Gore (日本ゴア)

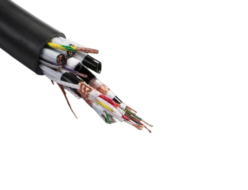

GORE High Speed Data Cables for Semiconductor Production Equipment

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: High Speed Data Cables

Overview of High Speed Data Cables

RELIABLE HIGH DATA RATE SIGNAL TRANSMISSION

In today’s automation equipment, cables must operate at higher speeds without compromising signal integrity while meeting new data and video interface protocols. They must also move faster with longer flex life in complex semiconductor environments.

With a proven track record, GORE High Speed Data Cables provide peace of mind when reliable system performance and equipment uptime are critical. They’re known to transmit non-stop signals up to 1 GHz while minimizing bit errors in moving applications like motion control and vision systems. They also meet, even exceed, protocol requirements, like Ethernet, FireWire®, USB and CoaXPRESS. Their lightweight design offers superior flex life performance and maximum resistance to severe mechanical and environmental stresses.

LIGHTWEIGHT WITH LONG FLEX LIFE

Most standard cables on the market today are designed for static environments, and when put in motion environments, they fail to meet industry specifications. Also, insertion loss increases when these cables are flexed.

You can flex GORE High Speed Data Cables beyond 10 million cycles without worrying about electrical failure or mechanical degradation. You can feel confident that they’ll deliver stable signal transmission during flexure over the life of the equipment. Plus, our lighter cable design reduces weight and stress, and a small bend radius of 50 millimeters (2 inches) makes them easier to install in your equipment.

LOWEST LEVELS OF PARTICULATION

Our cables are certified to ISO Class 1 cleanroom environments by the Fraunhofer Institute in Germany according to the probability calculations defined in VDI Guideline 2083 and ISO 14644-1. The institute determined that GORE High Speed Data Cables have less than 0.1% probability of emitting particulates, maintaining the lowest levels for repeated flexing.

Applications

Maintaining stable signal transmission, GORE High Speed Data Cables are reliably used in semiconductor production equipment, including:

- High data rate links

- Image scanning

- Machine vision

Features & Benefits

We’ve engineered GORE High Speed Data Cables with unique features that make them more durable in harsh cleanroom environments, including:

- low-friction, non-particulating materials

- temperature-resistant materials

- chemically inert materials

Our reliable cables provide manufacturers with many benefits that improve semiconductor production equipment performance, like:

- meet or exceed protocol requirements, like Ethernet, FireWire®, USB, CoaXPRESS

- non-stop signal transmission up to 1 GHz, minimizing bit errors or data loss

- proven high flex life beyond 10 million cycles with stable electrical performance

- no particulation due to unique jacket and shielding materials

- easy installation from lightweight design with tight bending down to 50 mm (2 in)

- reduced maintenance, downtime and total costs over the equipment lifecycle

- ISO Class 1 certified for high data rate environments

How to Customize or Buy

Lightweight GORE High Speed Data Cables are the perfect choice for moving systems that demand high flex life and reliable signal transmission over time in complex automation environments. We offer electrical and pneumatic lines that can be custom-fitted to meet your exact high data rate requirements.

Build your own cable using our easy online design tool and choose from the most common industry components. Once you submit the form, a Gore representative will contact you.