide temperature ranges.

| Property | Value |

|---|---|

| Integration, Launch and In-Orbit Phases | Fully Qualified |

| Configurations | 5GZMQZMQ & 5GZMQZQA Cable Assemblies |

| Temperature Range | -55°C to +155°C |

| Qualification Test Report No. | ET-12036 |